Low pressure casting wheel cooling technology

A technology, water mist cooling technology, applied in the field of casting cooling technology, can solve the problems of easy cracking of the mold, short life, easy corrosion of the mold, low cooling intensity, etc., to reduce the pinhole scrap rate, rework rate, and shrinkage defect probability Small, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

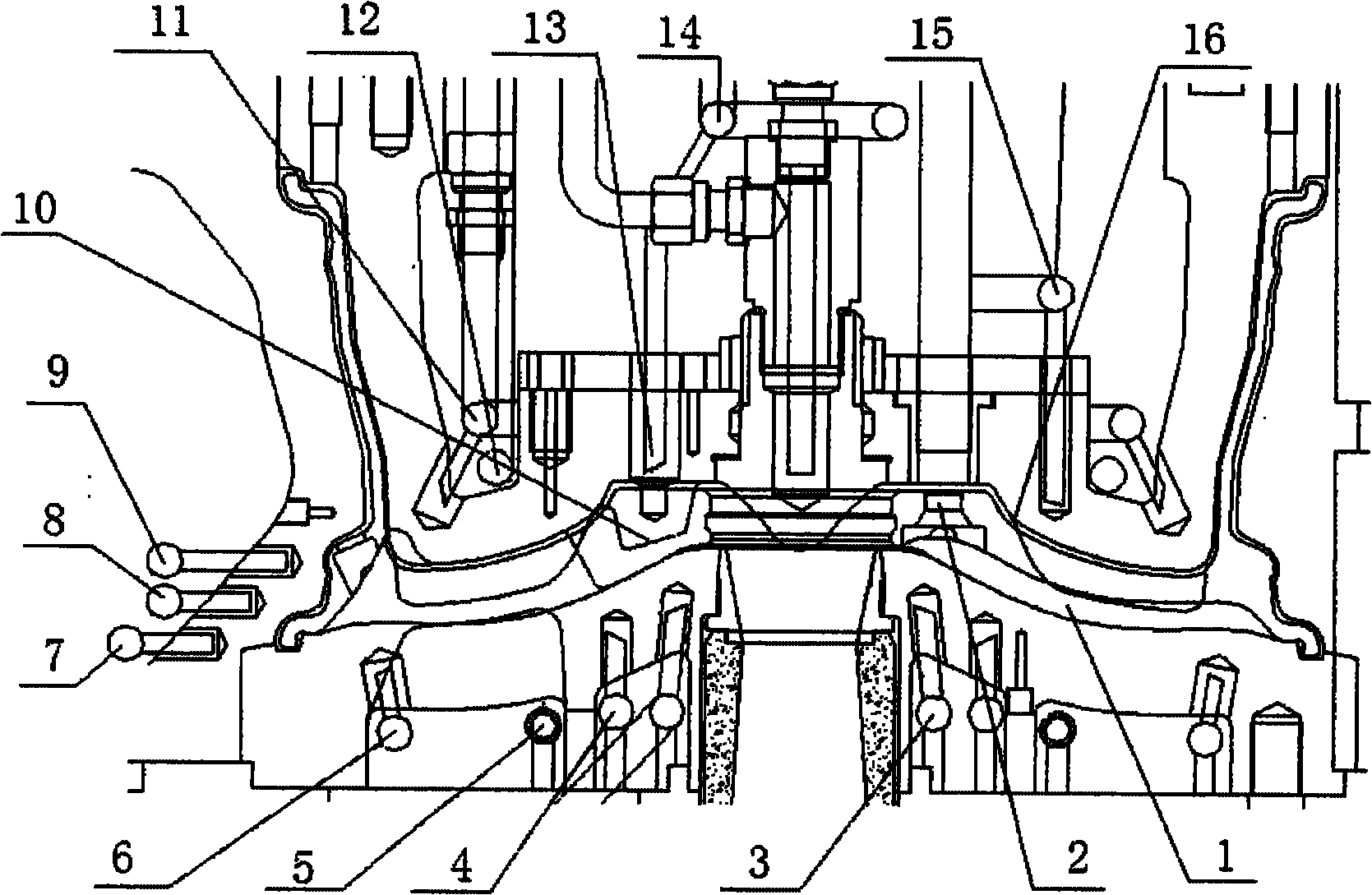

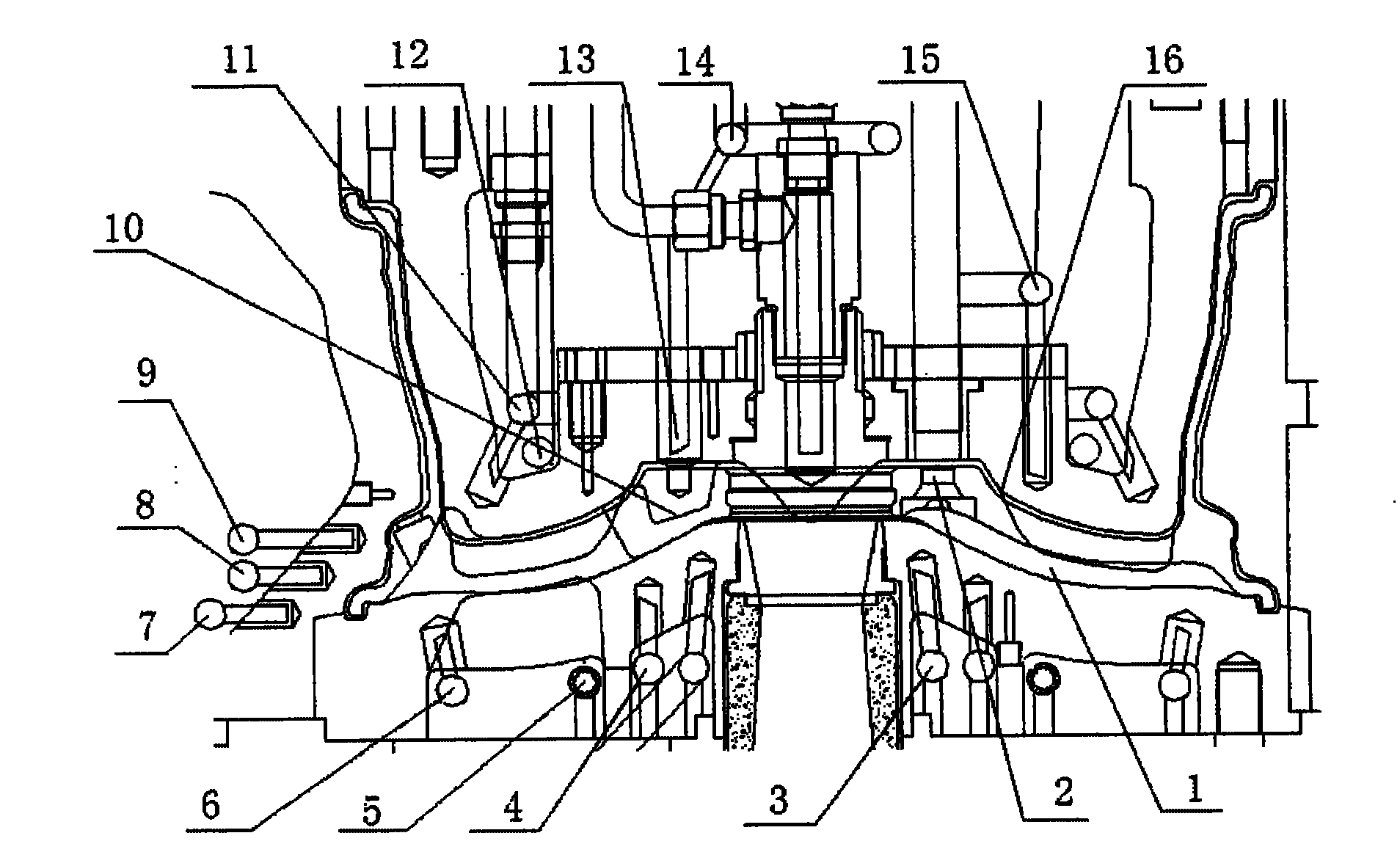

[0017] Use water mist cooling device to cool the mold, including bottom mold riser wind 3, bottom mold middle circle wind 4 upper mold center wind 14, upper mold five-hole wind 13, upper mold middle circle wind 15, side mold wind 7 use water mist Cooling, the rest of the bottom mold with a small amount of ventilation is air-cooled from 470°C to 470°C within 40 seconds. Cooling to 430°C, the mold temperature is reduced by 40°C.

[0018] The water temperature of the cooling water tank is 50°C; the ratio of water and air is 1:800.

Embodiment 2

[0020] Use water mist cooling device to cool the mold, including bottom mold center air 4, upper mold center air 14, upper mold five-hole air 13, upper mold middle circle air 15, use water mist to cool, and other bottom molds with small ventilation Large circle wind 5, bottom mold outer circle wind 6, upper mold large circle wind 12, upper mold outer circle wind 11 air ducts use air cooling, side mold wind 7, 8 use water cooling, so that the mold can be cooled from 480 ℃ within 50 seconds To 420°C, the mold temperature is reduced by 60°C.

[0021] The water temperature of the cooling water tank is 25°C; the ratio of water and air is 1:700.

Embodiment 3

[0023] Use a water mist cooling device to cool the mold, including the bottom mold middle circle air 4, the upper mold five-hole air 13, the upper mold middle circle air 15 are cooled by water mist, and the rest of the bottom mold with small ventilation volume big circle wind 5, bottom mold The outer ring air of the mold 6, the large ring air of the upper mold 12, the air duct of the outer ring of the upper mold 11 use air cooling, the riser air of the bottom mold 3, the center air of the upper mold 14, and the side mold air 7, 8, 9 use water cooling, so that the mold Cooling from 490°C to 410°C in 60 seconds, the mold temperature drops by about 80°C.

[0024] The water temperature of the cooling water tank is 1°C; the ratio of water and air is 1:600.

[0025] Drill 3 holes according to the width of the mold spokes for water cooling.

[0026] The overall mechanical properties of the products obtained in the above three embodiments are all higher than those obtained by simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com