Monitoring system based on carbon fiber optical fiber composite rod and monitoring data interpretation method

An optical fiber composite and monitoring system technology, which is applied to measurement devices, earth-moving drilling, and optical devices to transmit sensing components, etc., can solve problems such as inability to meet, limited monitoring functions of oil production systems, etc., to improve production efficiency, easy to arrange, The effect of simplifying the layout process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

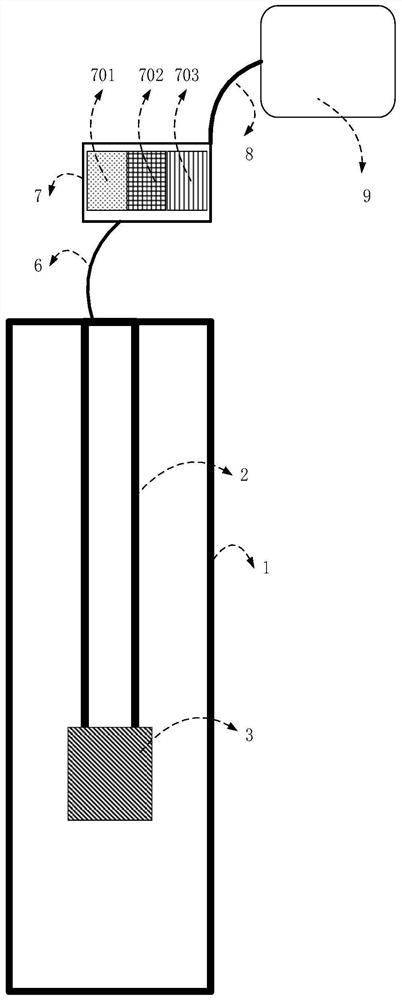

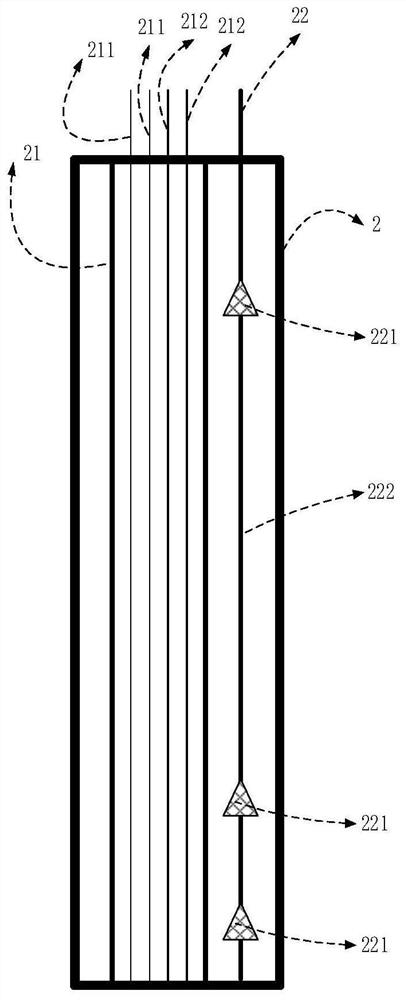

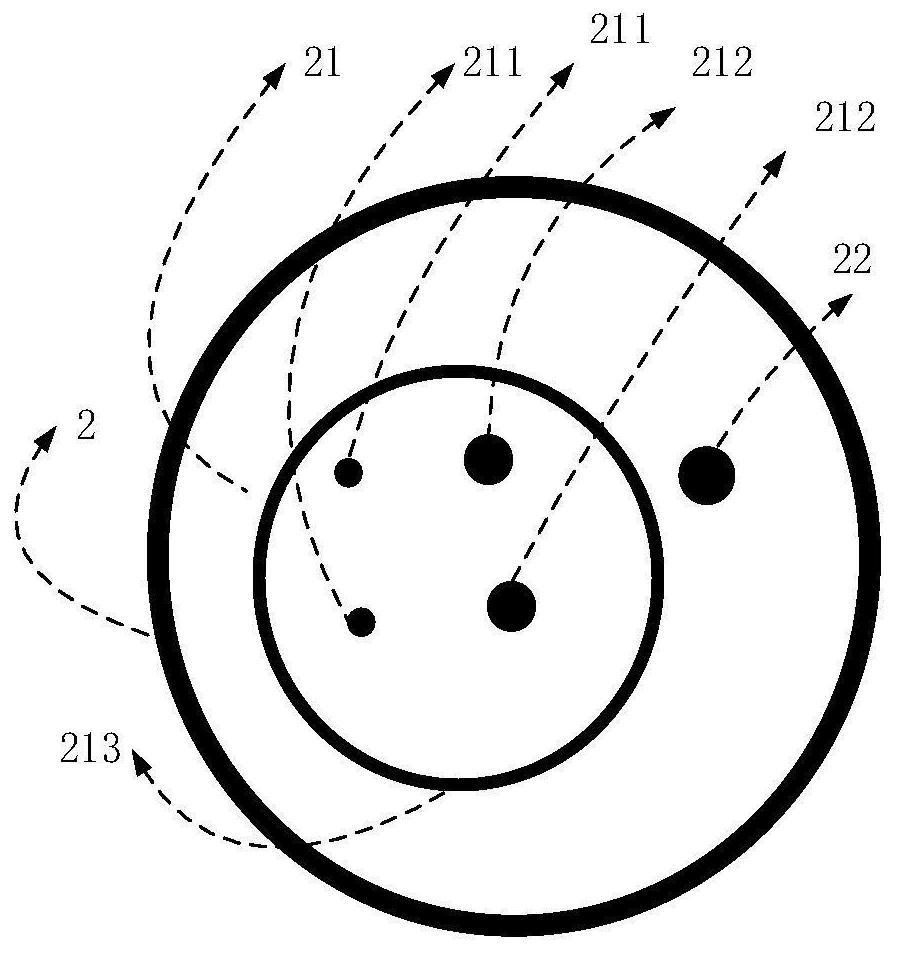

[0071] Such as figure 1 As shown, the monitoring system based on carbon fiber optic composite rod includes multifunctional carbon fiber optic composite rod 2, oil well pump 3, ground optical fiber monitoring signal acquisition system 7 and computer analysis system 9 for optical fiber monitoring data processing and interpretation.

[0072] The oil well pump 3 is connected to the bottom end of the multifunctional carbon fiber optical fiber composite rod 2 and lowered into the wellbore 1 .

[0073] The ground optical fiber monitoring signal acquisition system 7 is connected to the top of the multifunctional carbon fiber optical fiber composite rod 2 through the ground optical cable 6, and the optical fiber monitoring data processing and interpretation computer analysis system 9 is connected to the ground optical fiber monitoring signal acquisition system 7 through the ground data communication cable 8 connected.

[0074]The ground optical fiber monitoring signal acquisition syst...

Embodiment 2

