Apparatus and method for cleaning soiled surfaces with...

a technology for cleaning surfaces and apparatus, applied in the direction of carpet cleaners, vehicle cleaning, cleaning using liquids, etc., can solve the problems of affecting the economy of operation, requiring more force (and fuel) to propel the aircraft, and dirty aircraft also present an aesthetics and public image problem, so as to achieve the effect of effective cleaning soiled surfaces, avoiding appreciable run-off or remaining residue, and speeding up aircraft cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Applicant's invention includes an apparatus (hereinafter referred to as a “cleaning system” or simply “system”) which operates through the forced application of cleaning solutions onto surfaces which are to be cleaned and, (optionally) after agitation of the cleaning solutions over the soiled surface, recovery of the cleaning solution / contaminant mixture through action of squeegee-like collection means in association with vacuum or suction orifices.

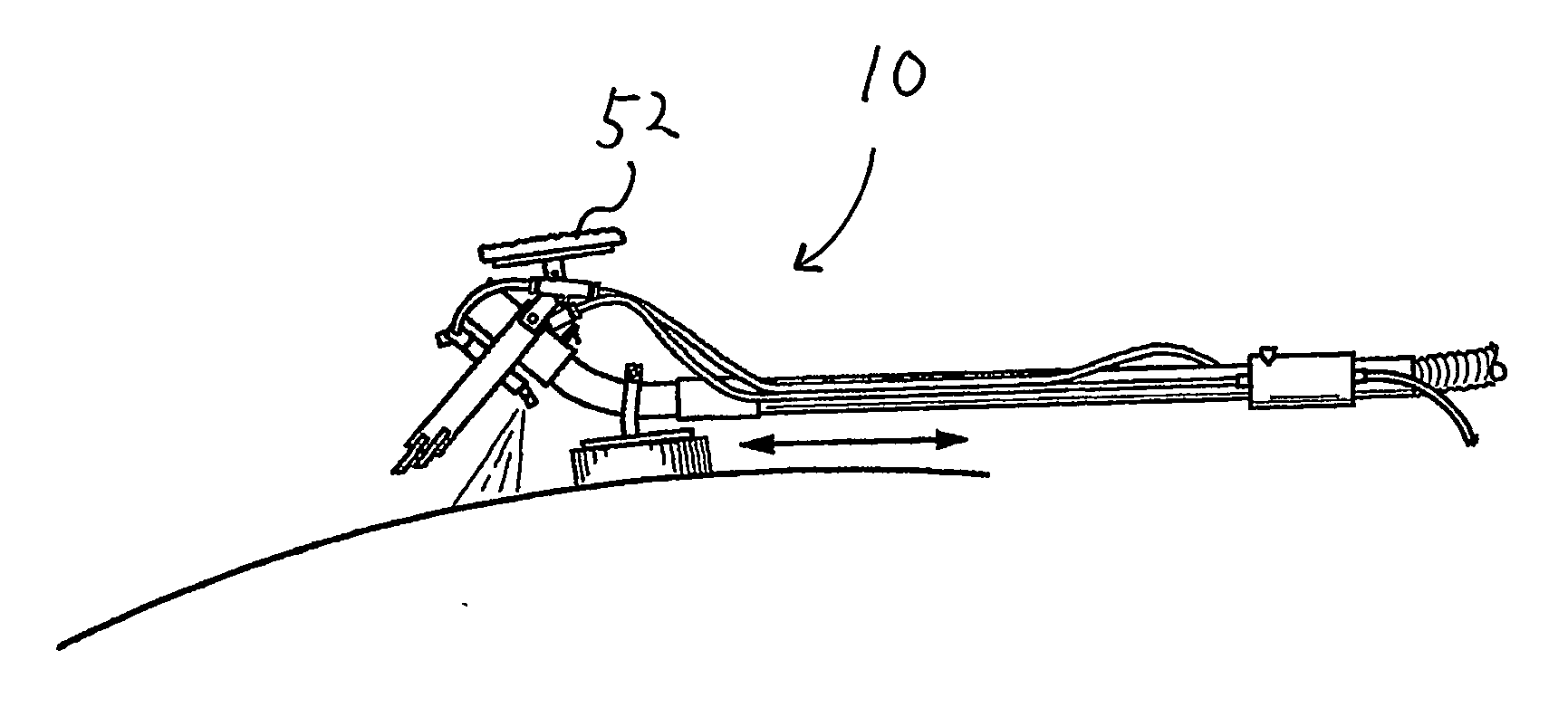

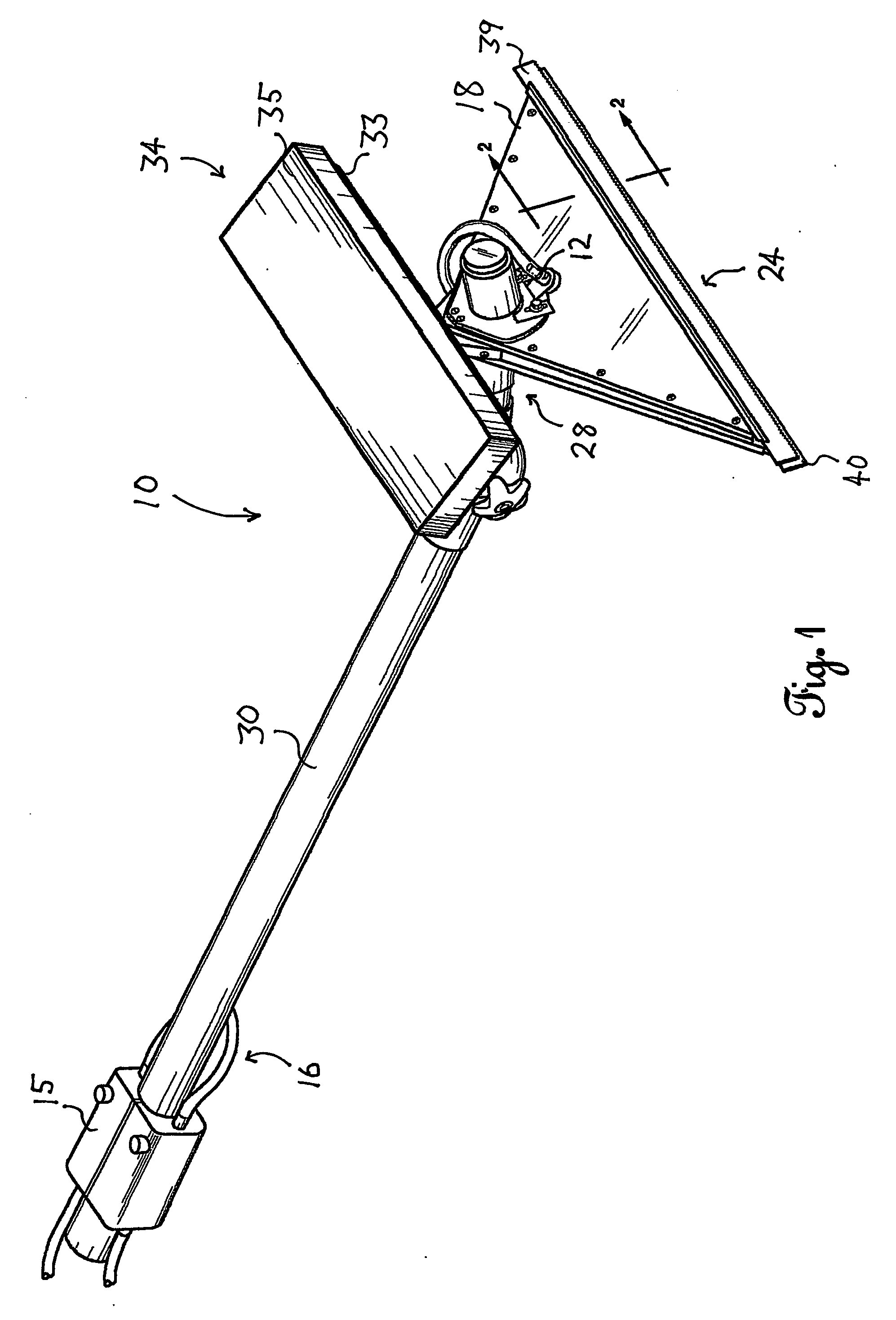

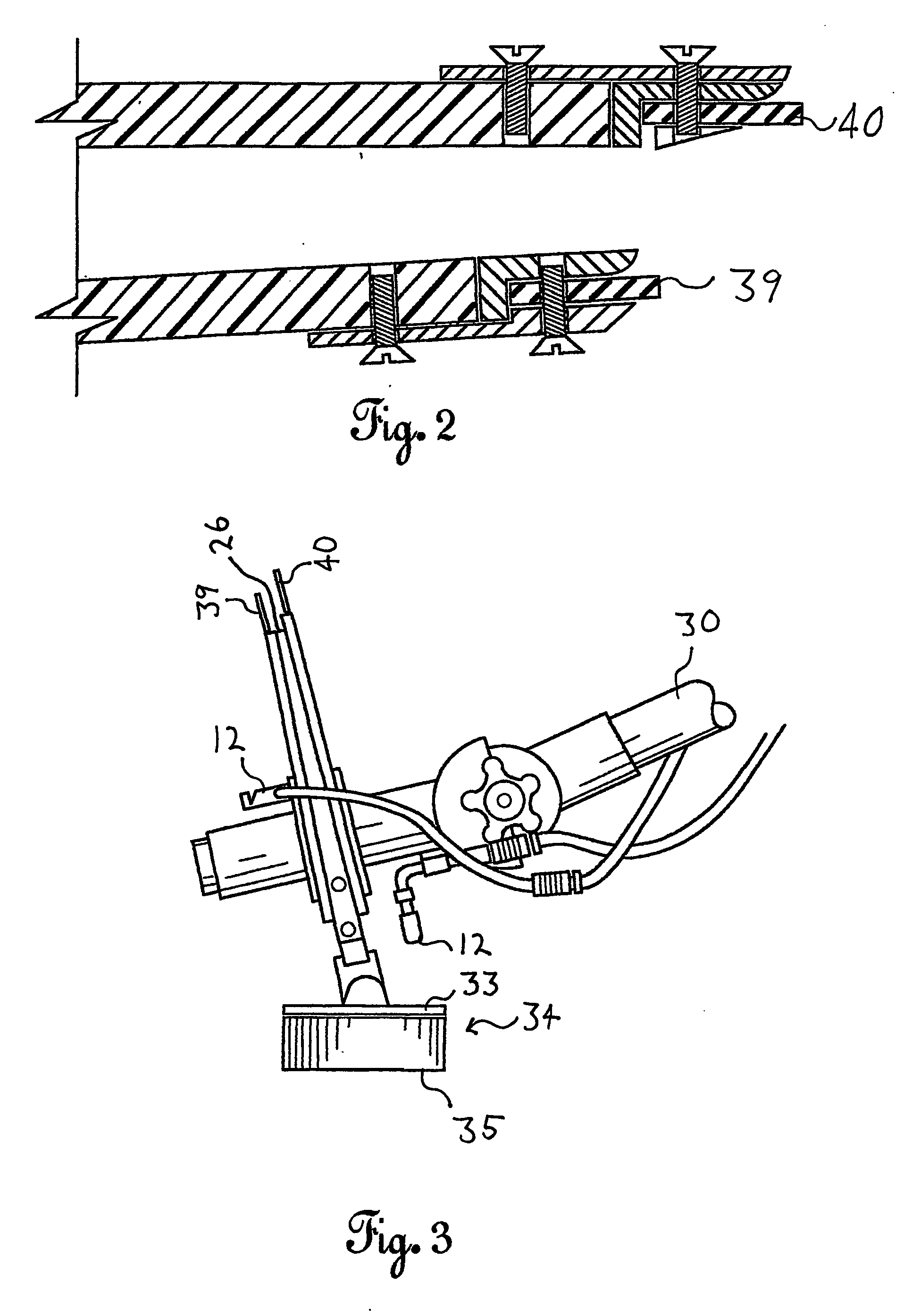

[0046] Referring in combination to FIGS. 1, 3, 4, 5, 6, 76A, 7A, 8, 8A, 8B, 9A, 9B, 10A, 10B, 10C, and 11, the head units 10 of Applicant's invention are designed to deliver cleaning solution in spray jet form, through spray nozzle(s) 12. Cleaning solution is delivered to nozzle(s) 12 by way of a conduit network 16 which, in turn, is in sealed fluid communication with a source of pressurized cleaning solution, such as via an aqueous pump 70 which, in turn, draws cleaning solution from a cleaning solution container 80. Soil-laden c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com