Anti-explosion fire reconnaissance firefighting robot and working method

A fire-fighting robot and fire-fighting technology, applied in the field of robots, can solve problems such as slippage, failure to meet the needs of reconnaissance and fire-fighting, and insufficient protection level of fire-fighting reconnaissance and fire-fighting robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

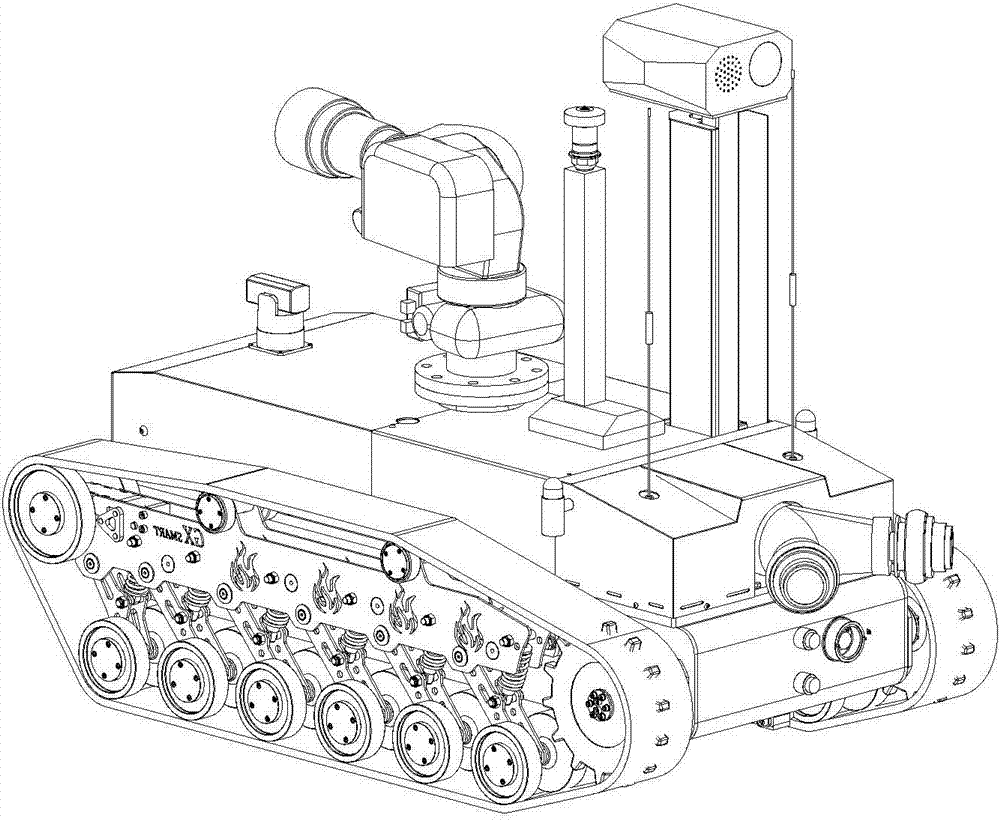

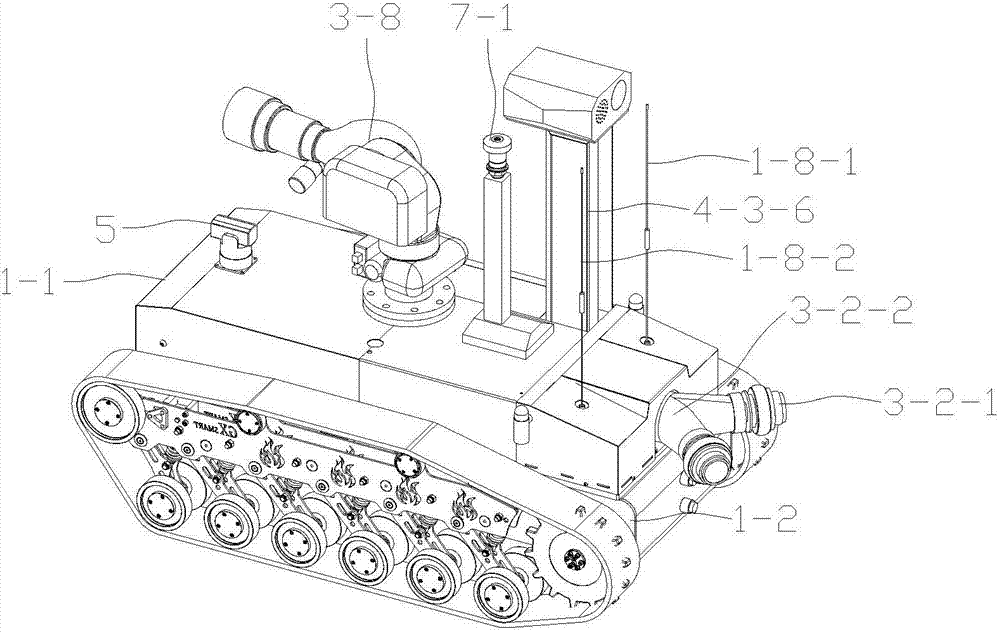

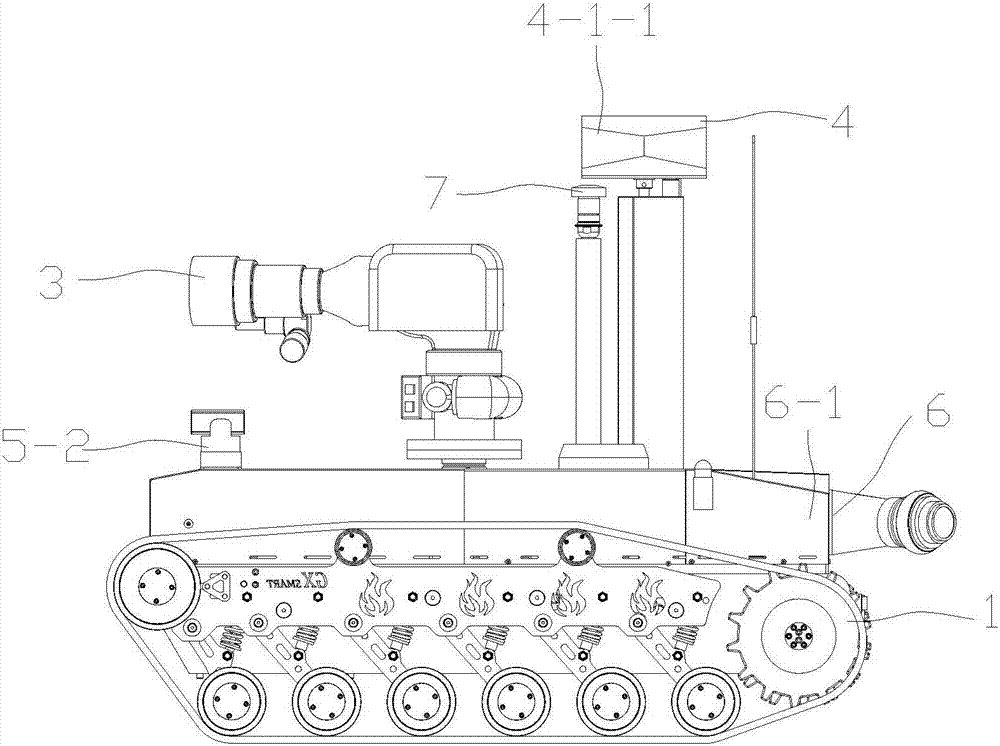

[0093] Such as Figure 1-17 As shown, an explosion-proof fire-fighting reconnaissance and fire-extinguishing robot includes a mobile chassis 1 of an explosion-proof fire-fighting reconnaissance fire-fighting robot, a manipulation control box 2, an explosion-proof fire water cannon 3, an explosion-proof reconnaissance component 4, an explosion-proof road condition camera component 5, and an explosion-proof fire hose shedding component 6. Explosion-proof self-sprinkling cooling assembly 7, the mobile chassis 1 of the explosion-proof fire-fighting reconnaissance and fire-extinguishing robot is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com