Structure for preventing water at back of tunnel lining from longitudinally streaming

A longitudinal and lining technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of structural damage and rising water pressure of tunnel lining, and achieve the effect of reducing maintenance costs, increasing diameter, and structural safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment : Embodiment and 1 ,, and 。 specific Embodiment approach

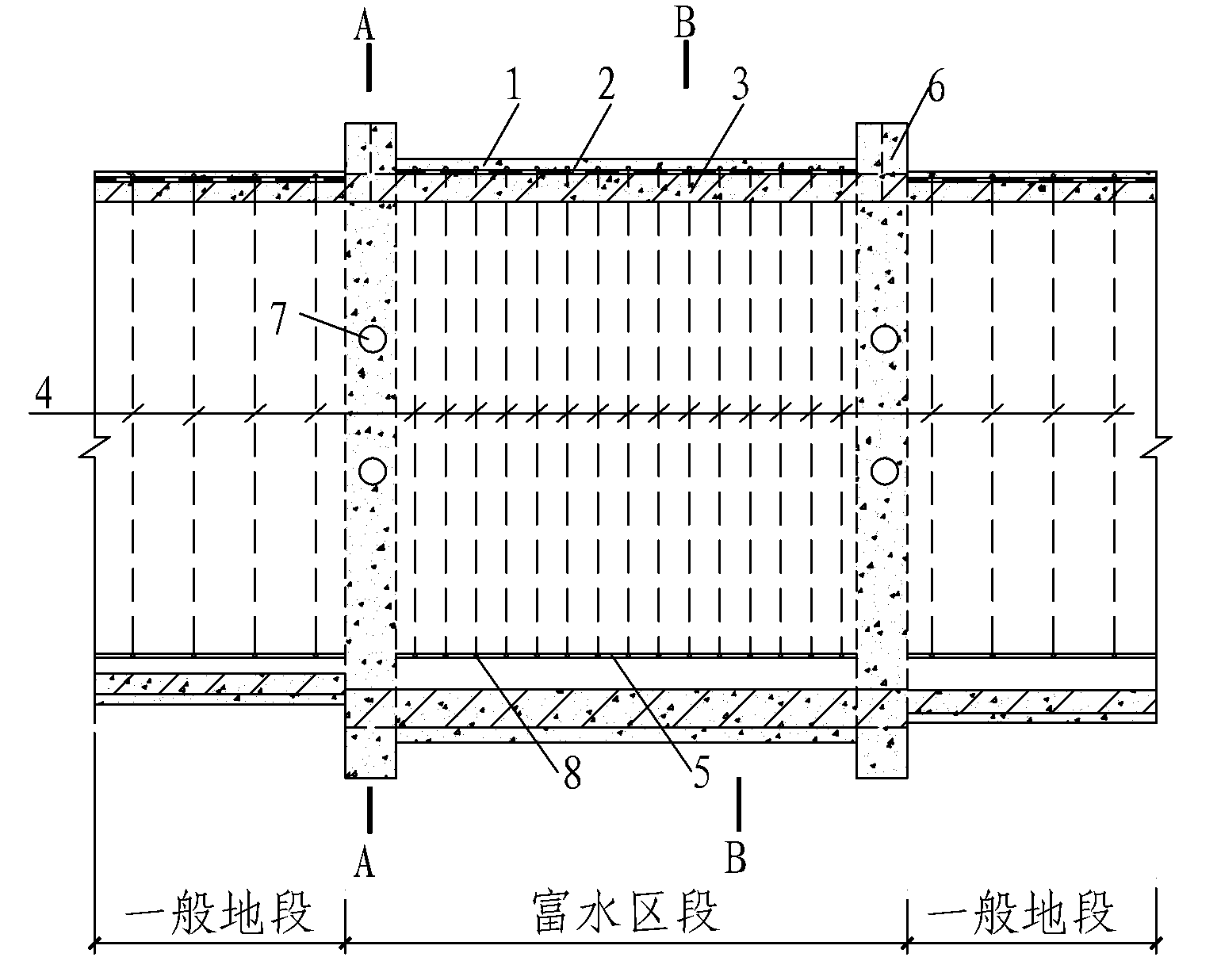

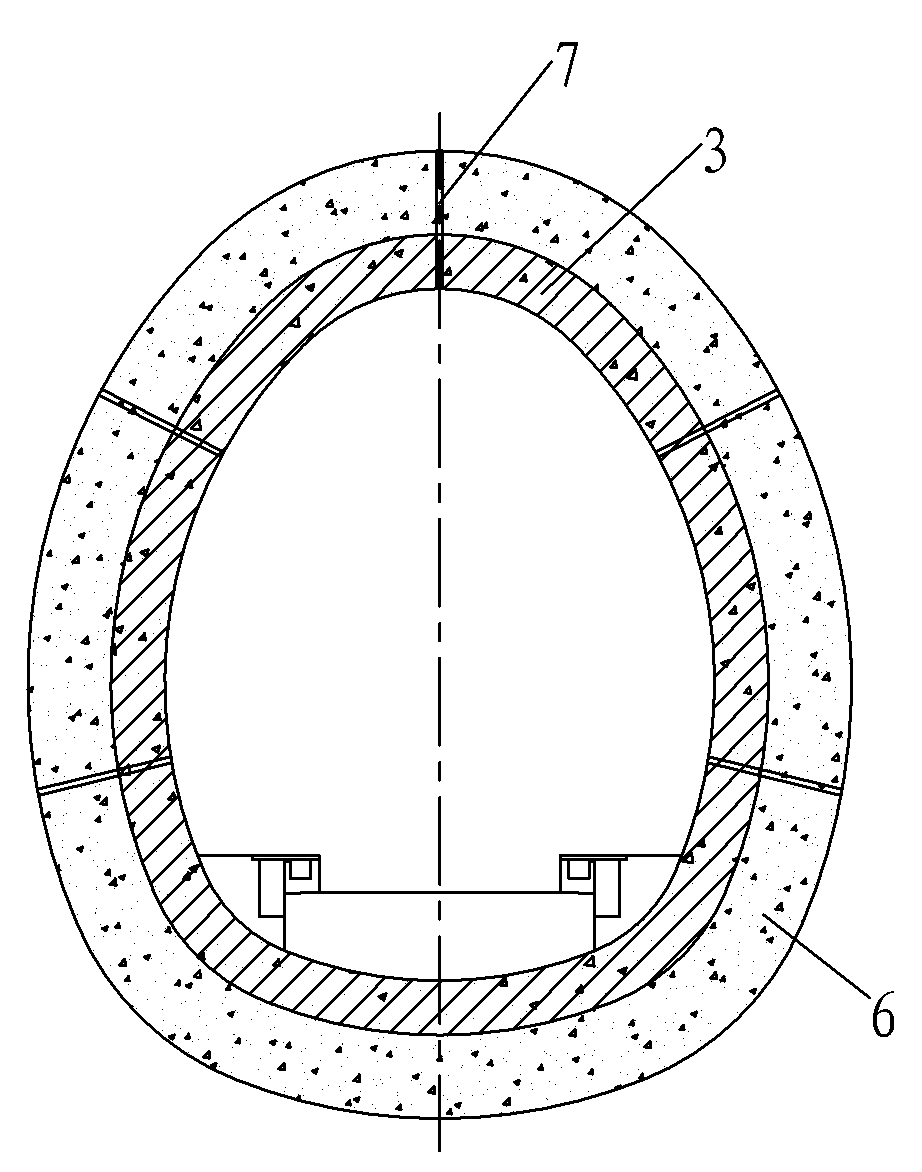

