Method for preparing zebra-strip upright post material for wood stair by bamboo recombination process

A technology for recombining bamboo and zebra, which is applied in the manufacture of tools and wood processing equipment, etc., can solve the problems of long production cycle, tight source of raw materials, and high cost, and achieve the effect of low price, abundant resources, and reduced manufacturing cost

Inactive Publication Date: 2011-01-05

BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

View PDF5 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of material is mostly produced from natural forests, which has the problems of long production cycle, shortage of raw material sources and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Login to View More

Abstract

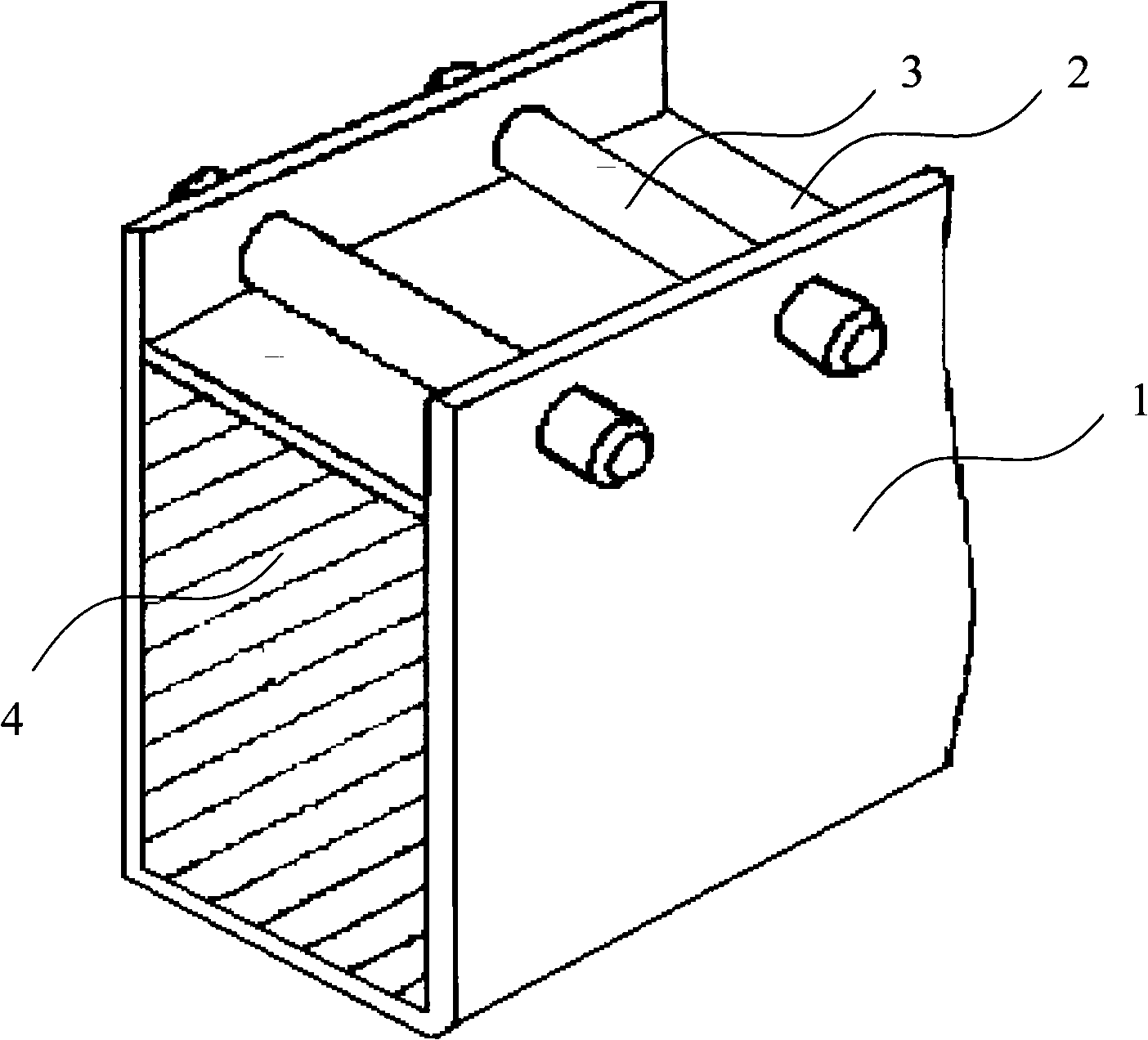

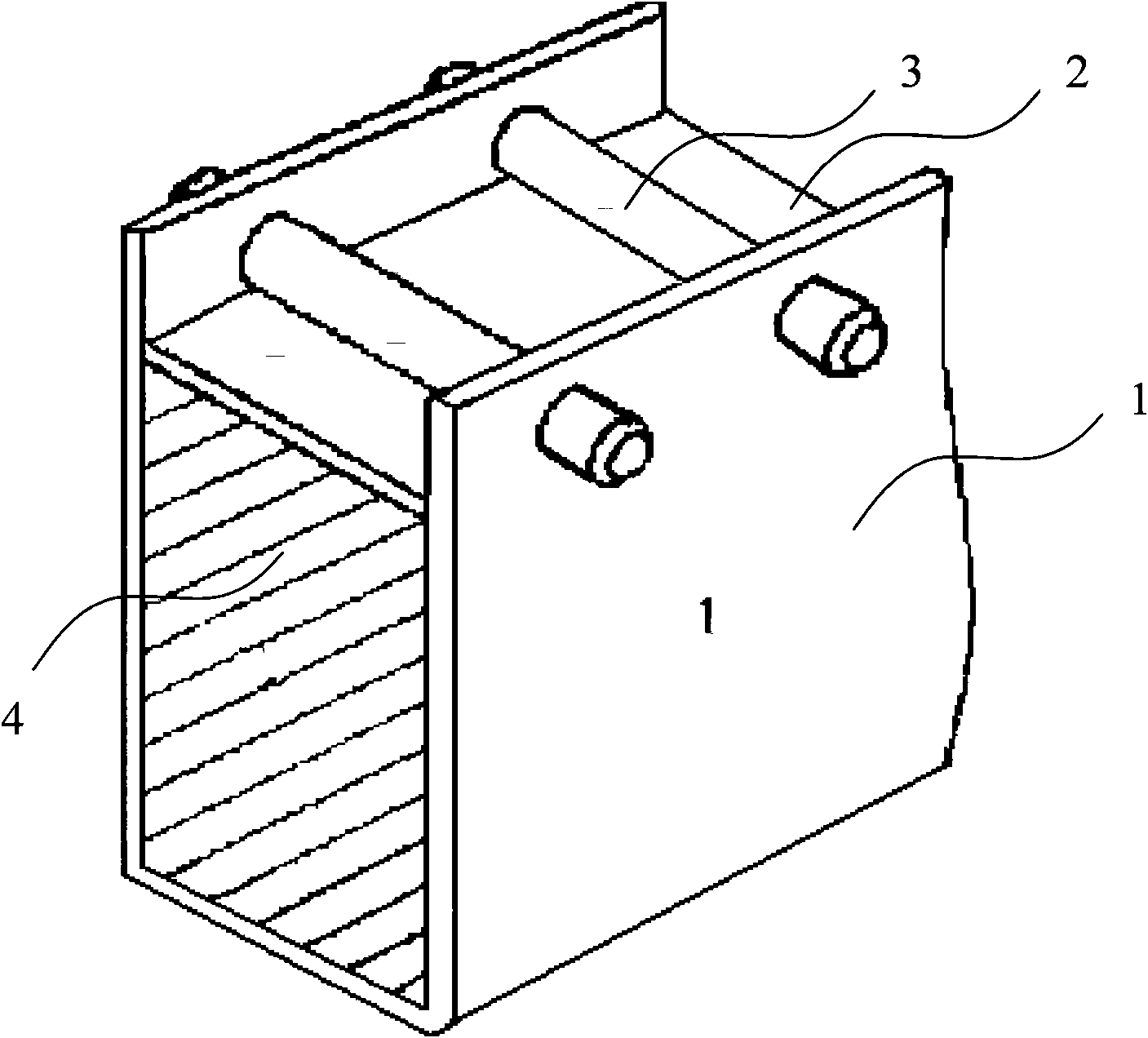

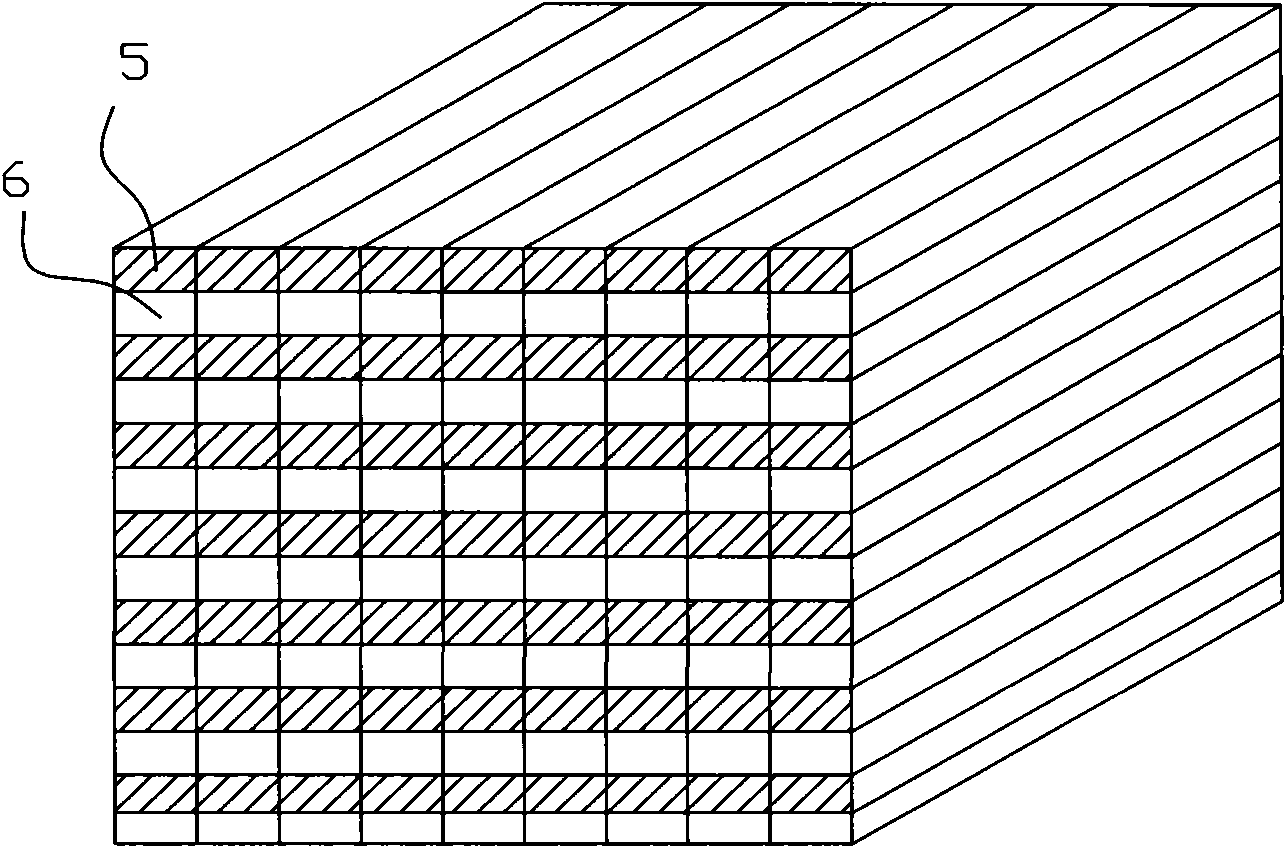

