CMR-grade high-flame-retardation polyvinyl chloride cable jacket material and preparation method of same

A technology of polyvinyl chloride and sheathing material, which is applied in the direction of cables, insulated cables, conductors, etc., can solve the problem of low oxygen index of cable sheathing material, achieve the effect of reducing dosage and increasing flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

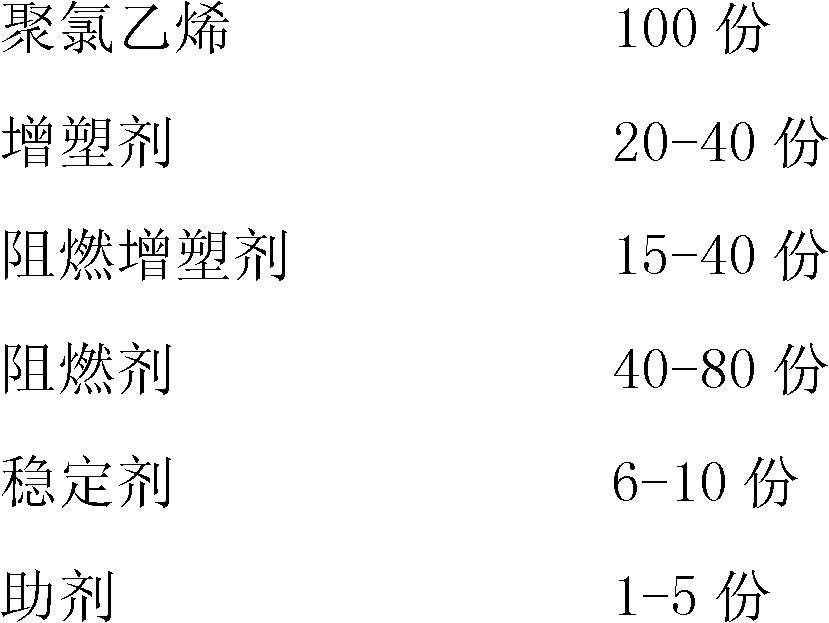

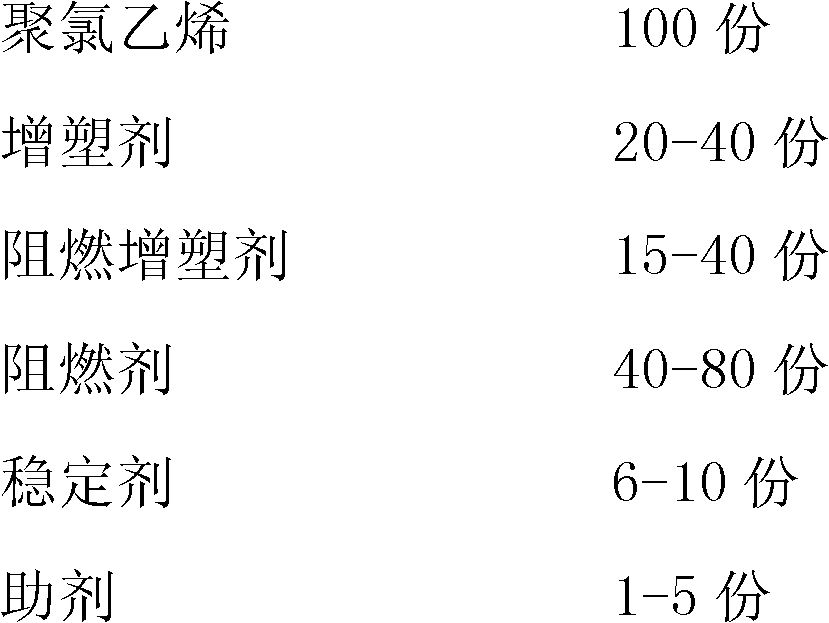

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the cable sheathing material, comprising the following steps:

[0025] S1. Preparation of flame retardant plasticizer mixture: mix resorcinol bis(diphenyl phosphate), dioctyl tetrabrominated phthalate and tris(2,3-dichloropropyl)phosphate evenly ;

[0026] S2. Ingredients: Pour polyvinyl chloride into the high mixer, heat to 90-100°C while stirring, add the flame retardant plasticizer mixture prepared in step S1 and stir evenly, then add the plasticizer and stir evenly, Finally, add flame retardant, stabilizer and additives and stir evenly;

[0027] S3. Extrusion granulation: adding the mixture obtained in step S2 to a twin-screw extruder for granulation to obtain a cable sheath material.

[0028] Preferably, the operating temperature of the twin-screw extruder is 140°C-160°C, the feeding frequency is 20 Hz, and the rotational speed of the main engine is 300 rpm.

