Laser deburring method and equipment

A deburring and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex processing technology, low processing efficiency and high cost, and achieve simple structure, high processing efficiency and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

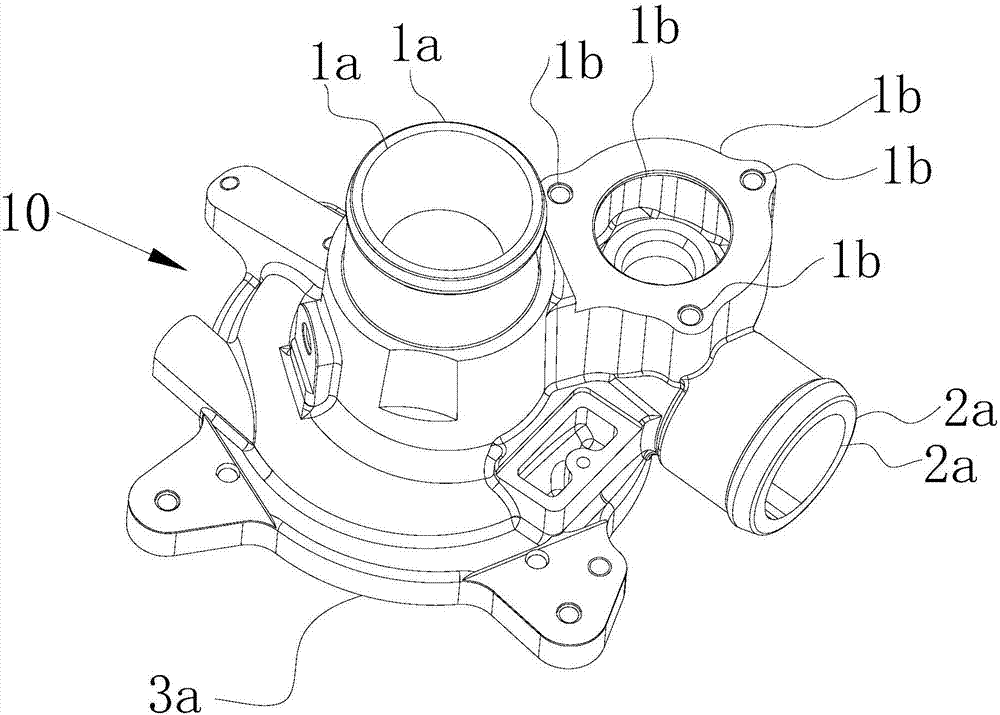

[0040] see figure 1 Shown is the turbine shell 10 that needs to be deburred in this embodiment. It is cast and has multiple processed surfaces. The position where two adjacent processed surfaces meet is often the position where burrs are generated and gathered. , the position where the two adjacent processing surfaces meet also forms the part that needs to be deburred, such as figure 1 1a, 1b, 2a, 3a in. The intersection lines between different processing surfaces also form the scanning trajectory of the laser beam scanning during laser processing and deburring. For example, the contour lines at 1a, 1b, 2a, and 3a are the corresponding scanning paths.

