Coal mine underground fire monitoring system

A monitoring system and coal mine technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of inability to realize early fire prediction of belt conveyors, and achieve the effects of prolonging life, saving costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with the following examples.

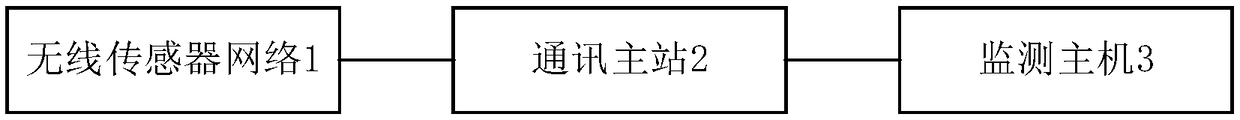

[0016] see figure 1 , a coal mine underground fire monitoring system, the coal mine underground fire monitoring system includes: a monitoring host 3, the monitoring host 3 is located on the ground and is installed with system monitoring software and a background database, and the monitoring host 3 is used to receive underground safety data and issue monitoring instructions; communication The master station 2, the communication master station 2 communicates with the monitoring host through the industrial Ethernet network, and is used to receive and transmit underground safety data and monitoring instructions; and, the wireless sensor network 1, the wireless sensor network 2 is located in the coal mine sensing area, through The master station 2 communicates with the monitoring host 3, and includes a plurality of sensor nodes, the sensor nodes are used to collect coal mine safety data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com