Composite cladded lithium ion cathode material, and preparation method thereof

A cathode material, lithium fast ion technology, applied in the field of composite coated lithium ion battery cathode material and its preparation, can solve the problems of poor conductivity, instability, material capacity decay and the like of the cathode material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

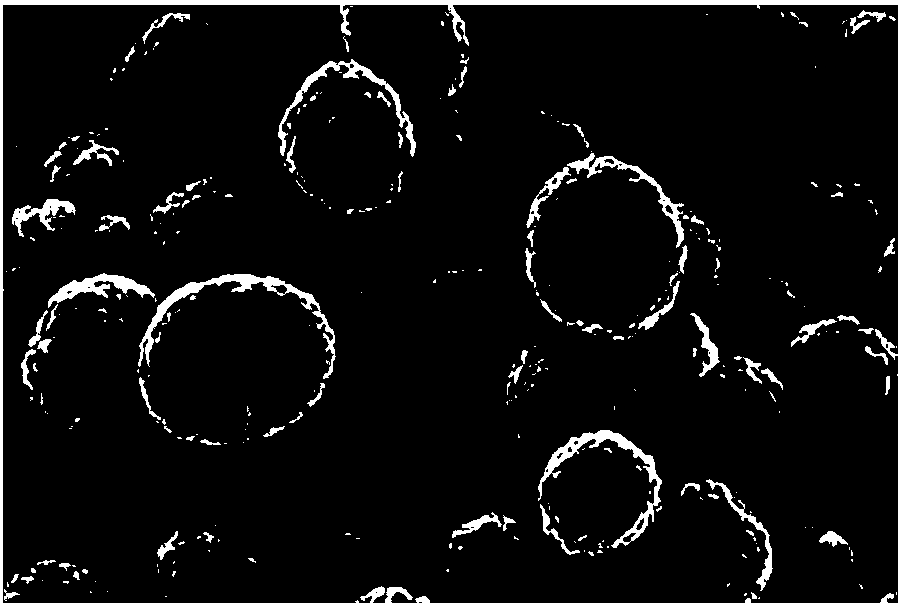

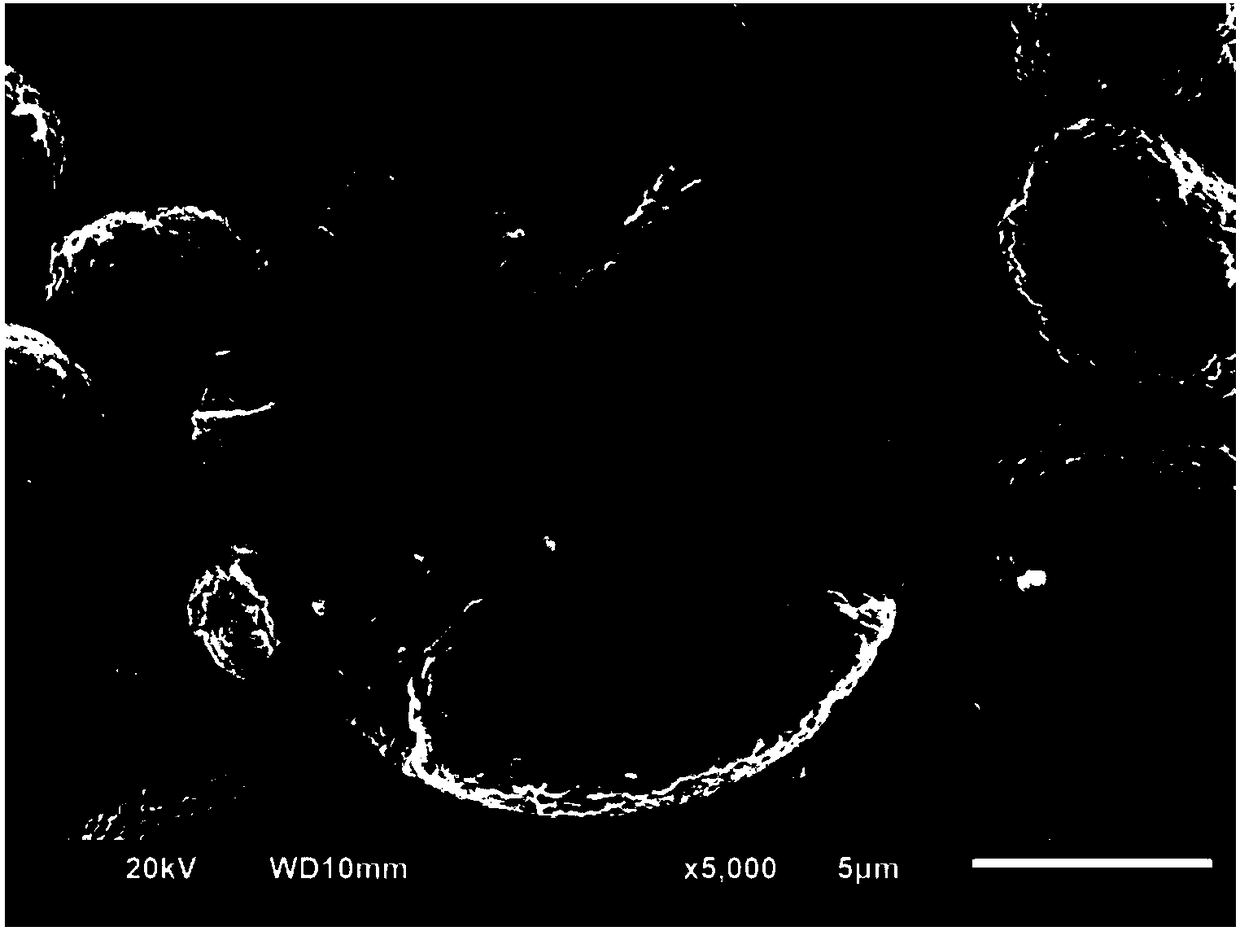

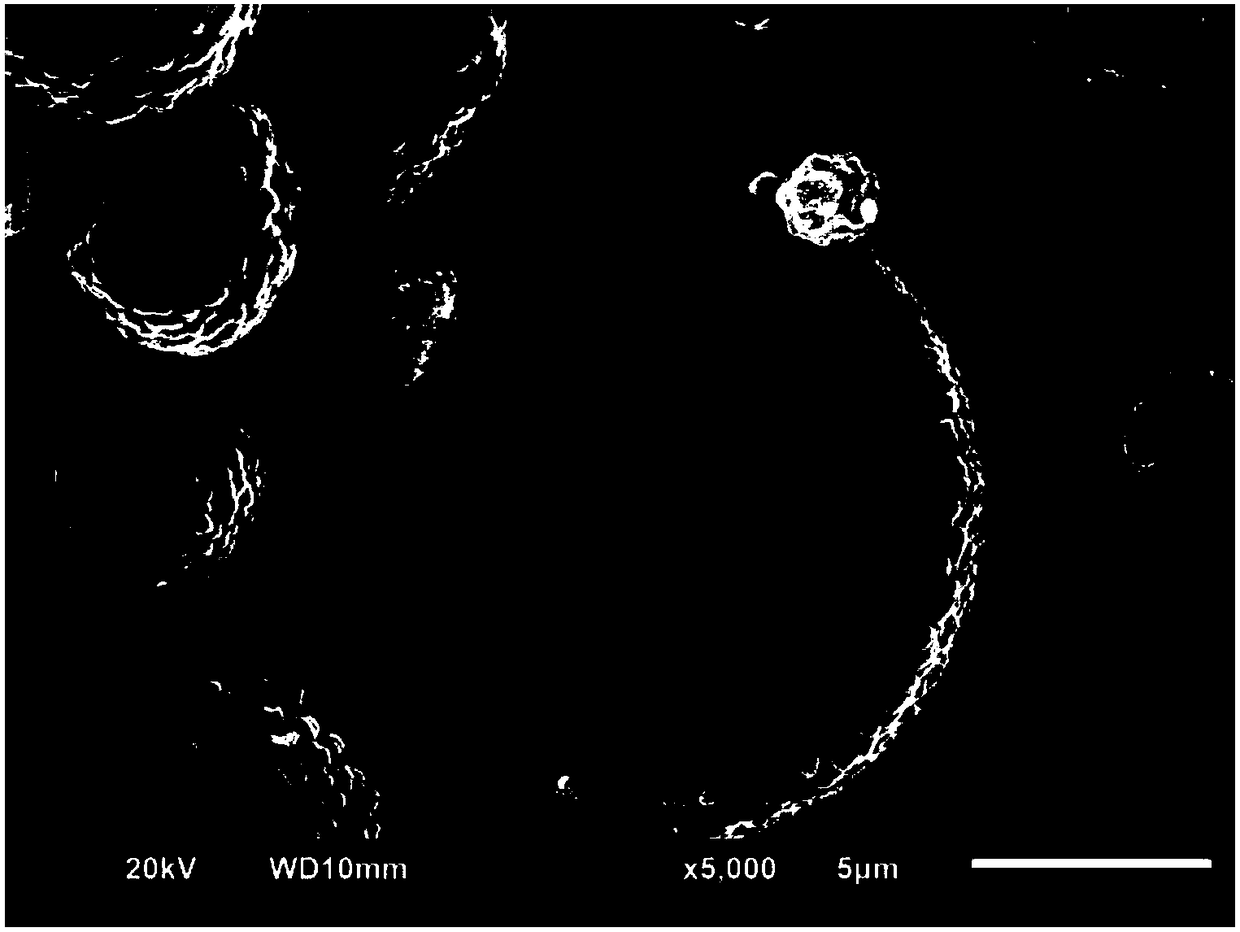

Image

Examples

Embodiment approach

[0043] According to a preferred embodiment of the present invention, the conductive cladding layer includes a lithium fast ion conductor material.

[0044] Among them, the lithium fast ion conductor has better lithium ion conductivity, which can increase the migration rate of lithium ions, thereby improving the electrical properties of the positive electrode material. However, the lithium fast ion conductor improves the ion conductivity.

