Extraction method and extraction equipment of natural borneol

A technology of natural borneol and extraction method, applied in separation methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of only 0.7 overall yield, low production efficiency, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

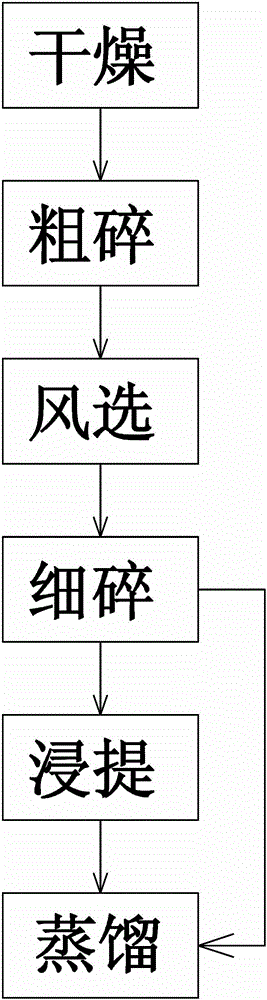

[0085] like figure 1 Among them, a kind of extracting method of natural borneol, comprises the following steps:

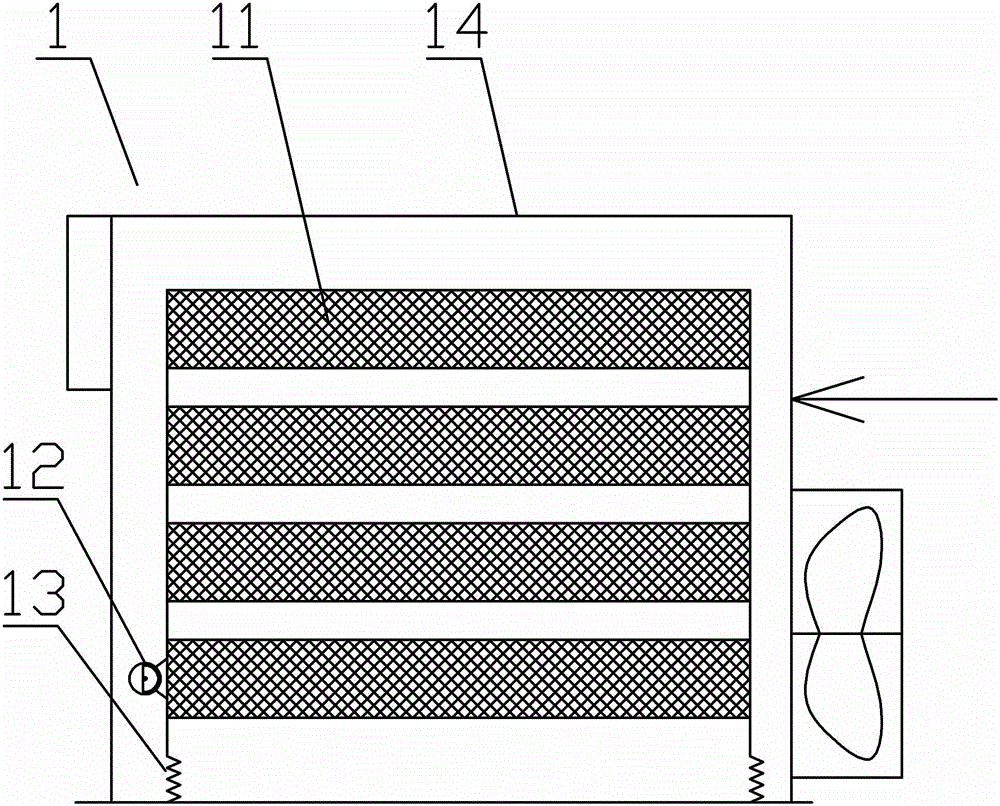

[0086] 1. Drying: air-dry the collected camphor leaves and branches; preferably, when drying, use grid-type stacking and vibration air-drying to control the moisture content of the raw materials at 10-25%. Further preferably, the moisture content of raw materials is controlled at 15-20%. Further preferred control raw material water content is about 18%. The moisture content of the collected fresh camphor tree branches and leaves is about 48-52%. The moisture content of the dried raw materials is too high, because there are more volatiles in it, which makes it difficult to purify the natural borneol in the later stage; while the moisture content is too low, there are some Natural borneol will also volatilize, reducing the yield. In the preferred solution of the present invention, the air-drying time is shortened by using grid-type stacking vibration air-drying. A...

Embodiment 2

[0094] like figure 1 Among them, another optional technological process is, a kind of extraction method of natural borneol, comprises the following steps:

[0095] One, drying, the camphor leaves and camphor branches collected are air-dried;

[0096] 2. Coarse crushing, sending the dry raw materials into the chopping device for chopping;

[0097] 3. Sorting, sending the chopped raw materials into the winnowing device to sort out branches and leaves;

[0098] Four, finely crushed, adopt different equipment finely according to the raw material of sorting, wherein branch adopts hammer mill to pulverize, and particle size crosses 20 mesh sieves; Leaves adopt the mode of chopping to finely crush; Above-mentioned steps are identical with embodiment 1.

[0099] Five, distillation condensation,

[0100]Different from Example 1, an extraction process is added in this example. Extract the semi-finished branch raw material and semi-finished leaf raw material with absolute ethanol, fi...

Embodiment 3

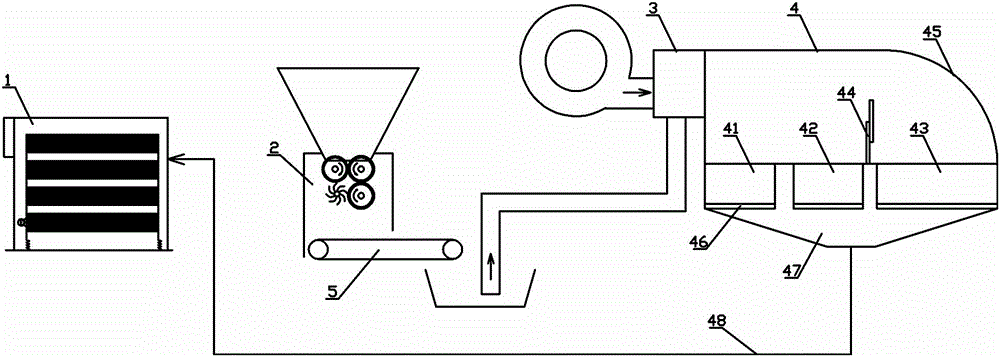

[0108] An extraction device for natural borneol, comprising a pretreatment device, the pretreatment device includes a chopping device, the pretreatment device is connected to the winnowing device 4 through the wind blowing device 3, and at least two discharge ports are arranged in the winnowing device 4 , wherein the branch discharge port 41 is connected with the hammer mill, and the leaf discharge port 43 is connected with the leaf chopping device 6; the hammer mill is an equipment in the prior art, not shown in the figure.

[0109] The hammer mill and the leaf chopping device 6 are respectively connected with the distillation device through a conveying device.

[0110] Or the hammer mill and the leaf chopping device 6 are respectively connected to the extraction device through the conveying device, the extraction device is connected to the filter device, the filter device is connected to the rotary evaporation device, and the rotary evaporation device is connected to the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com