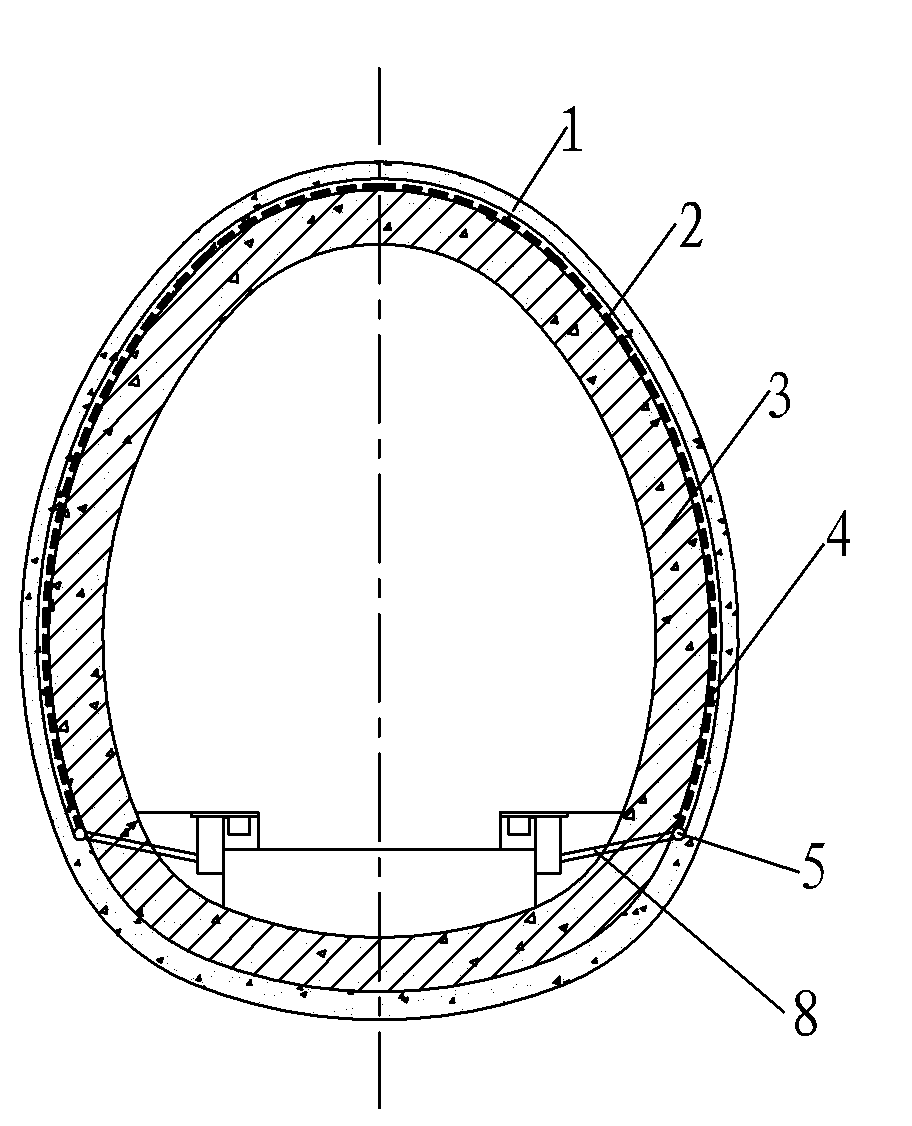

[0026] 1) The water blocking ring 6 is located on the outer edge of the secondary lining 3, and its general size is 1×1m (width×height). The size of the water blocking ring can be determined according to the actual situation on site, and the waterproof board between different water-rich sections can be cut off 2. The vertical drainage pipe 5 is poured integrally with the secondary lining 3 to form an integral body to prevent the longitudinal flow of underground water.

[0027] 2) A certain number of radial grouting pipes 7 are reserved along the radial direction of the water blocking ring 6. The diameter, material and quantity of the pre-embedded radial grouting pipes can be determined according to the actual geological conditions, but generally should not be less than 5 , using the radial grouting pipe 7 to backfill the gap between the water blocking ring 7 and the surrounding rock, and at the same time, grouting a certain range of surrounding rock behind the water blocking ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com