Wood high-temperature high-pressure overheat steam drying method and its drying device

A technology of superheated steam, high temperature and high pressure, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of steep moisture content gradient, low equilibrium moisture content, cracking, shrinkage, etc., and achieve gentle moisture content gradient, The effect of low production cost and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

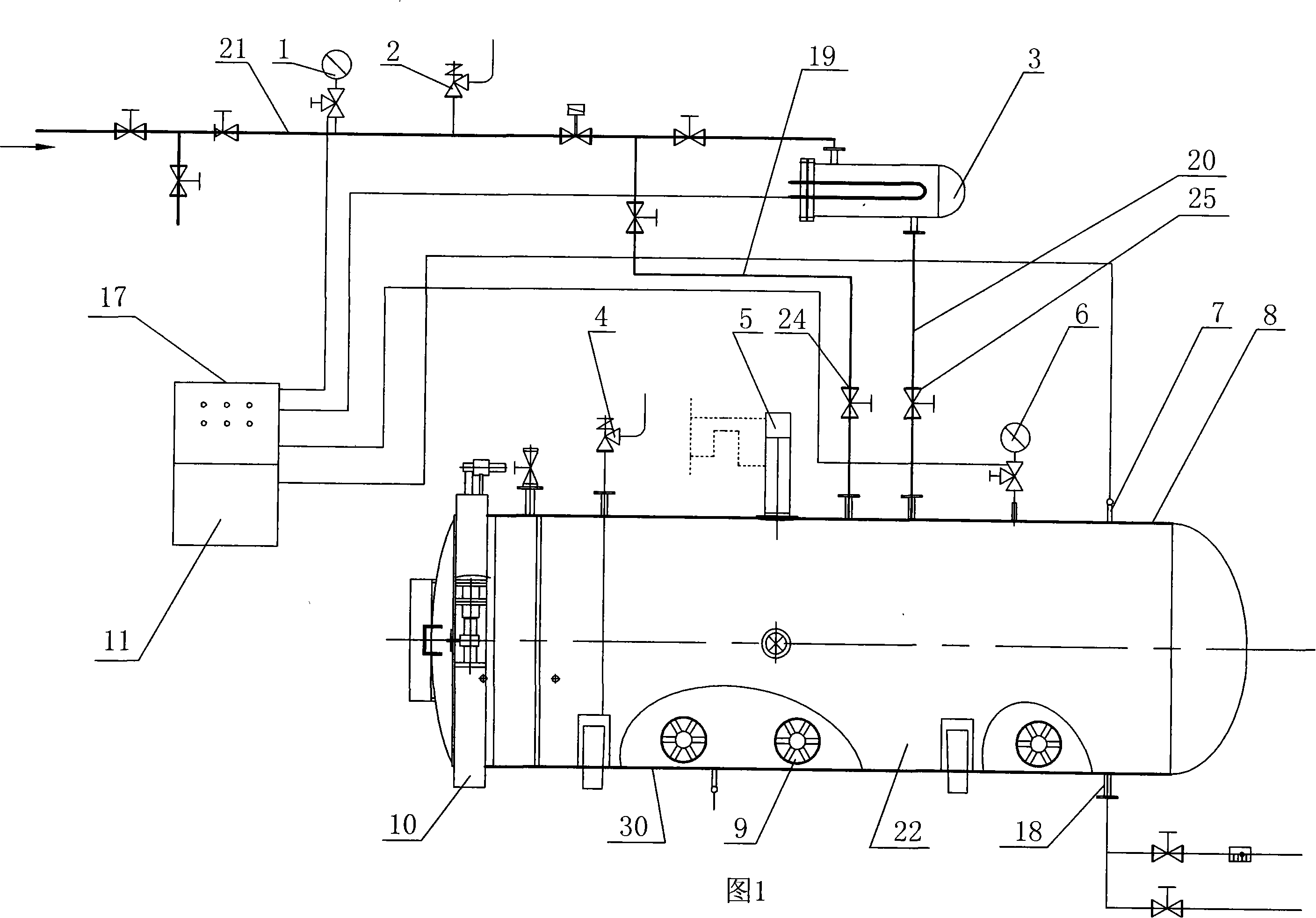

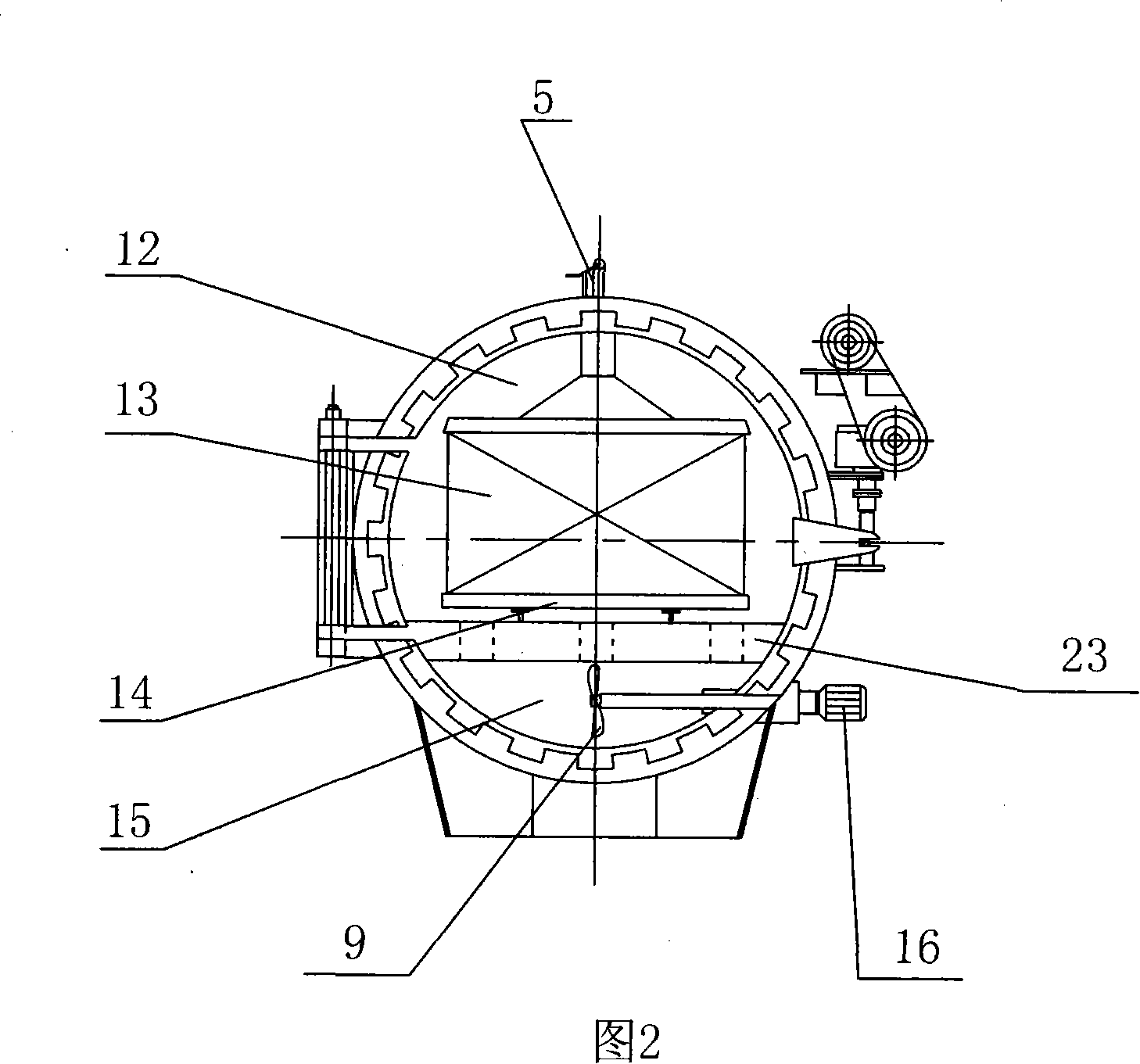

[0009] Embodiment 1: The method for drying wood with high temperature and high pressure superheated steam in this embodiment is realized according to the following steps: 1. Put the wood in a high temperature and high pressure superheated steam drying device and close the kettle door; The pressing pressure of the pressing device above the pile is 500~1000kg / m 2 3. Continue to heat the high-temperature saturated steam into superheated steam through the superheated steam generator and pass it into the kettle body of the above drying device to dry the wood; 4. Adjust the temperature of the superheated steam medium by changing the heating power of the superheated steam generator, And keep the temperature of the superheated steam medium in the kettle at 120~180℃. Fifth, adjust the saturation of the superheated steam medium by changing the saturated steam pressure input to the superheated steam generator, and keep the saturation of the superheated steam medium in the kettle at 20~80 ...

specific Embodiment approach 2

[0010] Specific embodiment 2: In this embodiment, in step 2, the pressing pressure of the pressing device above the material stack is 750kg / m 2 . The surface of the dry material is flat and free of defects such as warpage and deformation. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: In this embodiment, in step 4, the temperature of the superheated steam medium is 160°C. Good drying effect and no defects such as cracking. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com