Embodiment 1

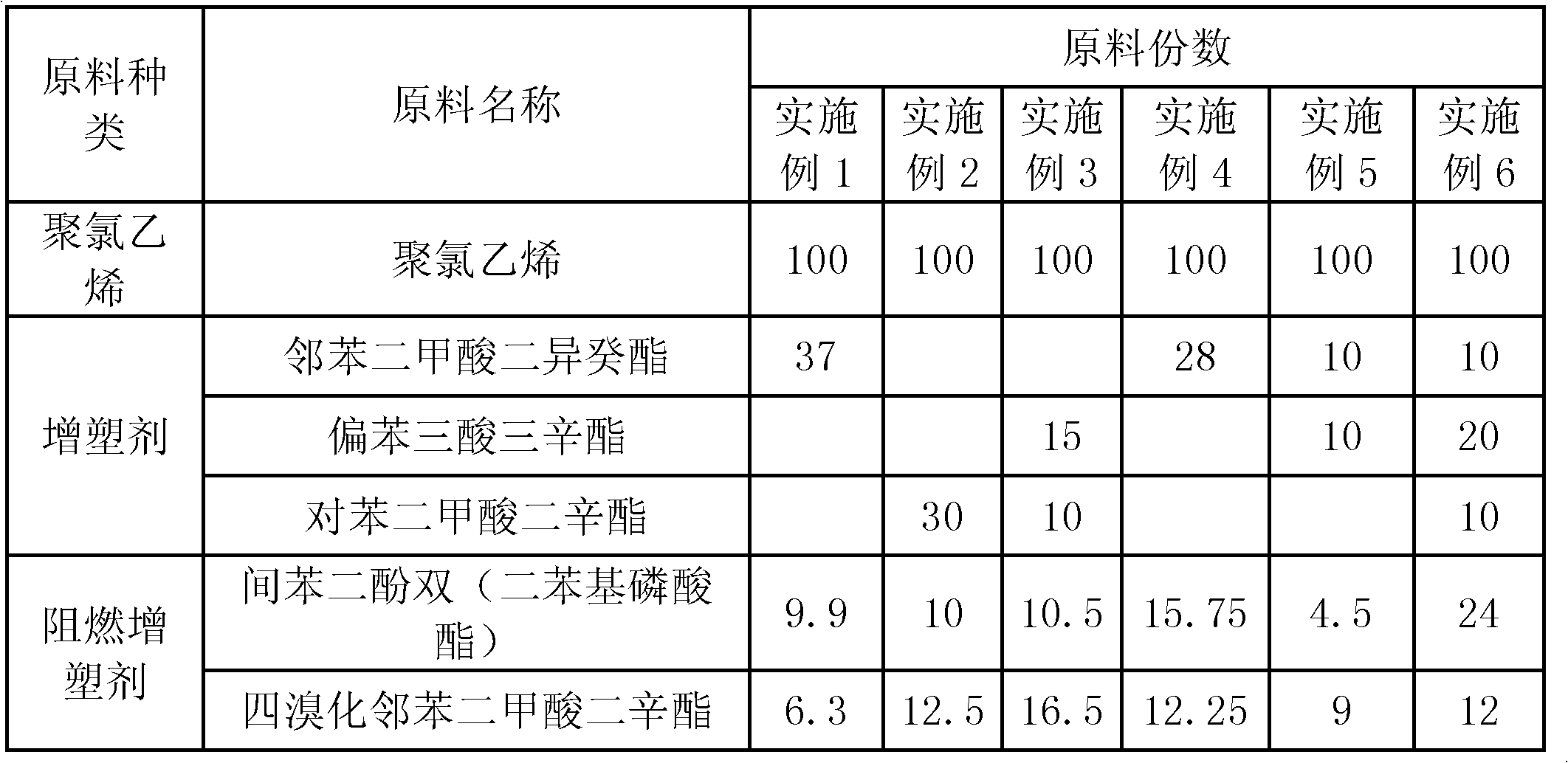

[0031] 1. Weighing: according to the formula described in the following Table 1, Example 1, weigh the corresponding substances for subsequent use;

[0032] 2. Preparation of flame retardant plasticizer mixture: weighed resorcinol bis(diphenyl phosphate), dioctyl tetrabrominated phthalate, tris(2,3-dichloropropyl phosphate) ) ester into the stirring tank, fully stirred until uniformly miscible for subsequent use;

[0033] 3. Ingredients: Pour polyvinyl chloride into the high-mixer, heat to 100°C while stirring, add the mixed liquid prepared in step 2, stir for 5 minutes, add the weighed plasticizer, and stir for 5 minutes; then Add the remaining flame retardants, stabilizers and additives in sequence, and stir evenly at high speed.

[0034] 4. Extrusion granulation: Discharge the prepared and mixed materials from the mixer, put them into the feeding hopper of the twin-screw extruder, and evenly add them into the twin-screw extruder from the feeder. The temperature of the extr...

Embodiment 2-7

[0039] Samples A2-A6 were prepared according to the method of Example 1 and the content of each formulation of Examples 2-6 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com