Superhard grinding tool and manufacturing method thereof

A technology for superhard abrasive tools and abrasive tools, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of complex process, high cost, high pollution, etc., and achieve simple process, low cost and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

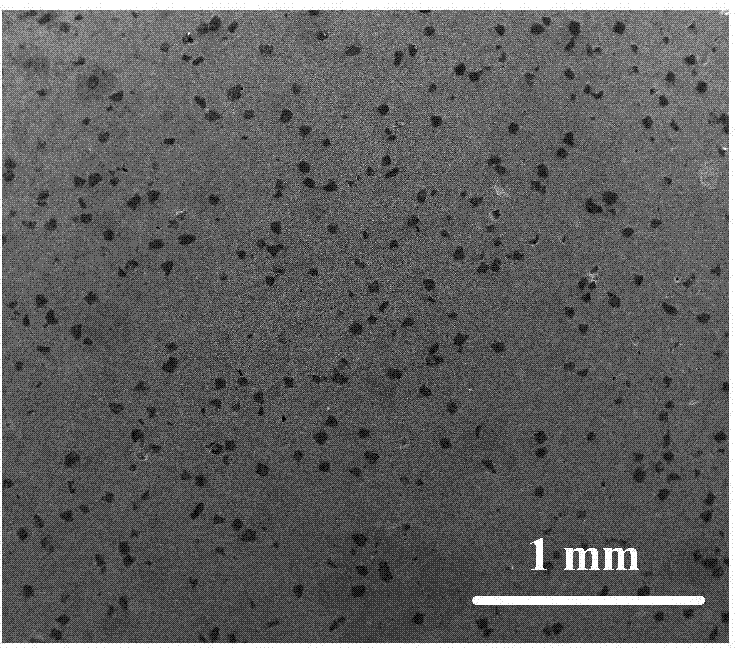

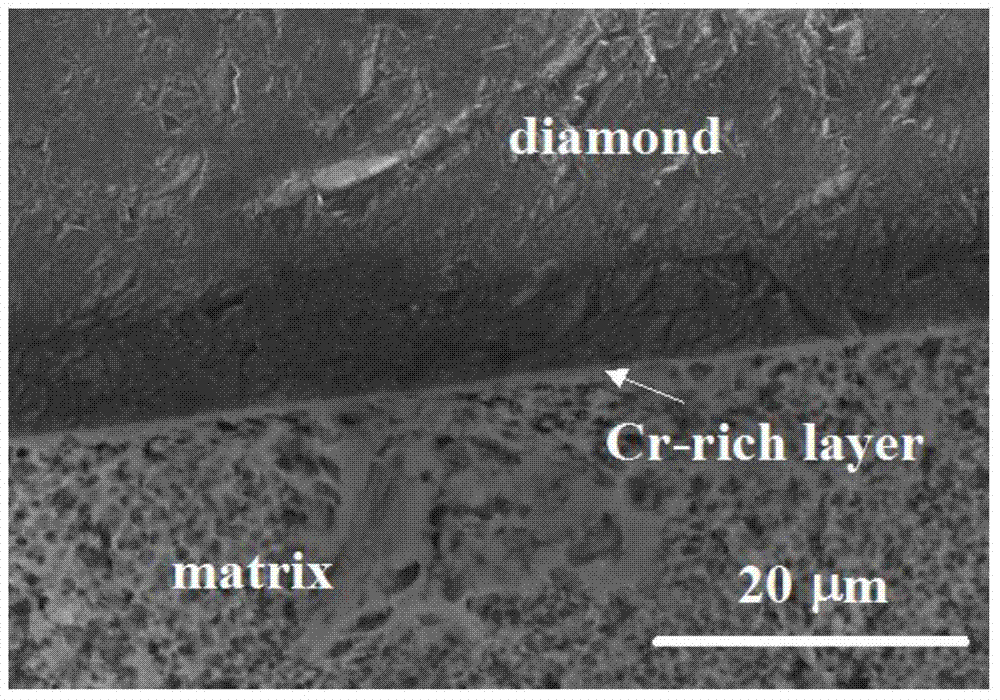

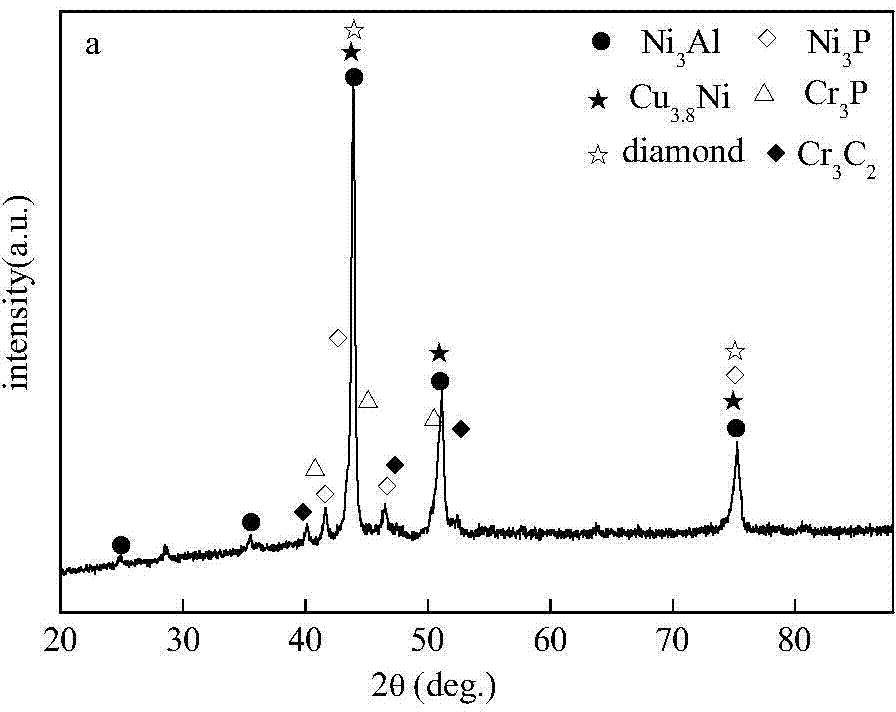

[0030] A kind of superhard abrasive tool, the raw material component of this superhard abrasive tool comprises binding agent and abrasive material, and described binding agent comprises Ni, Al, Cu, Ni-Cr alloy powder, wherein said Ni, Al are by molar ratio 3: 1 ratio, and its parts by weight are 20 parts in total, the parts by weight of Cu powder are 8 parts by weight, the parts by weight of Ni-Cr alloy powder are 60 parts, the abrasive is diamond, the concentration is 100%, and the particle size is 30 / 40 head.

[0031] A preparation method for a superhard abrasive tool, comprising the steps of:

[0032] Step (1), weighing the Ni, Al, Cu, Ni-Cr alloy powders of the above-mentioned components according to the proportion, and then putting them into a ball mill and fully mixing them to obtain abrasive tool bond powder, wherein the speed of the ball mill is 150r / min, the ball milling time is 3 hours, the ball-to-material ratio is 5:1, the total volume of balls and raw materials ...

Embodiment 2

[0037] A kind of superhard abrasive tool, the raw material component of this superhard abrasive tool comprises binding agent and abrasive material, and described binding agent comprises Ni, Al, Cu, Ni-Cr alloy powder, wherein said Ni, Al are by molar ratio 3: 1 ratio, and its parts by weight are 55 parts in total, the parts by weight of Cu powder are 12 parts by weight, the parts by weight of Ni-Cr alloy powder are 30 parts, the abrasive is diamond, the concentration is 50%, and the particle size is 50 / 60 head.