The invention discloses a method for preparing a zebra-strip upright post material for a wood stair by using moso bamboo. The method comprises the following steps of: 1, cutting 4 to 6-year old moso bamboo and cutting bamboo poles into bamboo sections with predetermined specifications; 2, splitting and breaking the bamboo sections; 3, putting a part of carded moso bamboo sections into a wood cooking kettle for overheat steam carbonization; 4, drying the carbonized carded moso bamboo sections and the remaining non-carbonized moso bamboo sections into a wood drying kiln for drying respectively;5, soaking the dried carded moso bamboo sections and the carbonized moso bamboo in a phenolic resin respectively; and 6, laminating and assembling the carded moso bamboo sections and the carbonized moso bamboo soaked with phenolic resin glue solution in a preset assembling mode and pressurizing and compacting the laminated and assembled carded moso bamboo sections and carbonized moso bamboo in a cold press. A recombined moso bamboo laminated material with attractive zebra strips prepared by the method can meet the use requirement on the upright post of the wood stair.

Description

A method of manufacturing zebra stripe wooden stair column material by using recombined bamboo technology technical field The invention relates to a new processing method for manufacturing zebra-striped wooden stair column materials by using recombined bamboo technology. Background technique Wooden stairs have long been a common high-end product in wooden houses in western economically developed countries. In mainland China, with the rapid economic development and the improvement of people's living standards in the past 40 years, some people who got rich first are putting Residential interest turns to duplex and villa buildings. The domestic demand for wooden stairs has been growing quietly, and a wave of buying wooden stairs is gradually heating up in various places. At present, most of the wooden staircase components used in China are made of high-grade wood. Most of these materials are produced from natural forests, which have the problems of long production cycle, s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B27M3/12

Inventor 袁东黄晓东李晓旭姜忠斌虞华强

Owner BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com