Far infrared unit for dewatering vegetable

A vegetable dehydration and far-infrared technology, applied in the direction of dehydration preservation of fruits/vegetables, food processing, heating to dry solid materials, etc., can solve problems such as difficult to use in actual production, large heat loss, troublesome operation, etc., to achieve good quality, Fast drying and fast rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

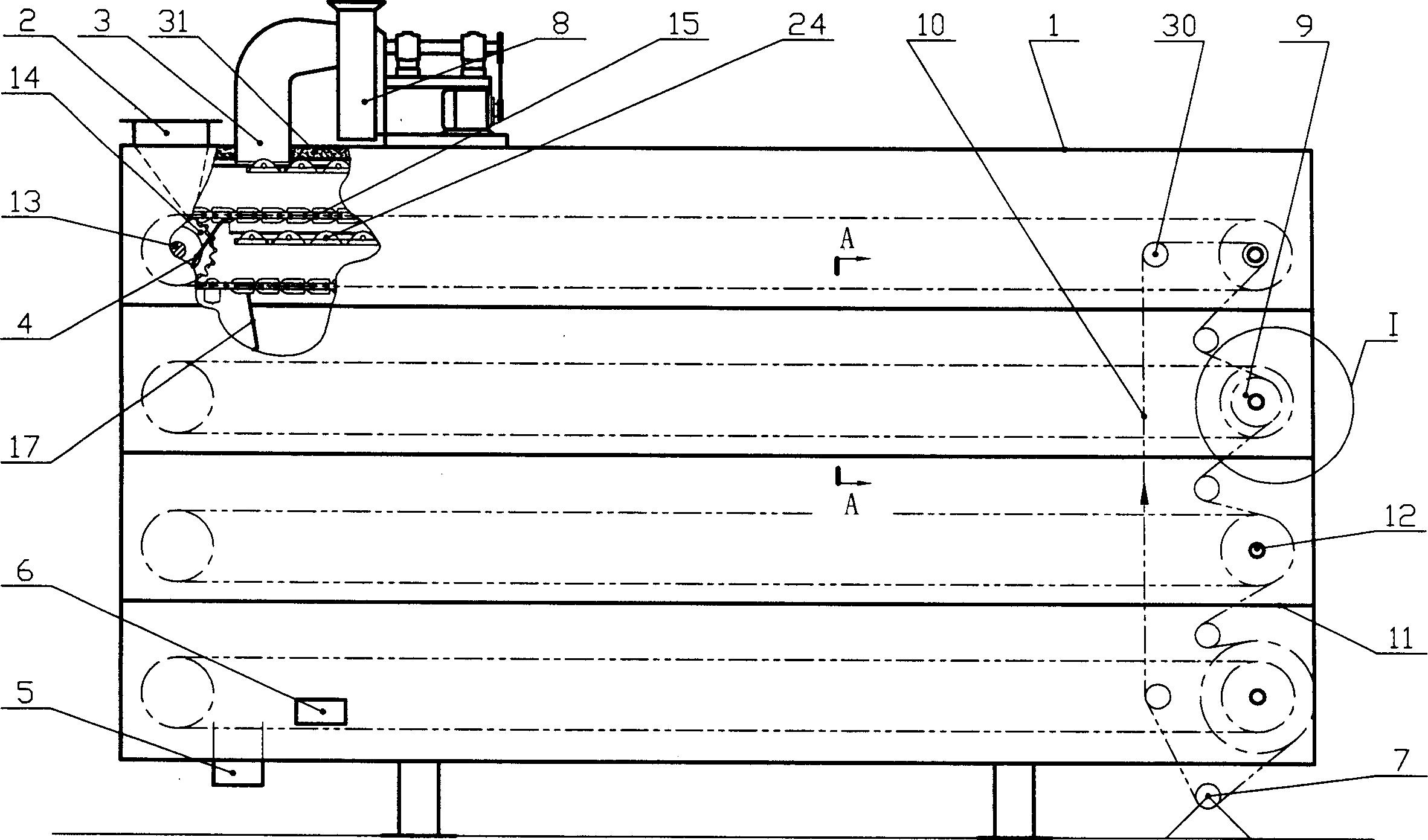

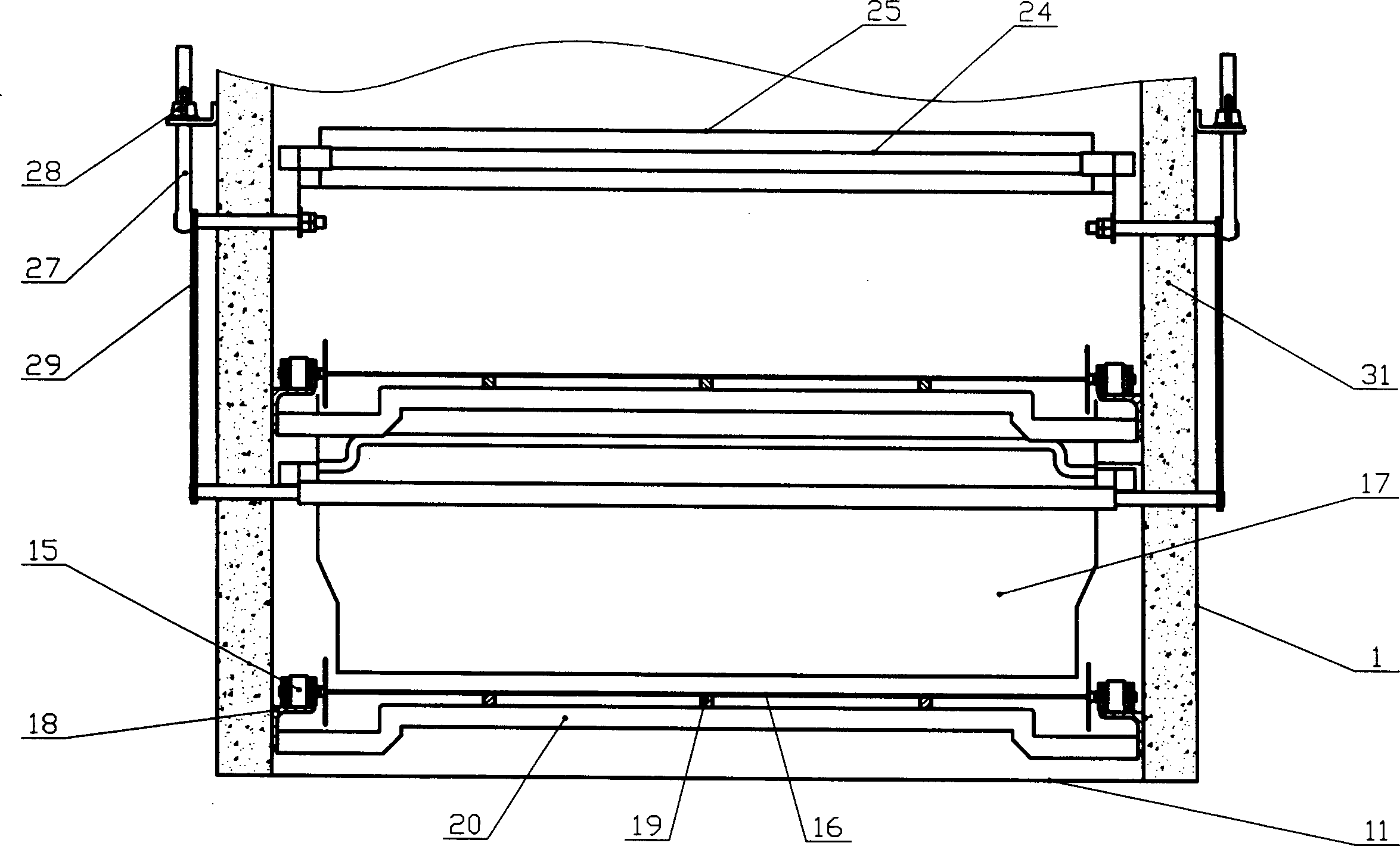