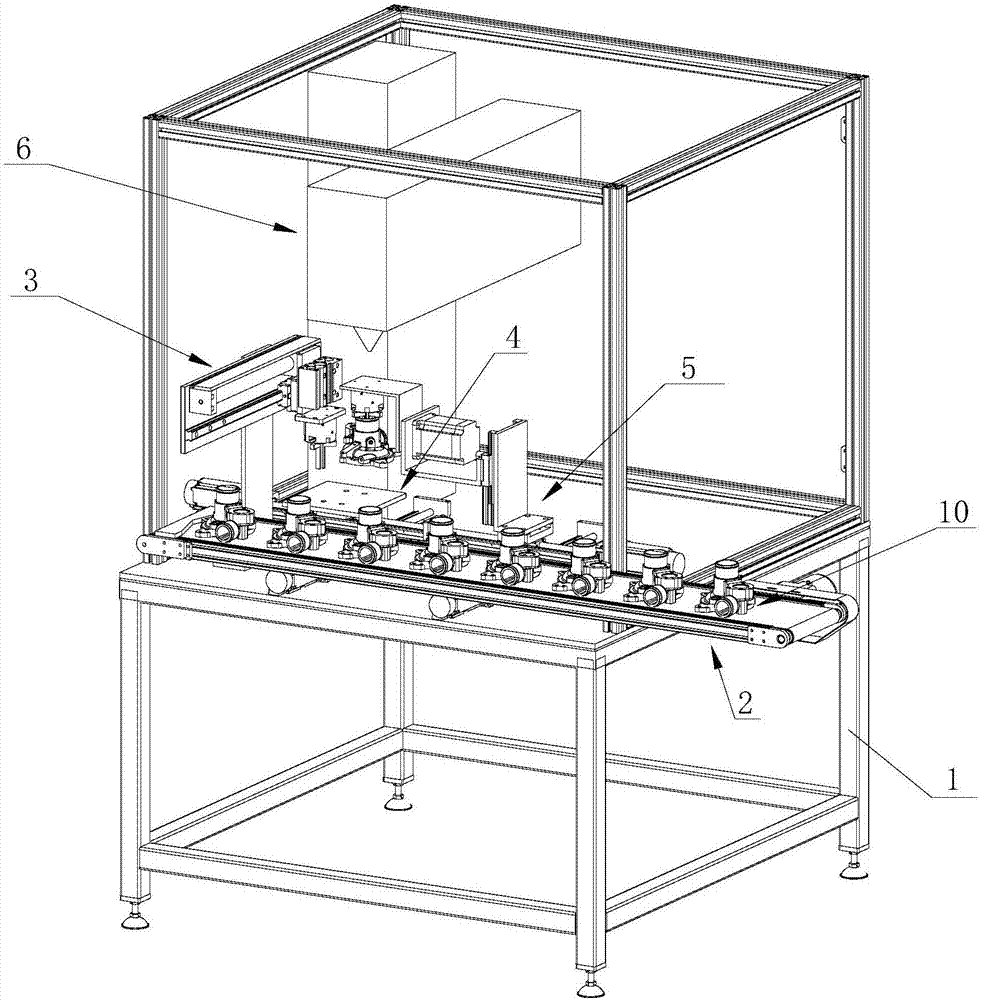

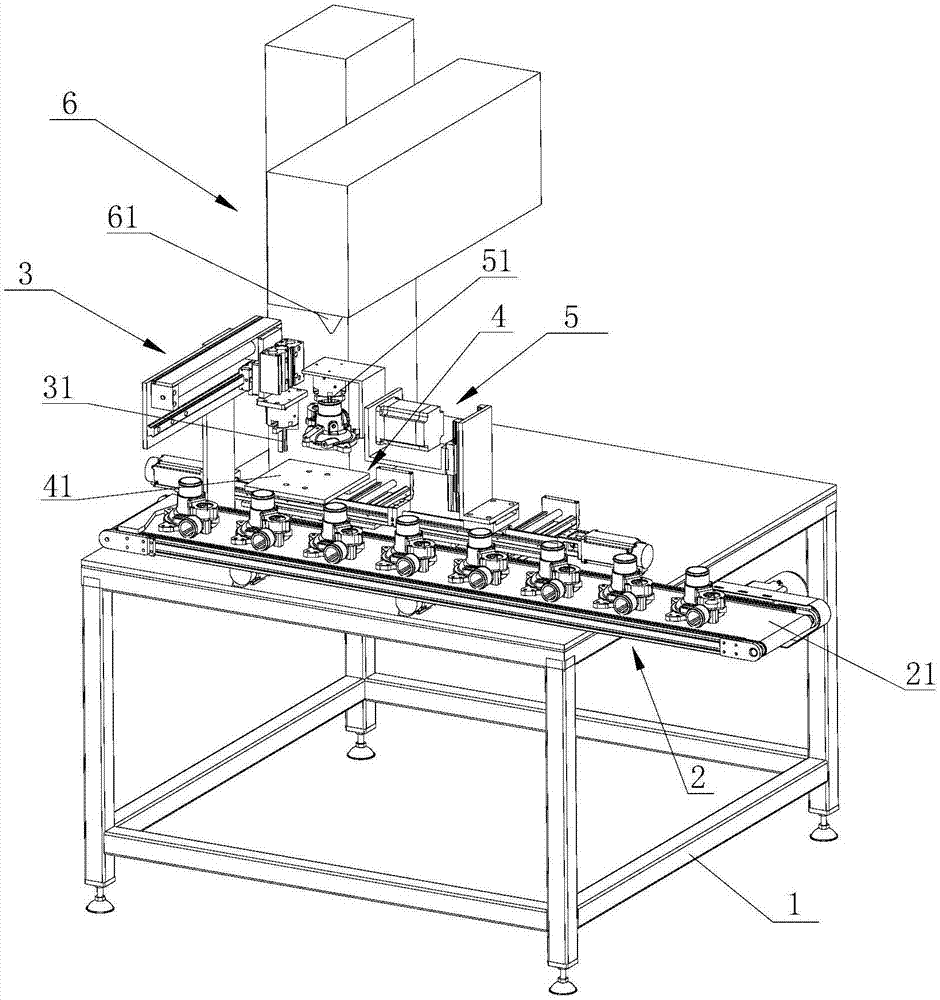

[0041] see figure 2 , image 3 Shown is the laser deburring equipment of this embodiment, which includes a base 1, a workbench 41 set on the base 1 for placing wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com