Shaft flow monitoring system and flow and water content interpretation method

A flow monitoring and wellbore technology, used in surveying, earthmoving, wellbore/well components, etc., can solve problems such as stall, measurement accuracy and measurement stability impact, blowout, etc., to achieve easy layout, save mining costs, Accurate effect of air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

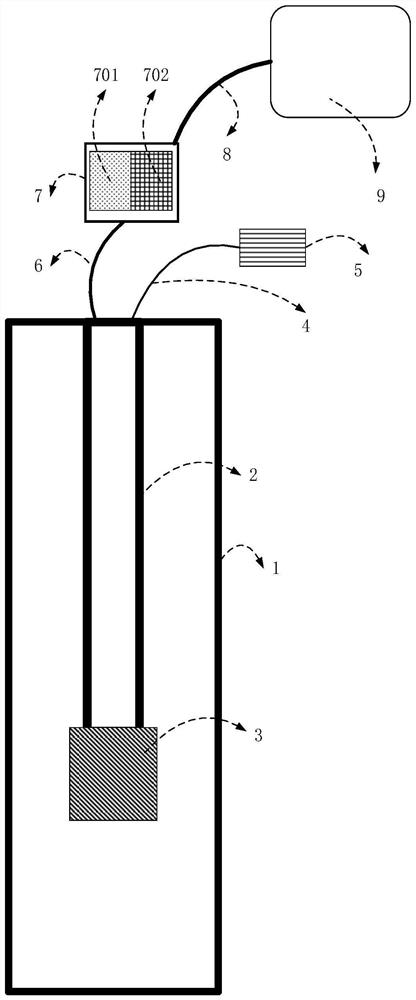

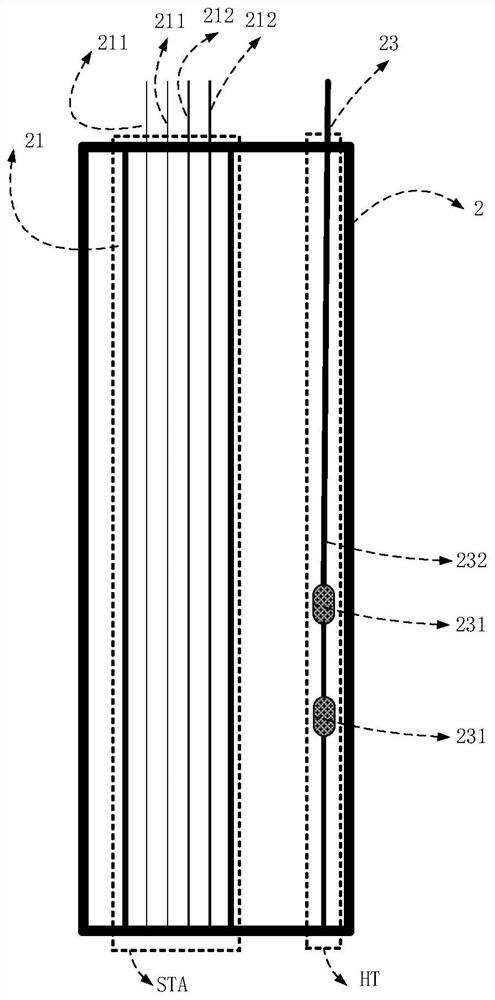

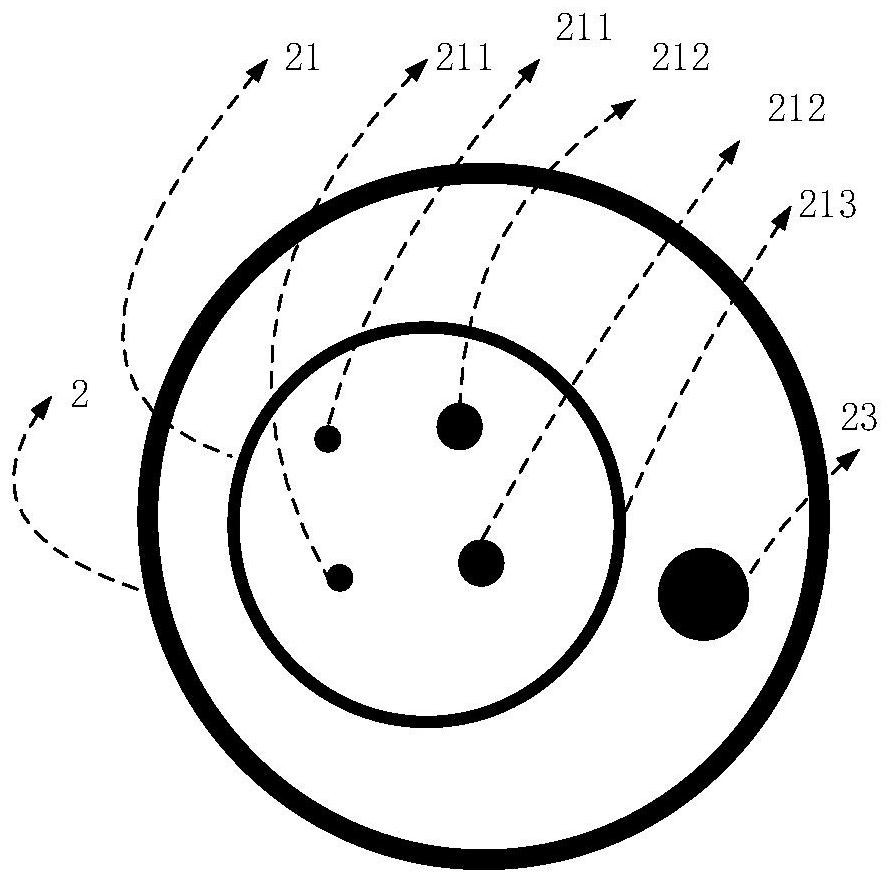

[0063] like figure 1 As shown, a wellbore flow monitoring system, the monitoring system includes a multifunctional carbon fiber optical fiber composite rod 2, an oil well pump 3, a ground pulse heating control system 5, a ground optical fiber monitoring signal acquisition system 7, and computer analysis for optical fiber monitoring data processing and interpretation system9.

[0064] The oil pump 3 is connected to the bottom end of the multifunctional carbon fiber optical fiber composite rod 2 and lowered into the wellbore 1, and the ground pulse heating control system 5 is connected to the top end of the multifunctional carbon fiber optical fiber composite rod 2 through the ground heating control integrated cable 4.

[0065] The ground optical fiber monitoring signal acquisition system 7 is connected to the top of the multifunctional carbon fiber optical fiber composite rod 2 through the ground optical cable 6, and the optical fiber monitoring data processing and interpretati...

Embodiment 2

[0084] like Figure 4 As shown, a method for interpreting the flow rate and water cut rate of oil-water-gas three-phase fluid in an oil well is carried out using the wellbore flow monitoring system described in Example 1. The specific steps are as follows:

[0085] 1) Start the oil well pump 3 to carry out the liquid drainage work, and collect the background temperature information and sound wave information generated when the fluid in the wellbore 1 flows stably through the multifunctional carbon fiber optical fiber composite rod 2 in real time. The background temperature information refers to that measured before heating The temperature curve formed by the wellbore fluid temperature changing with the well depth;

[0086] 2) Perform interval pulse heating on the fluid at point Y of the wellbore. The point Y corresponds to the location of the HT thermal excitation unit, so that the temperature of the fluid downstream of point Y shows a pulse change, and record the heating powe...

Embodiment 3

[0104] This embodiment is a monitoring data interpretation method for the fluid flow rate and water content of a self-spraying well. The difference from Embodiment 1 is that there is no oil well pump 3 at the lower end of the multifunctional carbon fiber optical fiber composite rod 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com