Compact spray cooling heat exchanger

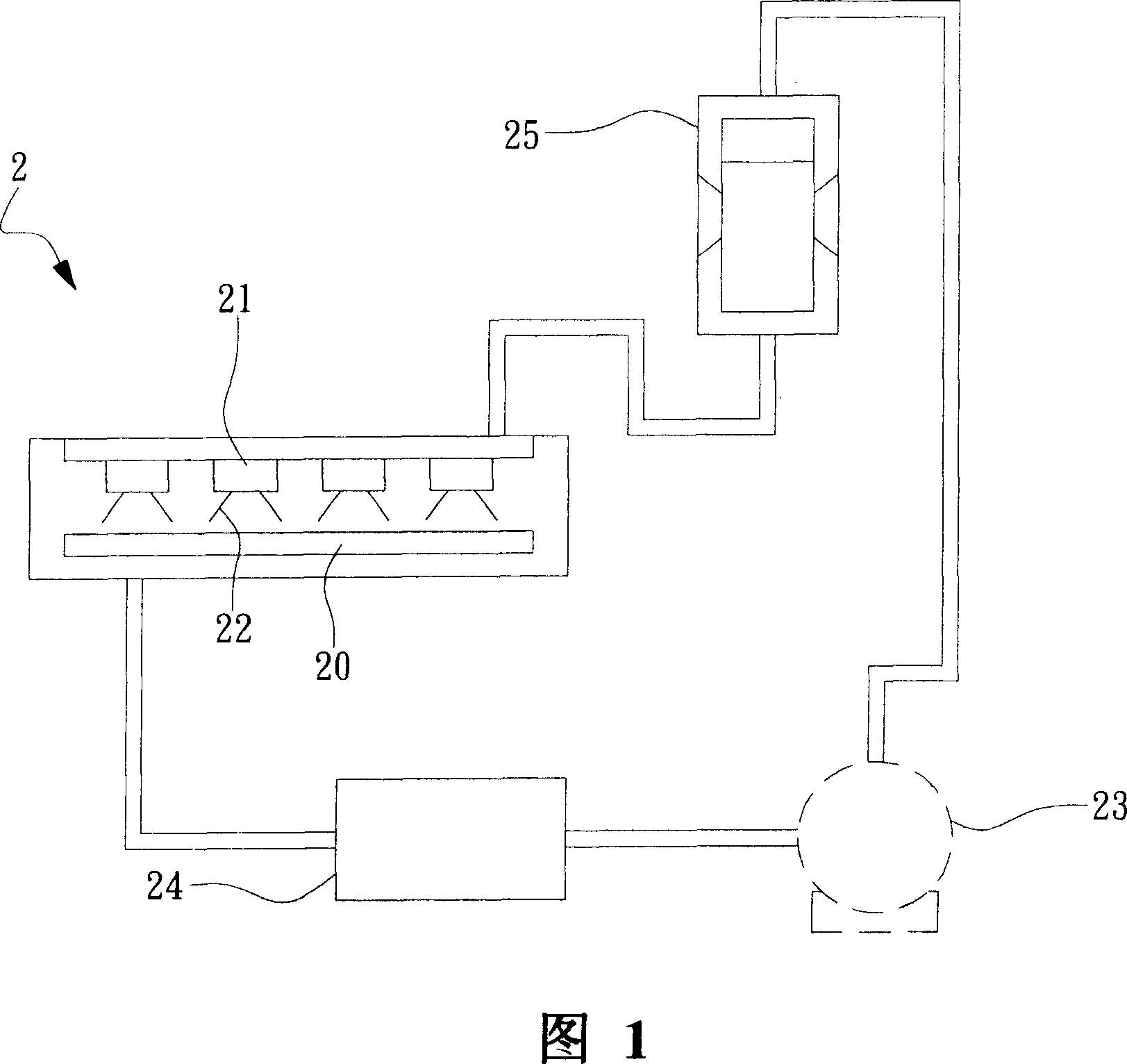

A spray cooling and heat dissipation device technology, applied in the direction of cooling/ventilation/heating transformation, refrigerators, refrigeration components, etc., can solve the problems of increasing the size and cost of the heat dissipation system, high power supply, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable your examiner to have a further understanding of the features, purpose and functions of the present invention, the detailed structure and design ideas of the present invention will be described below so that the examiner can understand the characteristics of the present invention and describe in detail as follows:

