Method for treating iron-containing acidic wastewater

A waste water treatment and waste water technology, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc. The problems of ferrous oxidation speed and treatment effect are not stable, which can achieve the effect of short wastewater treatment time, simple operation and low operation and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

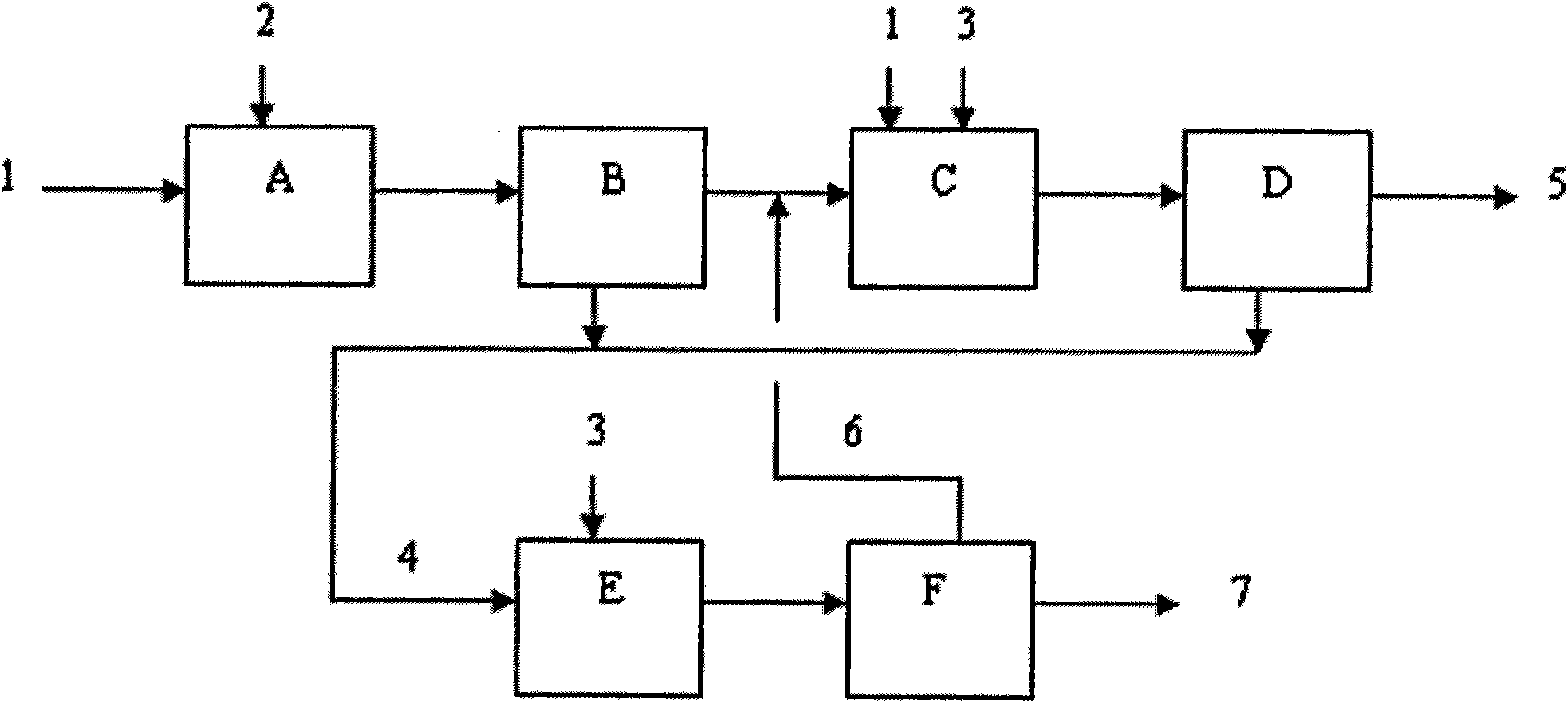

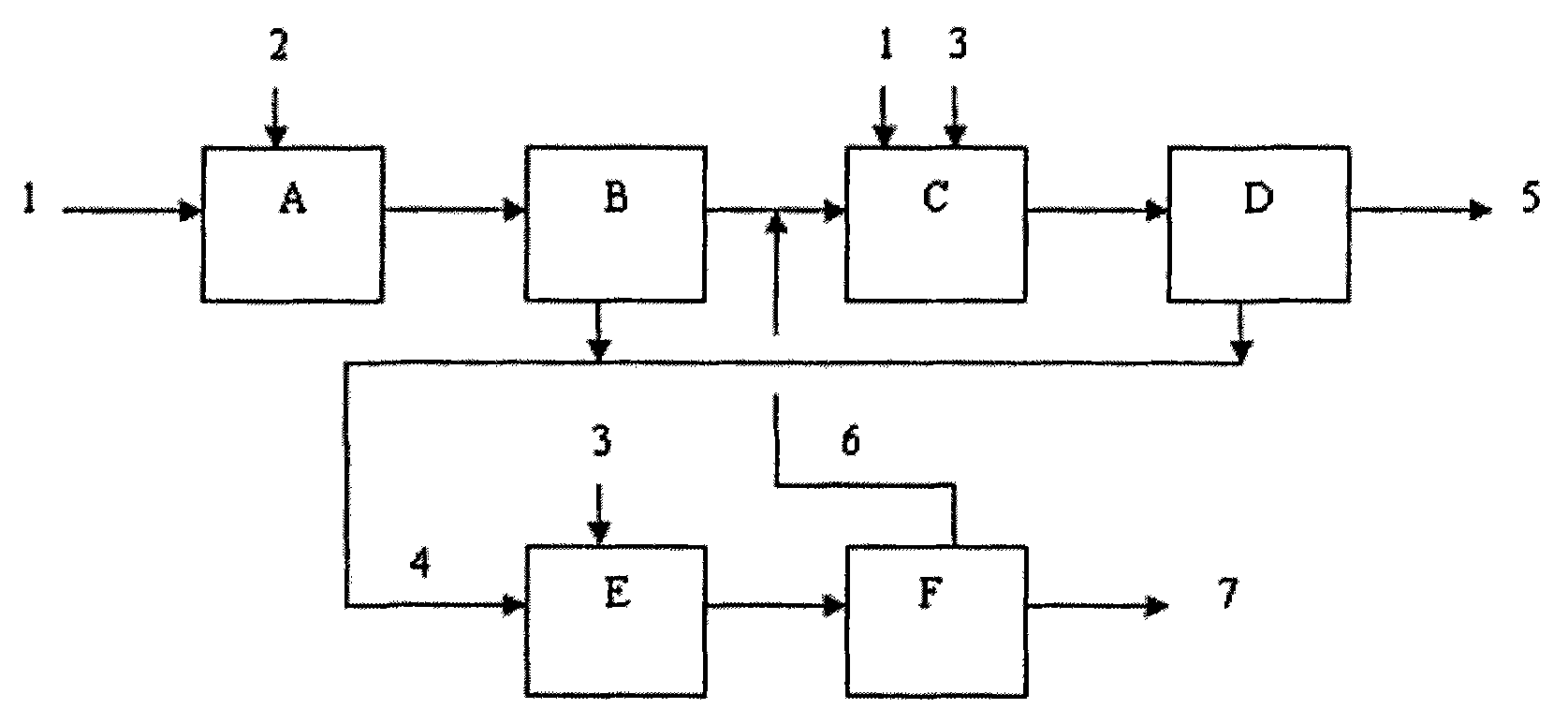

[0021] The technological process of the inventive method is referred to accompanying drawing. The acidic iron-containing wastewater 1 (pH 1.33-1.82, Fe content 1840-2260mg / L) from the production of titanium dioxide by the sulfuric acid method enters the neutralization tank A, and gradually adds calcium carbide slurry or lime milk 2 under mechanical stirring for neutralization Reaction, the pH value of the neutralization solution is 9.0-12.0, and the reaction time is 10-20 minutes; the neutralized slag-containing wastewater enters the sedimentation tank B, and the sedimentation time is 20-40 minutes; the supernatant wastewater from the sedimentation tank B enters the wastewater Oxidation pond C, waste water oxidation pond C is equipped with a pH adjustment area and an aeration area, in the pH adjustment area of waste water oxidation pond C, a small amount of acidic iron-containing wastewater 1 is used to adjust the pH, the pH adjustment value is 6-9, and then enters the aerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com