Method for unsealing plastically-packaged apparatus containing un-passivated metal layer structure

A passivation metal and layer structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to continue inspection, structural damage, loss of function of product devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

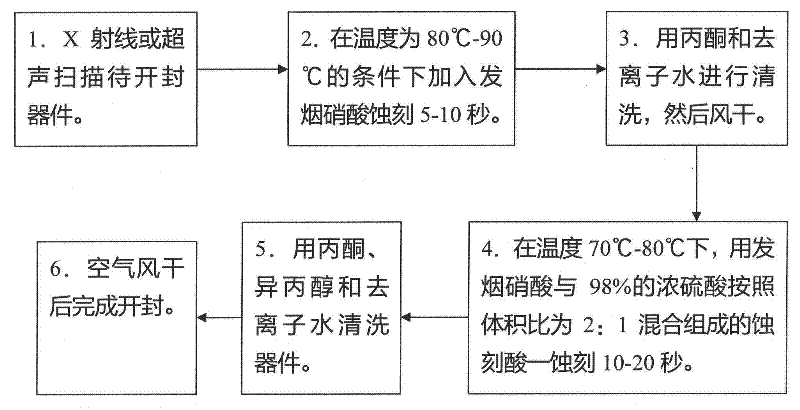

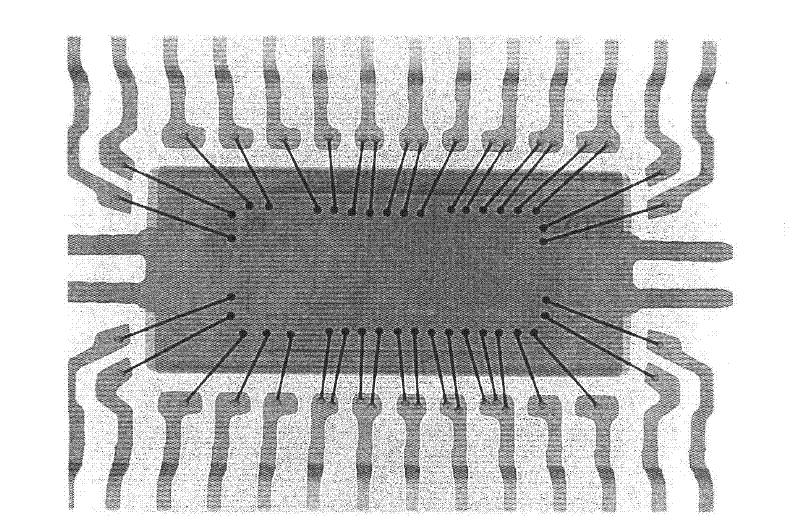

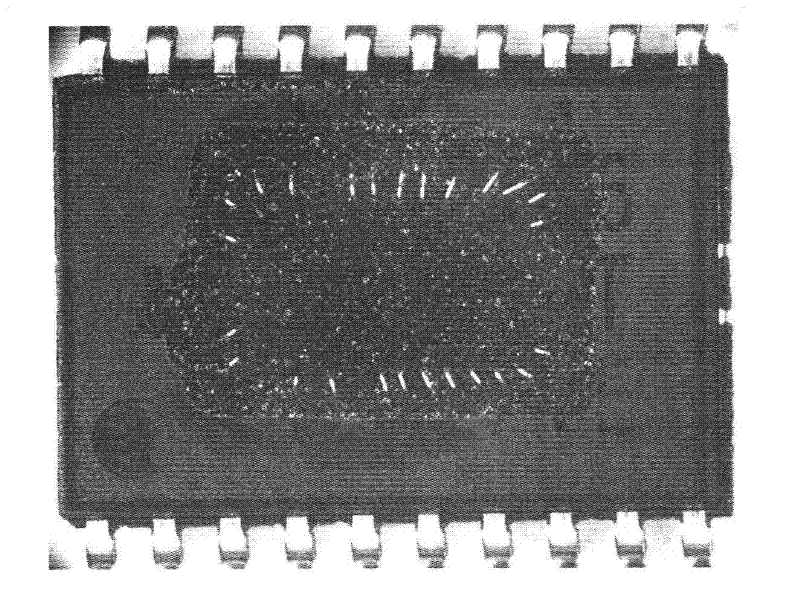

[0020] In order to further illustrate the technical means and effects that the present invention takes to achieve the predetermined purpose, the following in conjunction with the accompanying drawings and preferred embodiments, the unsealing method for the plastic packaged device containing the non-passivated metal layer structure proposed according to the present invention, its specific Embodiments, structures, features and effects thereof are described as follows.

[0021] The unsealing method of the plastic-encapsulated device containing the unpassivated metal layer structure provided by the present invention is based on the unsealing method of the destructive physical analysis (DPA) and failure analysis (FA) of the plastic-encapsulated semiconductor device containing the unpassivated metal layer structure, specifically In order to use etching acid to etch the plastic packaging device for 10-20 seconds under the environment of 70°C-80°C, the etching acid-is composed of fumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com