Atmosphere-corrosion-resistant cold heading steel hot rolled wire rod with grade being 10.9 and production method thereof

A technology of hot-rolled wire rods resistant to atmospheric corrosion, which is applied in the field of hot-rolled wire rods of 10.9-grade atmospheric corrosion-resistant cold heading steel for weather-resistant bolts and its production field, which can solve the problems of unreachable strength and achieve good surface quality and appearance quality Excellent, good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

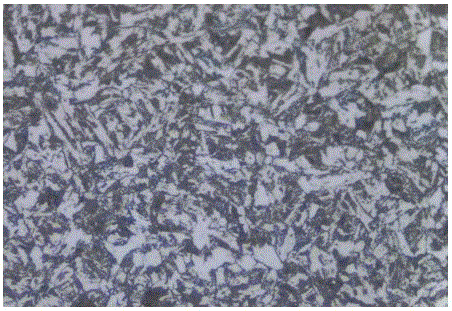

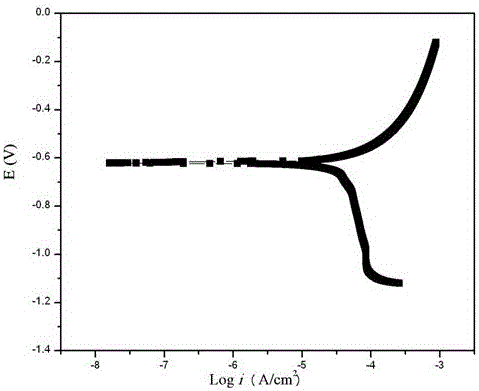

Image

Examples

Embodiment 1

[0016] Example 1: This 10.9-grade atmospheric corrosion-resistant cold-heading steel hot-rolled wire rod is produced by the following method.

[0017] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into slabs, the composition of which is by weight percentage: C 0.32%, Si0.20%, Mn 0.82%, P 0.020%, S 0.010%, Cr 0.81%, Ni 0.24%, Cu 0.25%, the rest is iron, and the corrosion resistance index is I=6.4.

[0018] (2) Heating process: heat the billet to 1100°C and hold for 85 minutes; then dephosphorize with high-pressure water at a temperature of 1040°C, requiring a water pressure of at least 10MPa.

[0019] (3) Rolling process: the dephosphorized steel billet is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of entering and finishing rolling is 895°C. After finishing rolling, spinning The temperature is controlled at 880°C.

[0020] (4) Cooling pr...

Embodiment 2

[0022] Example 2: This 10.9-grade atmospheric corrosion-resistant cold heading steel hot-rolled wire rod is produced by the following method.

[0023] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into steel slabs, and its composition by weight percentage is: C 0.28%, Si0.22%, Mn 0.80%, P 0.021%, S 0.013%, Cr 0.83%, Ni 0.26%, Cu 0.26%, the rest is iron, and the corrosion resistance index is I=6.6.

[0024] (2) Heating process: heat the steel billet to 1080°C, hold for 90 minutes; then remove phosphorus with high-pressure water, the temperature of phosphorus removal is 1020°C, and the water pressure for phosphorus removal is required to be at least 10MPa.

[0025] (3) Rolling process: the dephosphorized steel billet is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of finishing rolling is 905°C. After finishing rolling, spinning The temperatu...

Embodiment 3

[0028] Embodiment 3: This 10.9-grade atmospheric corrosion-resistant cold-heading steel hot-rolled wire rod is produced by the following method.

[0029] (1) Smelting and continuous casting process: molten steel is smelted and continuously cast into steel slabs, and its composition by weight percentage is: C 0.30%, Si0.15%, Mn 0.85%, P 0.022%, S 0.012%, Cr 0.79%, Ni 0.35%, Cu 0.50%, the rest is iron, and the corrosion resistance index is I=6.4.

[0030] (2) Heating process: heat the steel billet to 1100°C, hold for 100 minutes; then remove phosphorus with high-pressure water, the temperature of phosphorus removal is 1040°C, and the water pressure for phosphorus removal is required to be at least 10MPa.

[0031] (3) Rolling process: the slab after dephosphorization is subjected to 6+8 passes of rough and intermediate rolling, 4 passes of pre-finish rolling, 8 passes of finish rolling, and the temperature of finishing rolling is 900°C. After finishing rolling, spinning The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com