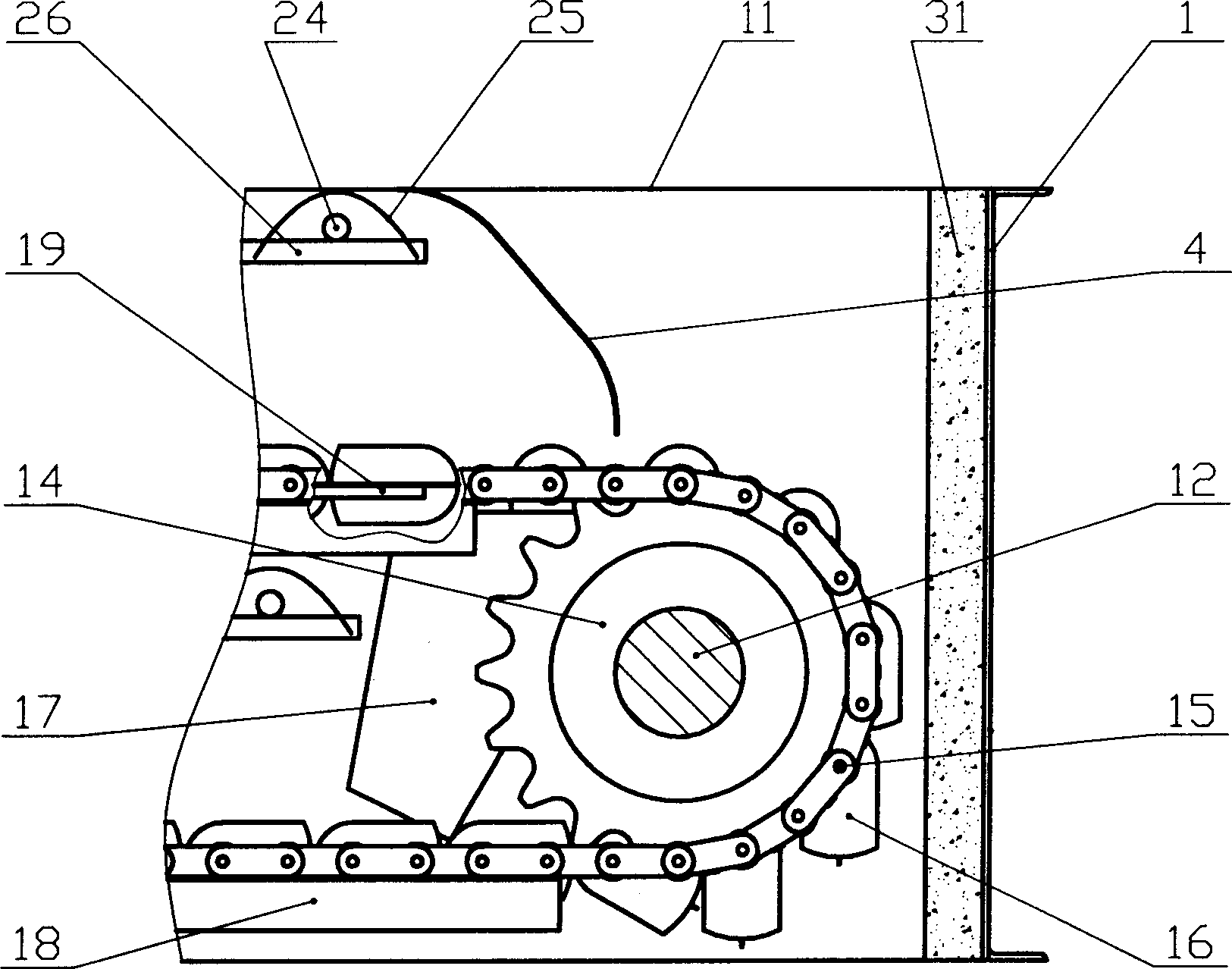

[0021] 1. Box body 2, material inlet 3, air inlet 4, deflector 5, outlet 6, air inlet 7, deceleration motor 8, fan 9, transmission sprocket 10, transmission chain 11, partition 12, drive Shaft 13, driven shaft 14, conveying sprocket 15, conveying chain 16, conveying chain plate 17, guide groove 18, chain guide rail 19, chain plate guide rail 20, bracket 21, pin shaft 22, connecting pipe 23, baffle plate 24. Radiation element 25, reflection cover 26, radiation frame 27, tie rod 28, nut 29, connecting rod 30, tensioning wheel 31, insulation layer 32, bottom plate

[0022] exist Figure 1~5In the shown embodiment: the box body wall of the box body 1 is provided with an insulating layer 31, its top is provided with a feed inlet 2 and an air induction port 3 sealedly connected with the fan 8, its bottom is provided with a discharge port 5, and the side The lower part of the wall is provided with an air inlet 6, and the inner space of the box body 1 is divided into multiple layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com