Control method of light emitting diode (LED) constant current power supply and LED constant current power supply circuit

A technology of control circuit and constant current power supply, applied in the direction of electric lamp circuit layout, electric light source, energy-saving control technology, etc., can solve the problems of adverse effects of mass production consistency, poor adaptability, large interference, etc., to achieve consistency guarantee, reduce Electromagnetic radiation, the effect of simplifying the control circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

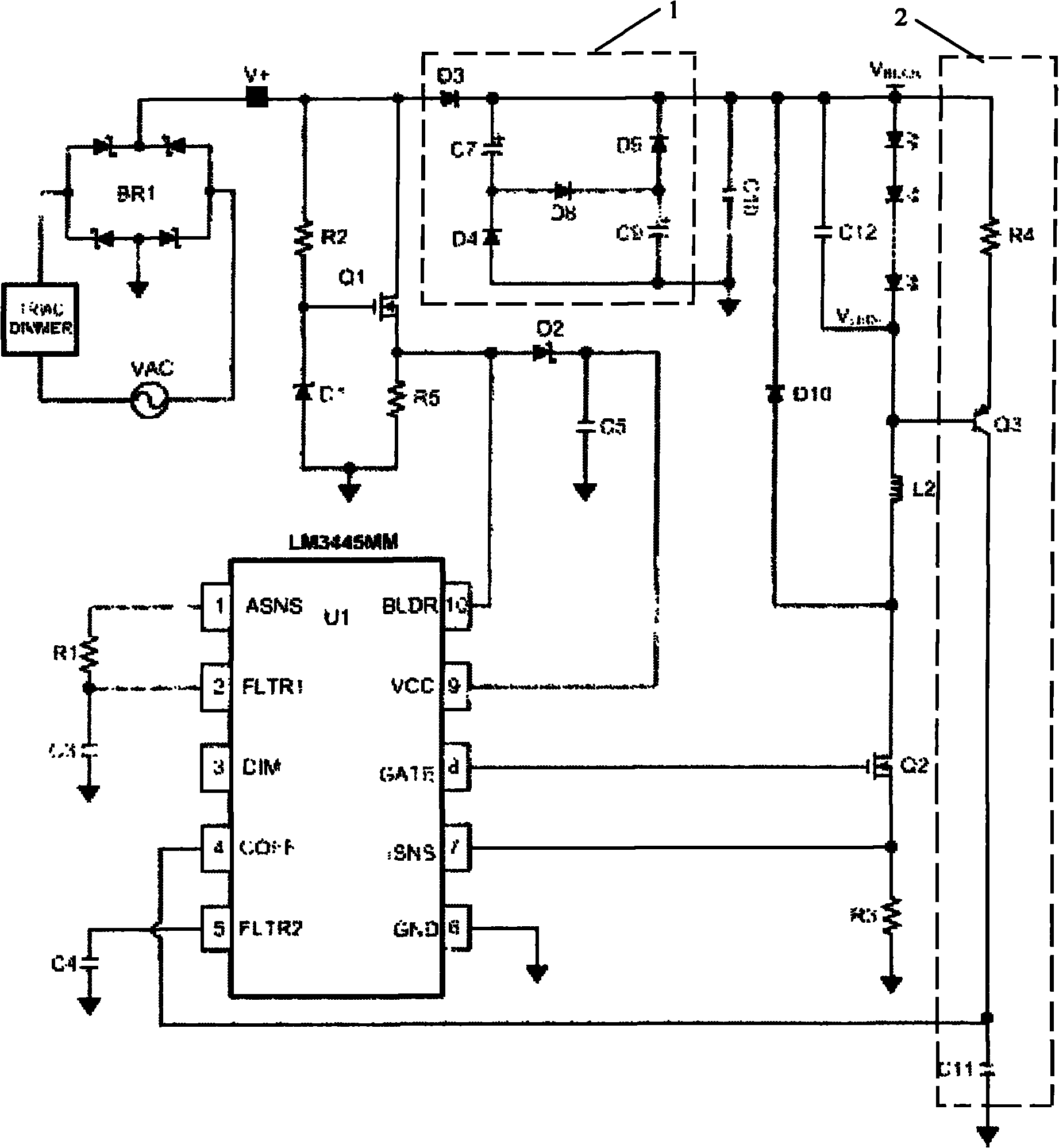

[0043] see Figure 4 , this embodiment is an LED constant current power supply circuit using the control method of the present invention, which includes a control circuit, a power supply unit, an input voltage detection unit, an output frequency jitter control unit, an output voltage waveform detection unit, A primary side current detection unit, a switch tube S1, and a high frequency transformer L.

