Processing equipment and processing method for improving wood breathability

A technology of wood treatment and treatment equipment, which is applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of affecting the drying quality of dried wood, slow movement of moisture inside wood, and easy drying defects, etc., to achieve the improvement of ultrasonic treatment Efficiency, reduction of drying defects, and shortening of the drying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

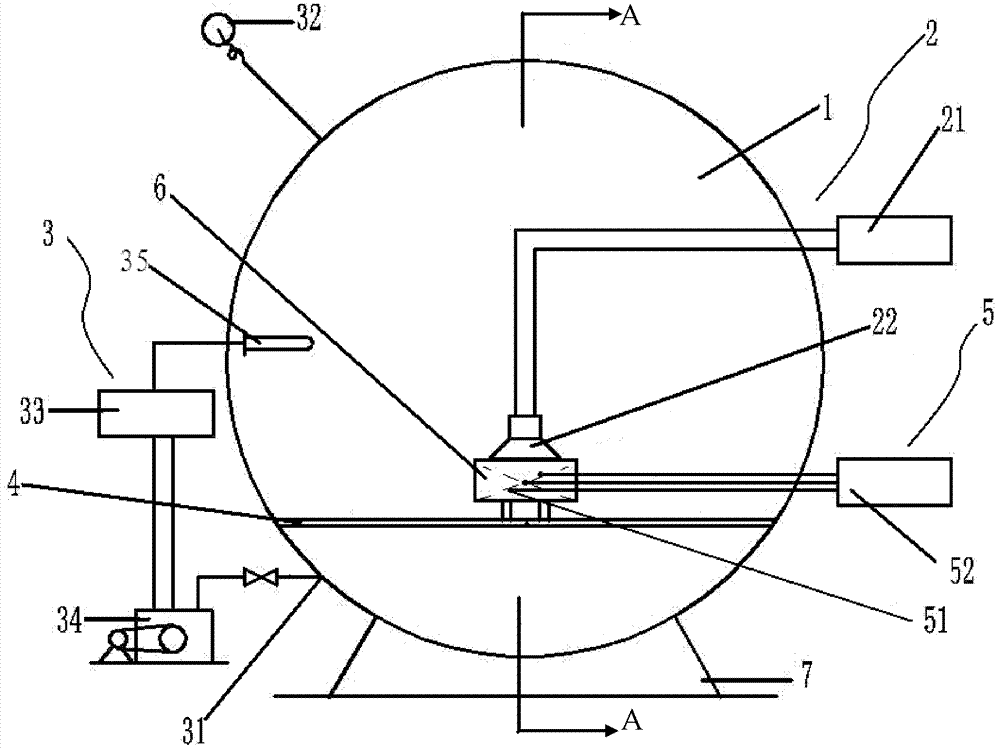

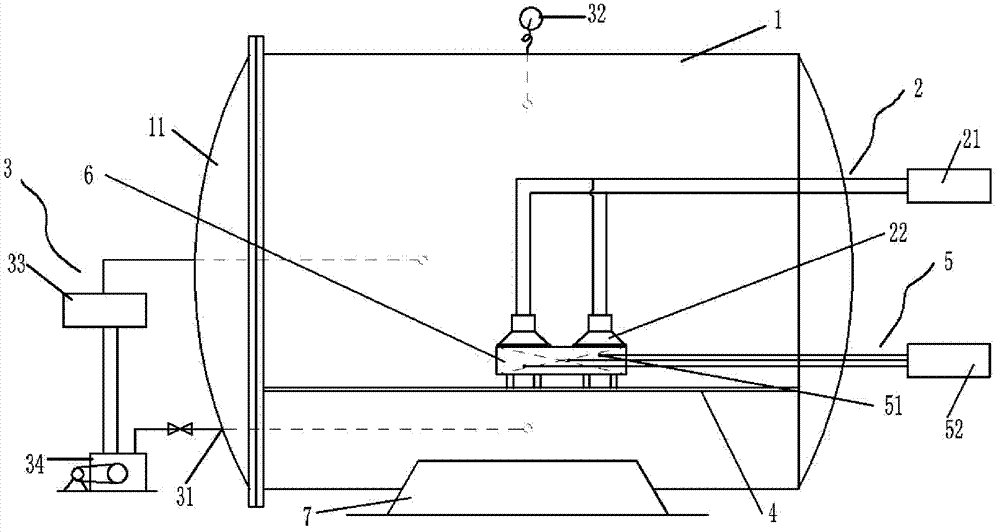

[0066] Get the eucalyptus wood section that size is 200mm (length) * 100mm (width) * 40mm (thickness) and carry out ultrasonic treatment, improve the gas permeability of eucalyptus wood.

[0067] 1. Drill holes in the plane formed by the length and thickness of each eucalyptus wood segment, and the horizontal distance between two adjacent drill holes along the length direction of the wood segment is 4cm; adjacent along the thickness direction The vertical spacing between two boreholes is 1cm; Then the temperature sensor that diameter is 1mm is installed in the aperture of described wood section, 3 layers of temperature sensors 51 are evenly arranged in the thickness direction of wood section, in the wood section Four layers of temperature sensors 51 are evenly arranged in the length direction.

[0068] 2. Place a piece of eucalyptus wood section 6 in parallel on the material assembly 4, so that the thickness direction of the eucalyptus wood section is consistent with the radia...

Embodiment 2

[0076] Except that the thickness of the eucalyptus wood section is 20 mm, and one temperature sensor 51 is evenly arranged in the thickness direction of the wood section, the rest is the same as that of Embodiment 1.

Embodiment 3

[0078] Except that the absolute pressure in the wood treatment chamber cavity during ultrasonic treatment is 0.03MPa, the power of each ultrasonic transducer is 150W, the frequency is 20kHz, and the ultrasonic power applied to each square centimeter of wood section is 1.5W, the rest are consistent with the implementation Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com