Electric power overhaul equipment lifting device

A lifting device and power maintenance technology, applied in the direction of lifting equipment safety device, lifting device, lifting frame, etc., can solve the problems of large occupied space, fixed equipment volume, inability to shrink, etc., to achieve convenient storage and movement, safe and reliable structure , the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

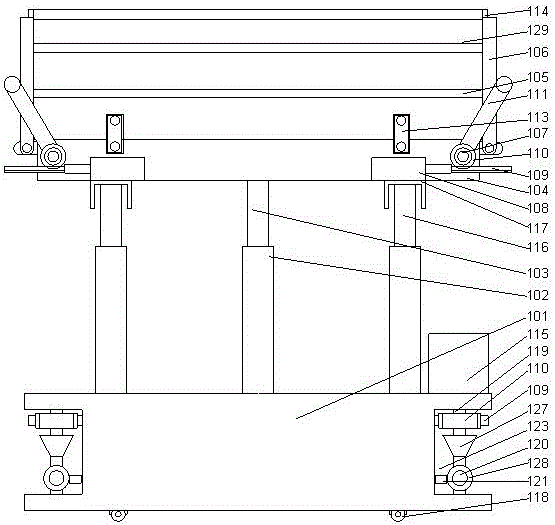

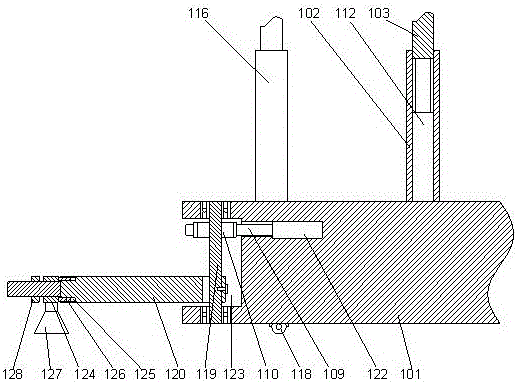

[0027] Such as figure 1 , 2 As shown, a lifting device for electric power maintenance equipment includes a base 101 and a hydraulic lifting assembly arranged above the base, a lifting platform 104 is arranged above the base, and the lifting platform is close to two mutually parallel edge parts A fixed frame 105 is respectively arranged above, and a movable frame 106 is arranged on the other two mutually parallel side walls of the lifting platform, and the moving frame is hinged on the side wall of the lifting platform. Compressed airbags are respectively arranged on the inner end surfaces of the fixed frame and the movable frame;

[0028] Two rotating shafts 107 are arranged on the side wall of the lifting platform, and the moving frames are respectively sleeved on the rotating shafts, and a first hydraulic cylinder 108 is arranged on the lower end surface of the lifting platform. A rack 109 is provided on the telescopic rod of the first hydraulic cylinder, a gear 110 is pro...

Embodiment 2

[0034]This embodiment is based on Embodiment 1. In this embodiment, in order to make the lifting platform more stable, preferably, a channel steel is provided on the lower end surface of the lifting platform, and a second Three hydraulic cylinders 116, the telescopic rod of the third hydraulic cylinder can be clamped in the channel steel, and the third hydraulic cylinder is connected with the controller through a line. The third hydraulic cylinder can be arranged on both sides of the hydraulic lifting assembly to make the overall structure more stable. At the same time, an inclined support reinforcement structure can be arranged outside the third hydraulic cylinder to facilitate the stability of the third hydraulic cylinder.

[0035] In order to facilitate the movement of the whole structure, in this embodiment, preferably, a roller 118 is provided under the base.

[0036] In order to increase the stress-bearing area of the base and improve the stability of the overall struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com