Dental implant and surface treatment method thereof

A technology for dental implants and dental implants, applied in the field of dental implants and their surface treatment, can solve the problems of ozone generation, injury protection, medical staff and patients, and inconvenient clinical use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A dental implant, the surface of which is treated by:

[0037] 1) Cleaning of pure titanium dental implants: Ultrasonic cleaning of pure titanium dental implants with acetone, absolute ethanol, and deionized water for 15 minutes each, and natural drying;

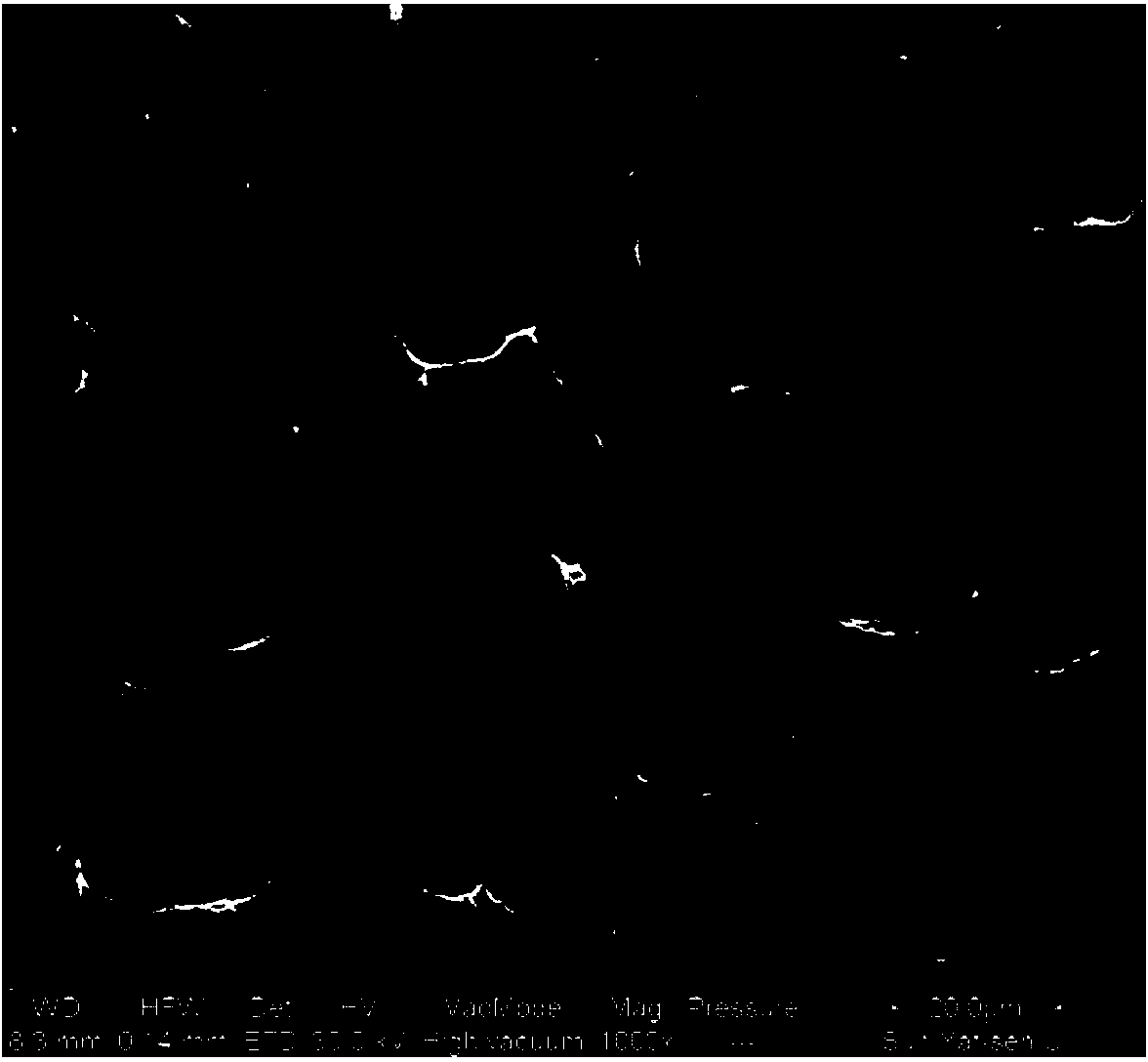

[0038] 2) Sand blasting treatment: the dental implant treated in step 1) is sprayed with aluminum oxide particles with a diameter of 120 μm under 0.45 MPa air pressure, the nozzle is 1 cm away from the pure titanium implant, and the nozzle is perpendicular to the dental implant and sprayed evenly for 30 seconds, so that The surface of the dental implant has uniform primary holes; then it is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes, and then dried naturally;

[0039] 3) Surface acid etching treatment: Mix 18% HCL and 49% H2SO4 with deionized water to mix the prepared hydrochloric acid and sulfuric acid at a volume ratio of 1:1, and completely immerse the dental implant a...

Embodiment 2

[0047] A dental implant, the surface of which is treated by:

[0048] 1) Cleaning of pure titanium dental implants: Ultrasonic cleaning of pure titanium dental implants with acetone, absolute ethanol, and deionized water for 10 minutes each, and natural drying;

[0049] 2) Sand blasting treatment: spray the dental implant treated in step 1) with aluminum oxide particles with a diameter of 100 μm under 0.45 MPa air pressure, spray the nozzle 0.5 cm away from the dental implant, and spray the nozzle perpendicular to the dental implant for 20 seconds, so that The surface of the dental implant has uniform primary pores; then it is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 minutes, and then dried naturally;

[0050] 3) Acid etching treatment on the surface of pure titanium implant: use deionized water to prepare 18% HCl, 49% H 2 SO 4 Mix the prepared hydrochloric acid and sulfuric acid at a volume ratio of 1:1, completely immerse the dental...

Embodiment 3

[0058] A dental implant, the surface of which is treated by:

[0059] 1) Cleaning of pure titanium dental implants: Ultrasonic cleaning of pure titanium dental implants with acetone, absolute ethanol, and deionized water for 20 minutes each, and natural drying;

[0060] 2) Sandblasting treatment: spray the dental implant treated in step 1) with aluminum oxide particles with a diameter of 150 μm under 0.45 MPa air pressure, spray the nozzle 1.5 cm away from the dental implant, and spray the nozzle perpendicular to the dental implant for 40 seconds, so that The surface of the dental implant has uniform primary holes; then it is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes, and then dried naturally;

[0061] 3) Surface acid etching treatment: Mix 18% HCL and 49% H2SO4 with deionized water to mix the prepared hydrochloric acid and sulfuric acid at a volume ratio of 1:1, and completely immerse the dental implant after step 2) in the bis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com