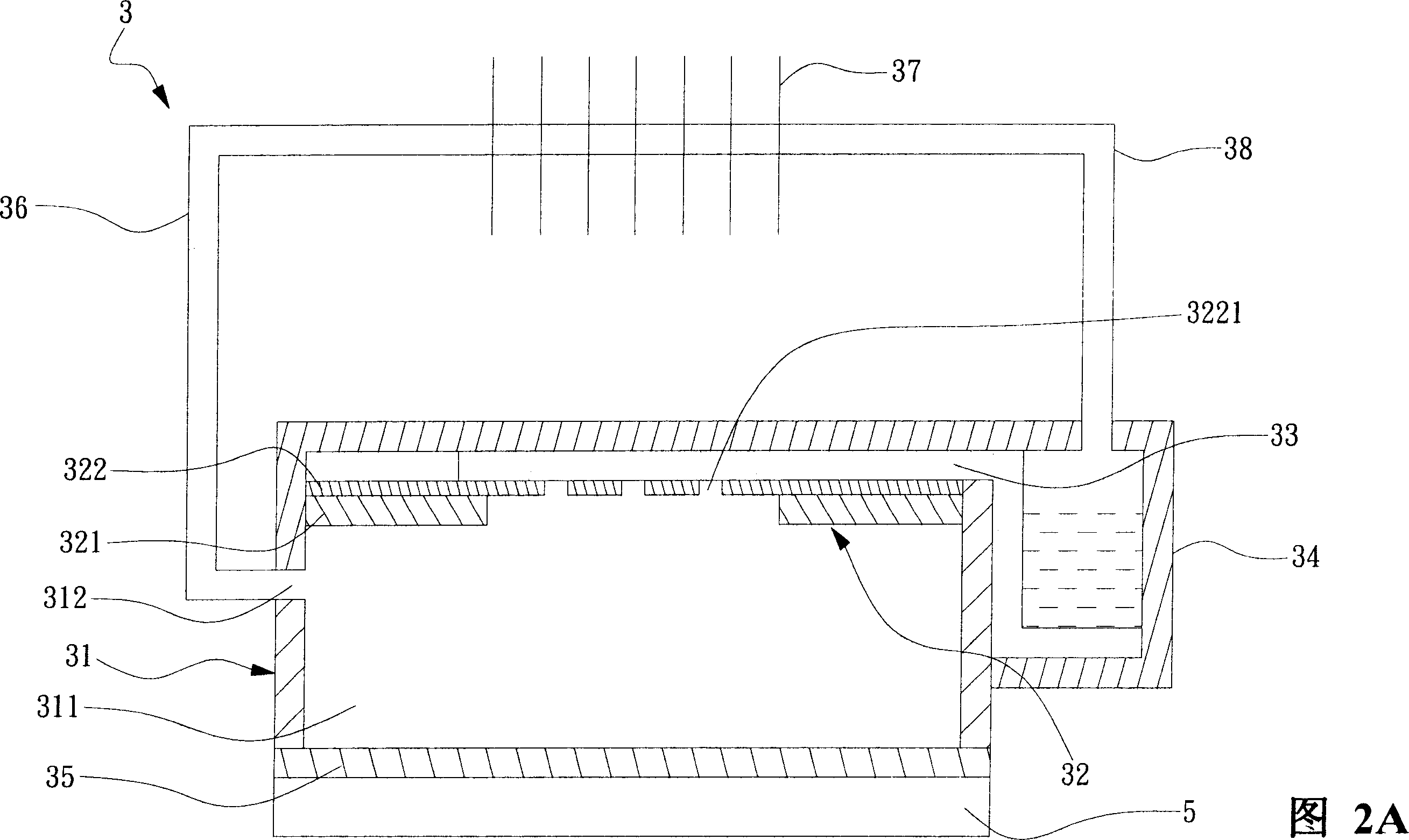

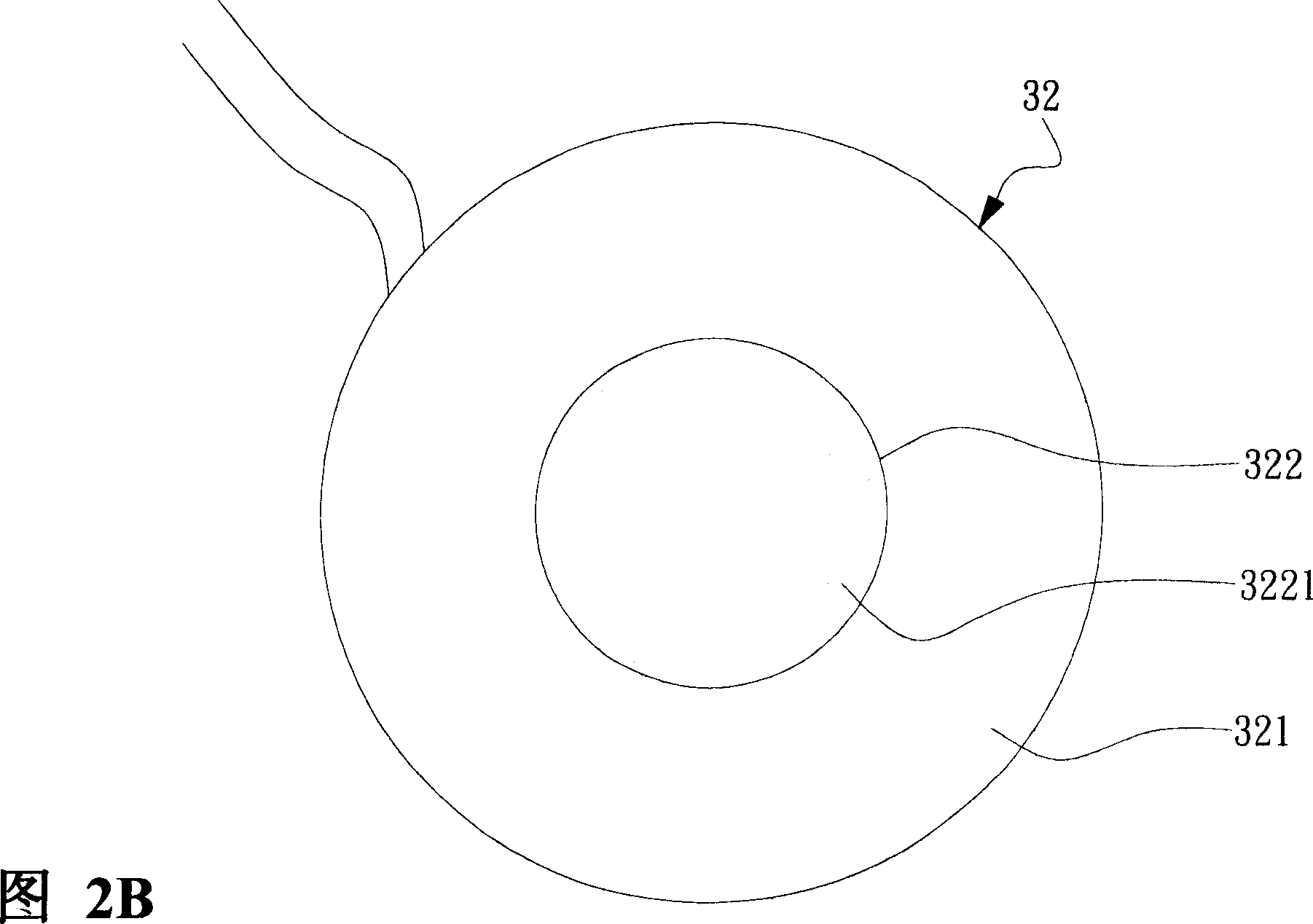

[0045] Please refer to FIG. 2A , which is a schematic view of the first preferred embodiment of the compact spray cooling heat dissipation device of the present invention. The spray cooling device 3 includes a spray cabin 31 , a liquid storage tank 34 , an atomizer 32 and a liquid delivery body 33 . The spray cabin 31 has a certain volume and is hollow inside to form a coolant spray space 311 . There is a heat-absorbing plate 35 made of a material with high thermal conductivity (such as copper or aluminum) at the bottom of the spray cabin 31; Please refer to FIG. 3 , which is a schematic diagram of a preferred embodiment of the heat abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com