Wood drying method

A technology of wood drying and drying method, applied in the field of wood drying, can solve the problems of many correction coefficients, large errors, inaccurate results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] Take fir as an example below to illustrate the working process of the wood drying of the present invention.

[0081] The wood drying method of the present invention is applicable to the drying of other types of wood, such as poplar, pine, willow, etc., except for drying Chinese fir.

[0082] 1. Wood pretreatment

[0083] A) Chinese fir timber to be dried is cut into wood sections according to the required length, and the length L of the wood sections is 2m;

[0084] B) Take a representative piece of wood from the Chinese fir wood to be dried, and weigh its wet weight (G 湿 ), then put the wood in an oven with a drying temperature of 103±2°C, and weigh it every 6 hours. When the difference between the weights of two consecutive weighings is less than 0.02g, the wood is considered to be absolutely dry. At this time, the wood The weight is the absolute dry weight of the wood (G 干 ), the volume of wood is the dry volume (V).

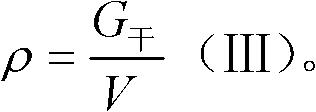

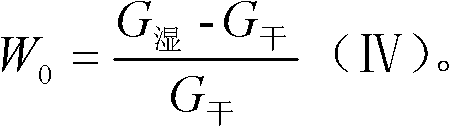

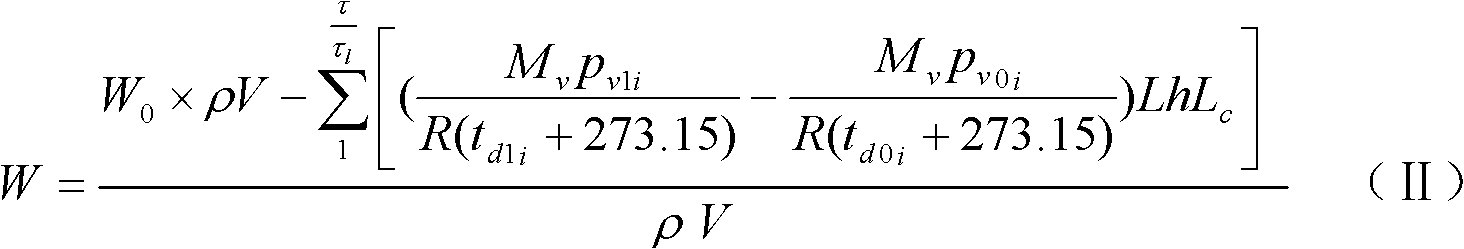

[0085] C) According to the density calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com