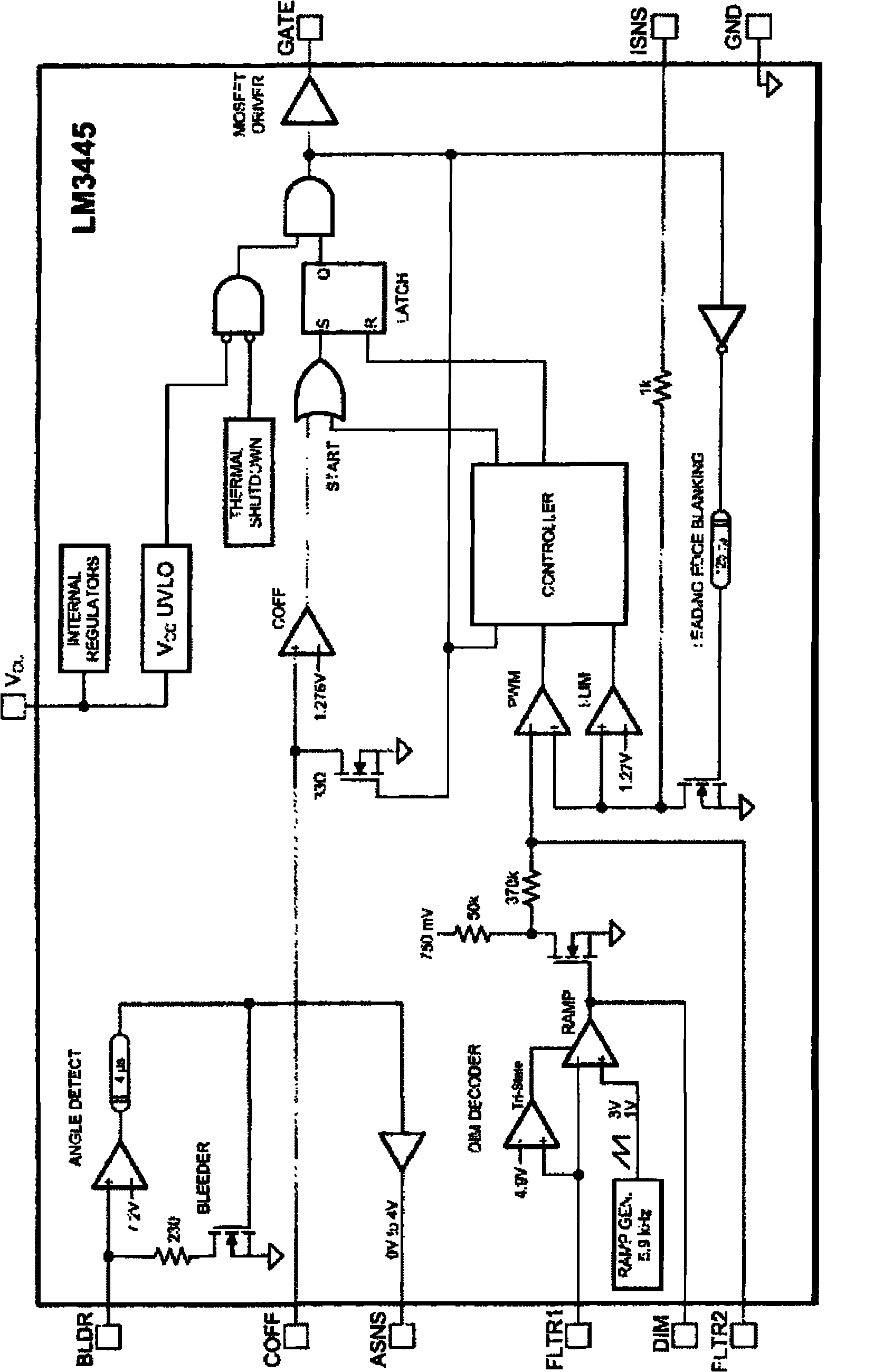

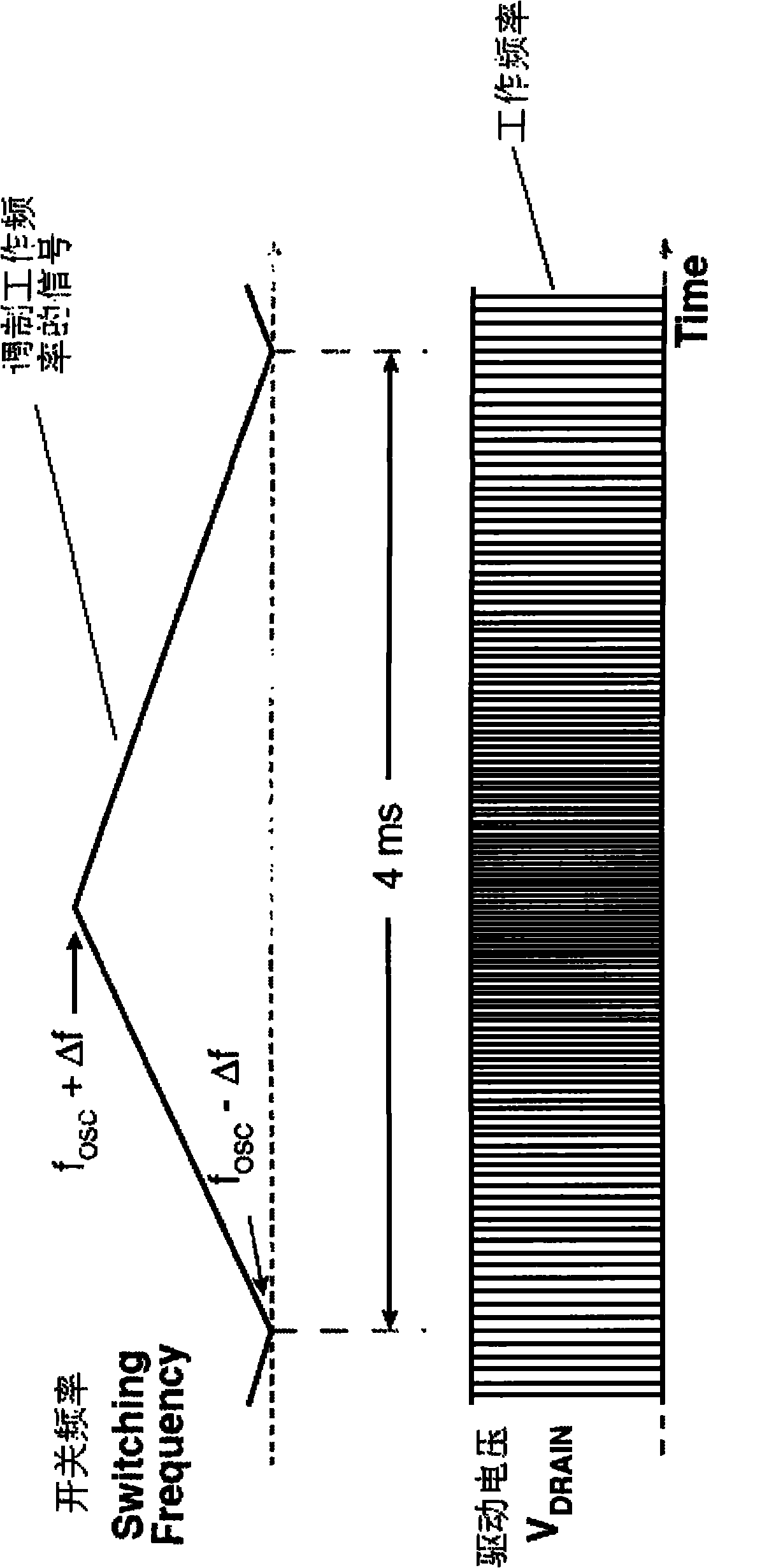

[0044] see Figure 4 with Figure 5 , the control circuit is used to convert the input voltage signal, input current signal, and feedback voltage signal into digital signals, and add a frequency dither signal for a preset time to obtain a pulse signal for controlling the operation of the switch tube through logical operation.

[0045] see Figure 5 , the control circuit in this embodiment includes a start-up circuit, a logical operation unit, an output drive unit, a voltage unit, an input voltage detection unit, a voltage waveform generation unit, 5 comparator units and an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com