[0095] This embodiment is a method for interpreting the wellbore production status monitoring data of a single oil layer pumping well. The monitoring system based on the carbon fiber optical fiber composite rod described in Embodiment 1 is used as an example to comprehensively interpret the downhole production dynamics, and the monitoring involved in the present invention The data interpretation method is described in detail, and the specific steps are as follows:

[0096] 1) The oil well pump 3 is started to discharge liquid, and the sound wave information, temperature information and pressure information generated when the fluid in the wellbore 1 flows are collected in real time through the multifunctional carbon fiber optical fiber composite rod 2 .

[0097] 2) Interpretation method for monitoring data of fluid flow and water cut in single-layer pumping wells: In order to reduce the ambiguity of fluid flow and water cut, it is necessary to perform multi-parameter fusion inte...

Embodiment 3

[0113] Different from Embodiment 2, this embodiment is a monitoring data interpretation method for fluid flow interpretation of multi-layer pumping wells. The difference from Embodiment 2 is that the depth range between two adjacent oil layers is required Inside, at least one fiber grating pressure gauge 221 is arranged at a corresponding position in the multifunctional carbon fiber optical fiber composite rod 2 .

[0114] Because a single oil layer is produced, the fluid flow in the entire wellbore 1 remains constant. When multiple oil layers are produced, the flow rate increases gradually from bottom to top, and the temperature and pressure between each oil layer are different, so at least one fiber grating needs to be arranged The pressure gauge 221 measures the pressure and temperature data between two adjacent oil layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com