Rubber master batch continuous manufacturing method and rubber master batch prepared thereby

A technology of rubber masterbatch and manufacturing method, which is applied in the field of rubber, can solve the problems of long process, slow coagulation and drying speed, high energy consumption, etc., and achieve the effect of strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

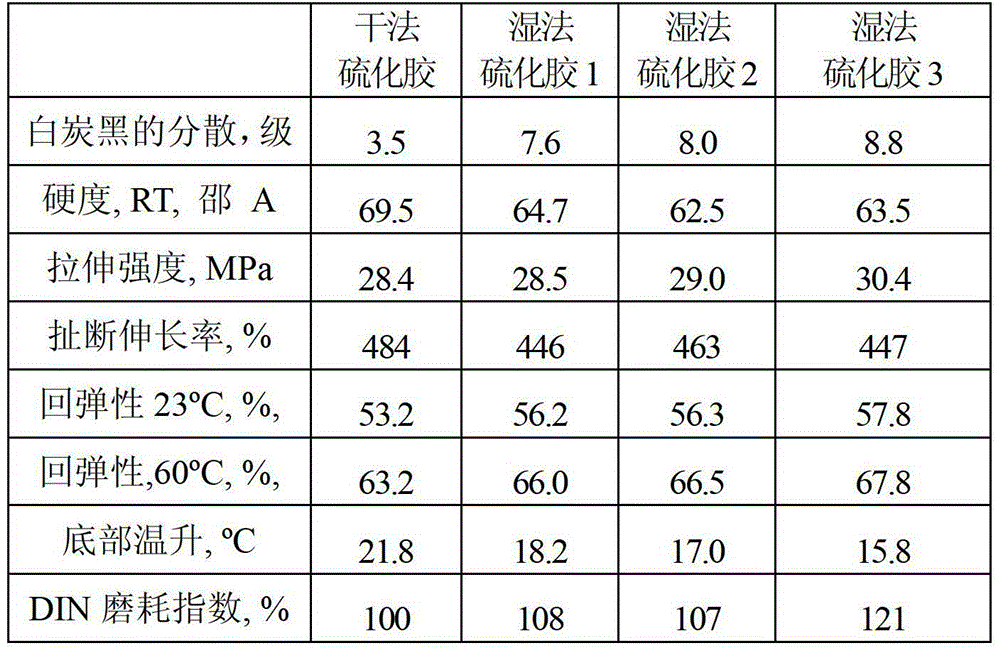

Embodiment 1

[0102] Add 56 parts of white carbon black, 5.6 parts of silane coupling agent Si69, and 3.5 parts of zinc oxide to 100 parts of 12% cis-polyisoprene in n-hexane solution, and its rubber / white carbon black / Si69 / n-hexane mixture After initial mixing with a blade mixer, the mixture is sprayed into a multi-elbow pipe through a nozzle to make the mixture collide with the pipe wall in the pipe to increase the dispersion of the filler. Finally, the mixture is continuously added to the grinder for fine dispersion to obtain a finely dispersed mixture, and then the mixture is continuously injected into the agglomerator through two inlets of the cylinder-cone agglomerator with four inlets under a pressure of 30 MPa, and at the same time Continuously inject nitrogen at a temperature of about 180°C from the other two inlets, and then continuously spray the resulting mixture into a drier filled with nitrogen at about 150°C. / Volatilize in the micro-droplets expanded by n-hexane to form des...

Embodiment 2

[0104] Add 56 parts of white carbon black, 5.6 parts of silane coupling agent Si69, and 3.5 parts of zinc oxide to 100 parts of 12% cis-polyisoprene in n-hexane solution, and its rubber / white carbon black / Si69 / n-hexane mixture After initial mixing with a blade mixer, the mixture is sprayed into a multi-elbow pipe through a nozzle to make the mixture collide with the pipe wall in the pipe to increase the dispersion of the filler. Then the mixture is continuously added to the grinder for fine dispersion to obtain the fine dispersion mixture, and then the mixture is continuously injected into the agglomerator through two inlets of the barrel-cone agglomerator with four inlets under a pressure of 30 MPa, and at the same time Water at a temperature of about 95°C was continuously injected from the other two inlets to coagulate the mixture. The coagulated and desolvated colloidal particles were filtered and dried in a vacuum dryer at a vacuum degree of -0.08 MPa for 20 minutes, and t...

Embodiment 3

[0106]Add 56 parts of white carbon black, 5.6 parts of silane coupling agent Si69, and 3.5 parts of zinc oxide to 100 parts of 12% cis-polyisoprene in n-hexane solution, and its rubber / white carbon black / Si69 / n-hexane mixture After initial mixing with a blade mixer, the mixture is sprayed into a multi-elbow pipe through a nozzle to make the mixture collide with the pipe wall in the pipe to increase the dispersion of the filler. Finally, the mixture is continuously added to the grinder for fine dispersion to obtain a finely dispersed mixture, and then the mixture is continuously injected into the agglomerator through two inlets of the barrel-cone agglomerator with four inlets under a pressure of 30 MPa, and at the same time Water at a temperature of about 95°C was continuously injected from the other two inlets to coagulate the mixture. The coagulated and desolvated rubber particles were filtered and then dried in a single-screw extruder for 3 minutes to obtain masterbatch 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com