[0045] According to a preferred embodiment of the present invention, the conductive cladding layer further includes an electronic conductor material.

[0046] Wherein, the conductive cladding layer is also doped with an electronic conductor material, which further improves the electronic conductivity of the positive electrode material.

[0047] According to a preferred embodiment of the present invention, the weight ratio of the conductive coating layer to the substrate is (0.1˜1.0):100.

[0048] In a further preferred embodiment, the weigh...

Embodiment 1

[0117] Disperse 0.20 g of ammonium dihydrogen phosphate and 0.12 g of lithium hydroxide in 100 g of water, stir and mix for 40 minutes to form a conductive coating layer solution;

[0118] Adding 100g of nickel-cobalt-lithium-aluminate cathode material into the conductive coating layer solution, and stirring to obtain a mixed solution;

[0119] Stir the above mixed solution, and carry out stirring at 150° C. for 5 h, evaporate the mixed solution to dryness to obtain a dry powder;

[0120] The above dry powder was annealed at 900° C. for 15 hours, then ground and pulverized, and passed through a 300-mesh sieve to obtain a composite-coated lithium-ion battery positive electrode material.

Embodiment 2

[0122] Disperse 0.20 g of ammonium dihydrogen phosphate and 0.12 g of lithium hydroxide in 100 g of water, add 0.4 g of graphene after stirring for 10 minutes, and stir and mix for 40 minutes to form a conductive coating layer solution;

[0123] Adding 100g of nickel-cobalt-lithium-aluminate cathode material into the conductive coating layer solution, and stirring to obtain a mixed solution;

[0124] Stir the above mixed solution, and carry out at 80° C. for 10 h under stirring, and evaporate the mixed solution to dryness to obtain a dry powder;

[0125] The above dry powder was annealed at 700° C. for 15 hours, then ground and pulverized, and passed through a 300-mesh sieve to obtain a composite-coated lithium-ion battery positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com