Intermittent type gas protecting soldering furnace

A gas shielding and brazing furnace technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of slow temperature dynamic response, slow start-up work, poor flexibility, etc., to achieve fast temperature dynamic response, wide application range, Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

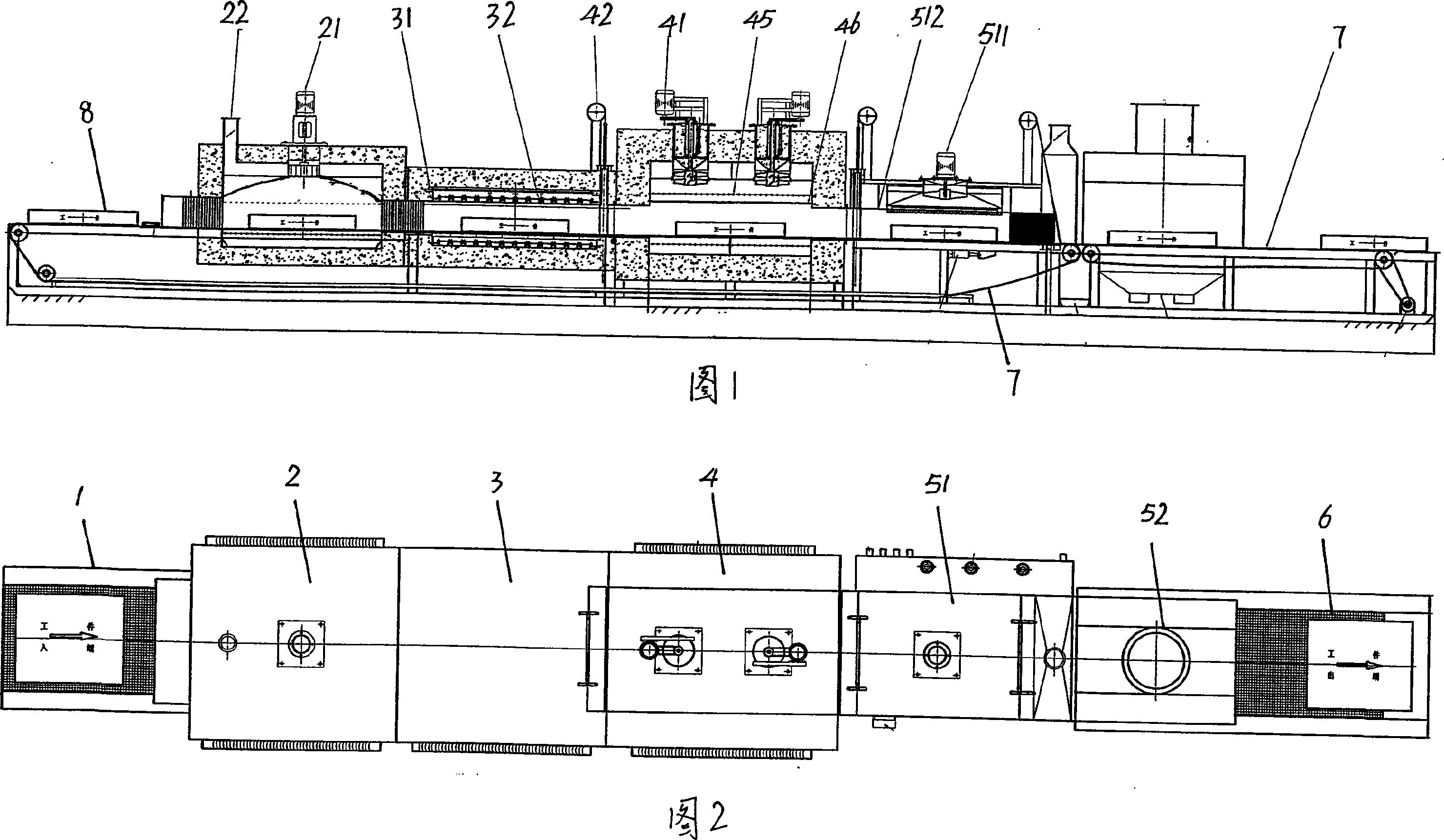

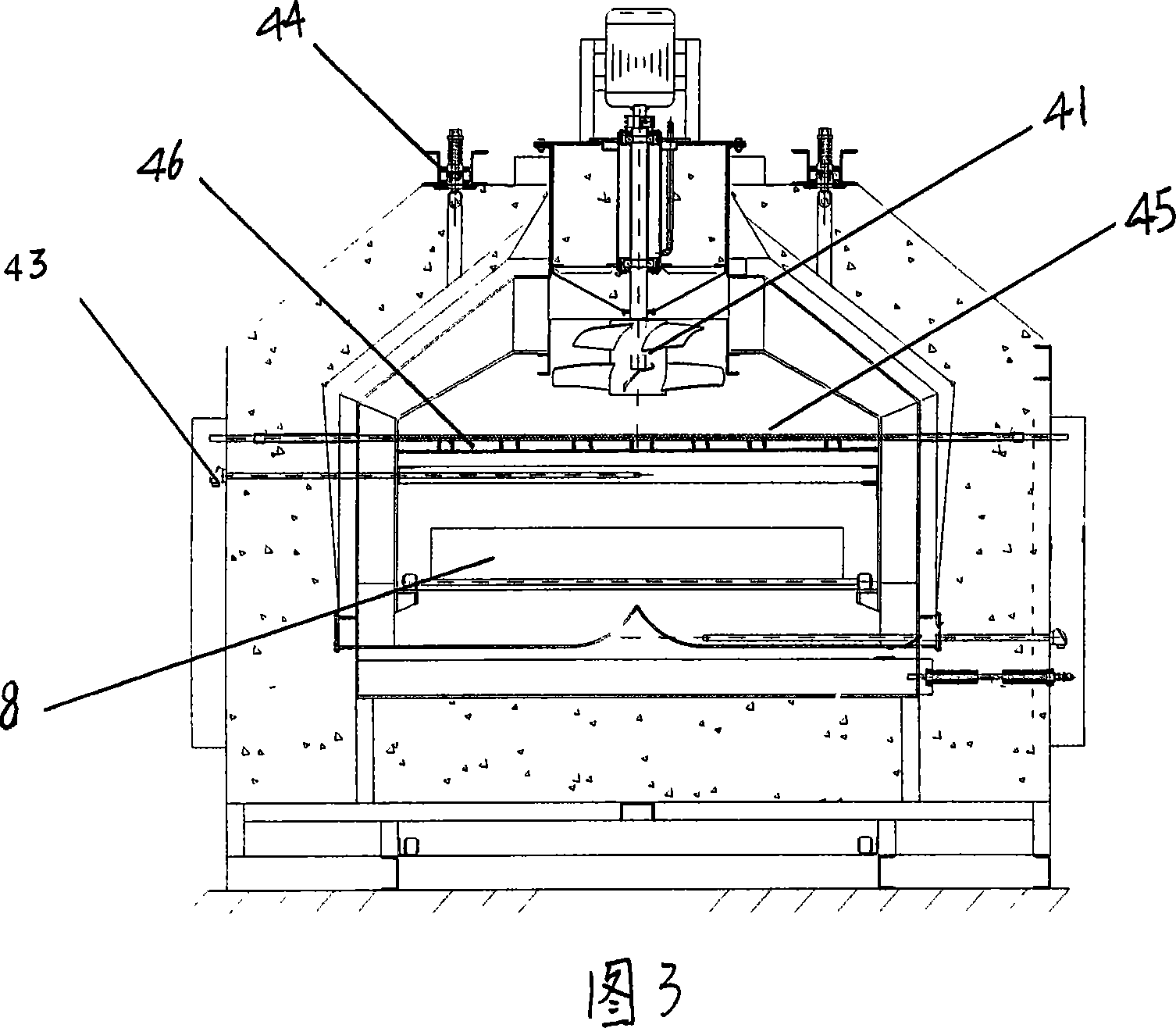

[0020] In the intermittent gas-shielded brazing furnace of the present invention, nitrogen is used as the shielding gas. It includes an upper part area 1, a heating and drying area 2, a preheating and purification area 3, a heating and brazing area 4, a cooling area 5, a lower part area 6 and a transmission belt 7; the inlet end of the heating and brazing area 4 passes through the preheating and purification area in turn 3 and the heating and drying area 2 are connected to the upper part area 1; the outlet end of the heating and brazing area 4 is connected to the lower part area 6 through the atmosphere-protected water cooling area 5 and the normal temperature air cooling area; the workpiece 8 is conveyed by the transmission belt 7. In the preheating and purifying zone 3, there is a preheating nitrogen inlet 31 and a purifying and compensating nitrogen device, and in the heating and brazing zone 4, there is an internal thermal cycle that blows the preheated nitrogen gas in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com