Wood drying and anticorrosive treatment method

A technology for anti-corrosion treatment and wood drying, which can be used in wood drying, drying solid materials, drying gas layout, etc., and can solve problems such as damage to wood structure and morphology and environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

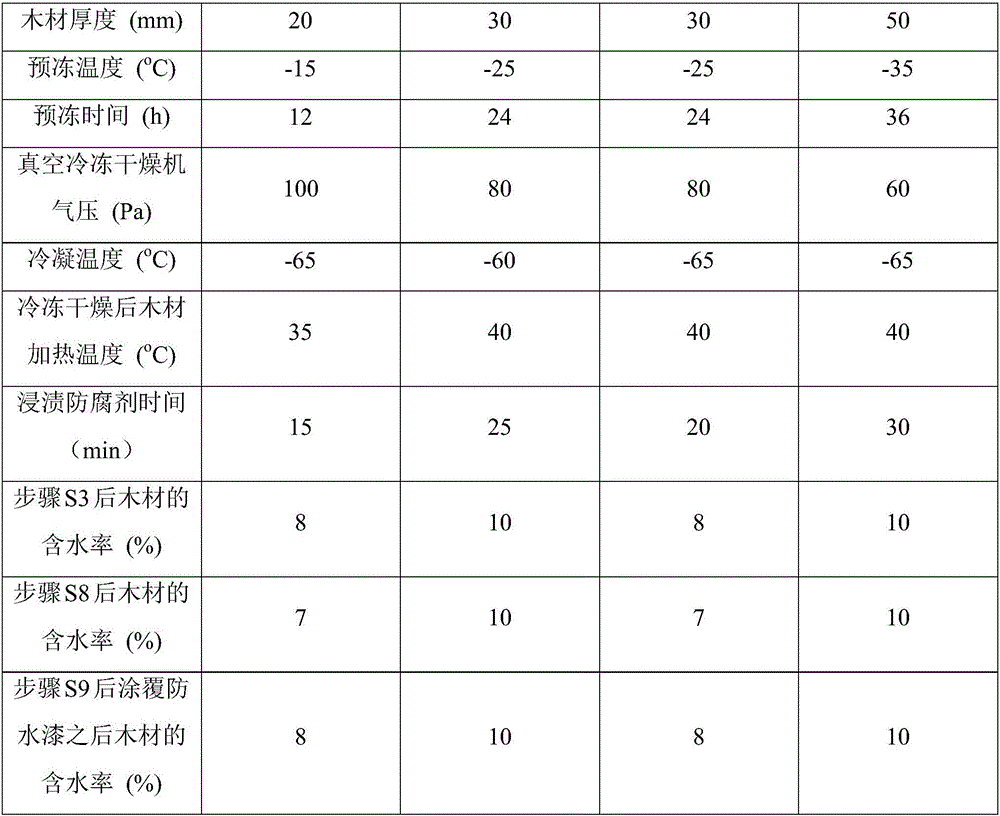

Embodiment 1

[0024] S1: Process the wood to a plate with a thickness of a mm, and load it neatly in a single row on the heating device of the wood pre-freezing-vacuum freeze-drying machine. After loading, close the airtight door of the equipment;

[0025] S2: Pre-freeze the wood, start the pre-freezing device, pre-freeze the wood under normal pressure, the temperature is b°C, and the time is ch;

[0026] S3: Vacuum freeze-drying, turn on the vacuum pump to reduce the ambient pressure in the freeze dryer, and maintain it at d Pa, set the condensation temperature to e°C, and heat the board through the heating device, so that the moisture in the wood is directly sublimated from solid ice to gaseous state Water vapor realizes wood drying; when the moisture content of wood drops to f%, the freeze drying ends;

[0027] S4: Heat up, increase the ambient pressure and temperature of the vacuum freeze dryer, turn on the heating equipment to slowly heat the wood, the temperature of the wood rises to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com