Efficient and energy saving ground flare gas system

A ground torch, high-efficiency and energy-saving technology, applied in the combustion of block fuel and gaseous fuel, the combustion of liquid fuel and gaseous fuel, the combustion of gaseous fuel and powder fuel, etc., can solve the problem of high investment and complex structure, etc. problem, to achieve the effect of less investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

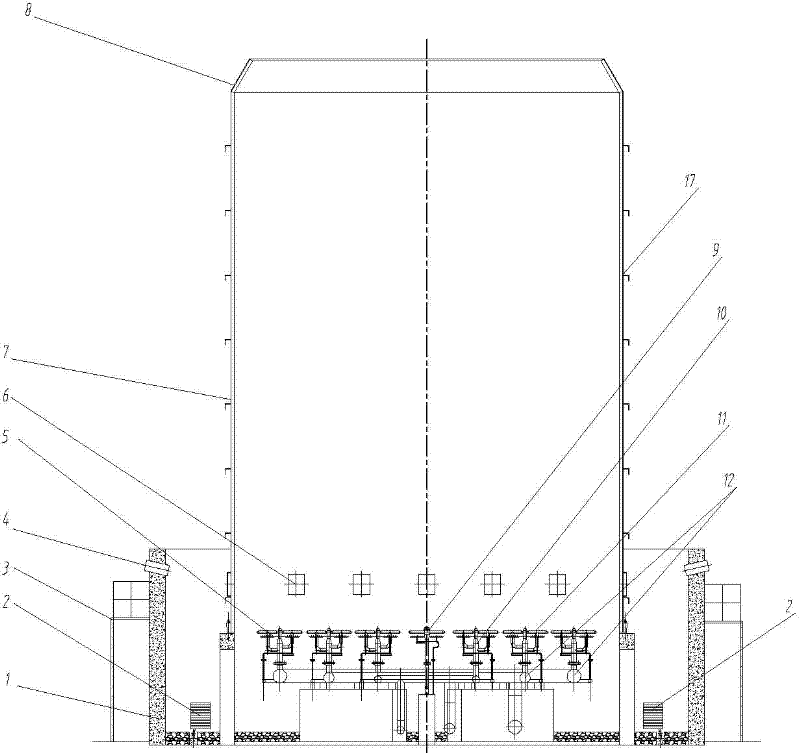

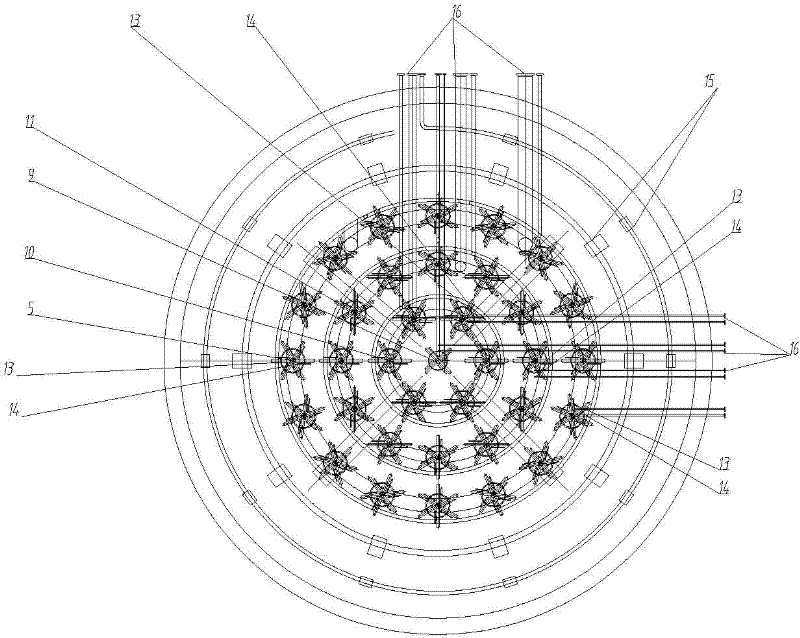

[0017] Such as Figure 1-4 shown.

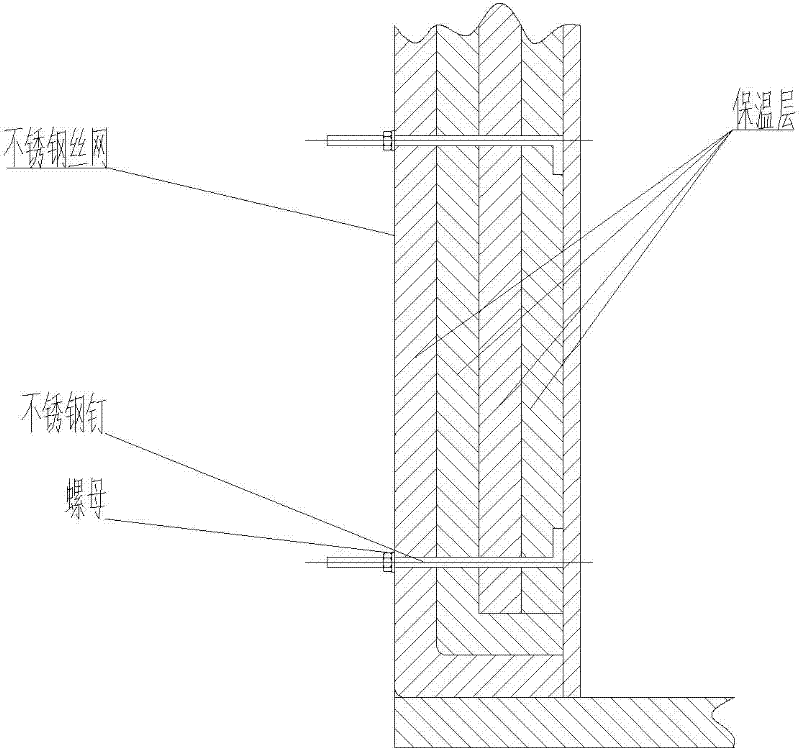

[0018] A kind of high-efficiency and energy-saving ground flare gas system, it comprises flare shell 7, windproof noise reduction screen 1, such as figure 1 As shown, the inner surface of the torch barrel 7 is provided with an insulating layer 17 (such as figure 2 shown), the thickness of the insulation layer 17 is 50-200mm, the inner two-layer overlap should be staggered but not overlapped, and the outer two-layer overlap should overlap 80-200mm, and the thermal insulation material is refractory ceramic fiber. Heat-resistant stainless steel wire mesh with a wire diameter of ?1-5mm, overlapping 80-200mm at the overlap. The torch cylinder 7 is located in the windproof and noise-absorbing screen 1, the lower part of the torch cylinder 7 is provided with an air inlet, the cylinder above the air inlet is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com