Forging process of plate element

A process and plate technology, which is applied in the field of plate forging process, can solve the problems of difficult correction, large outer circle size and thin thickness of mirror plates and head slabs, so as to avoid uneven hardness, meet processing requirements, Guarantee the effect of special requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

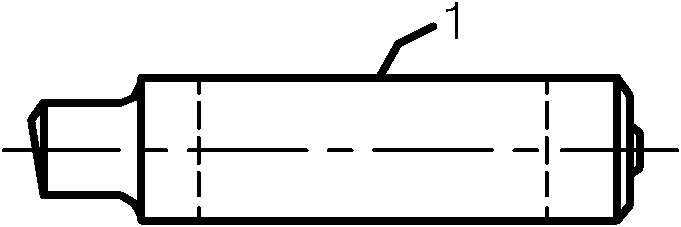

[0043] After heating the extra-large steel ingot 1 in a heating furnace with good furnace temperature uniformity, use a 160MN hydraulic press to follow the forging process of "cutting → upsetting, punching → reaming → elongating → reaming → gas cutting → flattening → gas cutting" The process produces mirror panels for 700MW units, and the results are as follows:

[0044] 1) From the results of flaw detection (UT-ultrasonic testing, MT-magnetic particle testing, PT-penetration testing), the mirror plate forgings did not find any defects that should be recorded, and the quality was good.

[0045] 2) Forging is easy, and it can effectively prevent quality problems such as concave center of the end face, eccentricity of inner and outer diameters, and warping of the end face during hole reaming.

[0046] 3) Uniform deformation during the forging process and consistent final forging temperature are more conducive to the refinement and uniformity of grains, fully ensuring the special...

Embodiment 2

[0049] The same forging process as in Example 1 is used to produce the head slab, but the inner hole in the slab 5 is not processed during the final gas cutting, that is, the head slab is formed, and the results are as follows:

[0050] 1) According to the results of flaw detection (UT, MT, PT), the head slab forgings did not find any defects that should be recorded, and the quality is good.

[0051] 2) The problem of the limitation of the head slab forming equipment is solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com