[0038] A preparation method for a superhard abrasive tool, comprising the steps of:

[0039] Step (1), weighing the Ni, Al, Cu, Ni-Cr alloy powders of the above-mentioned components according to the proportion, and then putting them into a ball mill and fully mixing them to obtain abrasive tool bond powder, wherein the speed of the ball mill is 170r / min, the ball milling time is 3.5h, the ball-to-material ratio is 6.5:1, and the total volume of balls and raw materia...

Embodiment 3

[0044]A kind of superhard abrasive tool, the raw material component of this superhard abrasive tool comprises binding agent and abrasive material, and described binding agent comprises Ni, Al, Cu, Ni-Cr alloy powder, wherein said Ni, Al are by molar ratio 3: 1 ratio, and its parts by weight are 41 parts in total, the parts by weight of Cu powder are 14 parts by weight, the parts by weight of Ni-Cr alloy powder are 38 parts, the abrasive is diamond, the concentration is 75%, and the particle size is 80 / 100 head.

[0045] A preparation method for a superhard abrasive tool, comprising the steps of:

[0046] Step (1), weighing the Ni, Al, Cu, Ni-Cr alloy powders of the above-mentioned components according to the proportion, and then putting them into a ball mill and fully mixing them to obtain abrasive tool bond powder, wherein the speed of the ball mill is 200r / min, the ball milling time is 4.5h, the ball-to-material ratio is 7.5:1, and the total volume of balls and raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com