Method for manufacturing high-AR and fine-line PCB

A technology of fine lines and PCB boards, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of difficulty and inability to manufacture, and achieve the effect of reducing the thickness of surface copper, facilitating manufacture, and reducing the difficulty of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

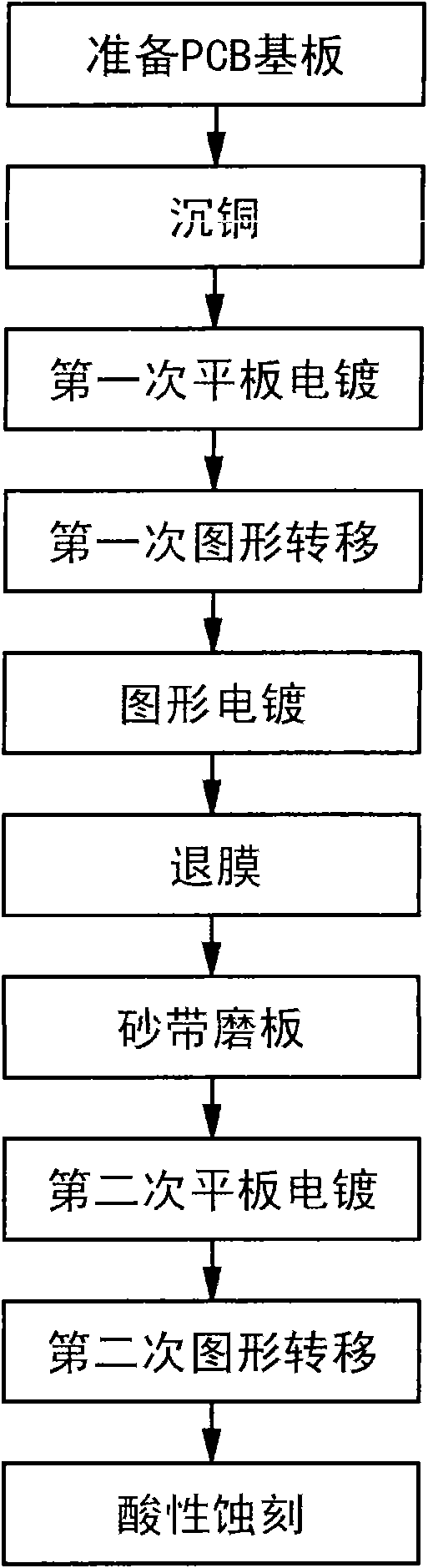

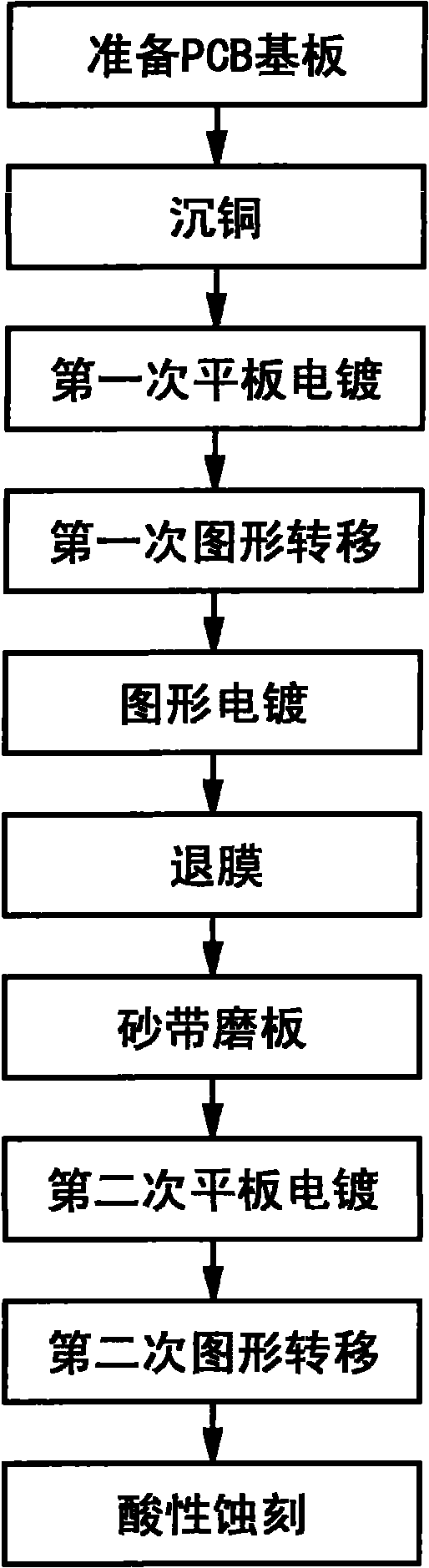

[0024] As shown in the accompanying drawings, the manufacturing method of high thickness-to-diameter ratio and fine circuit PCB board in this preferred embodiment includes the following steps:

[0025] (1) Prepare the PCB substrate: metallized holes are provided on the above PCB substrate;

[0026] (2) Copper sinking: perform copper sinking treatment on the PCB substrate according to the conventional copper sinking process;

[0027] (3) The first flat plate electroplating: The PCB substrate after the copper sinking treatment is immersed in the electroplating solution for electroplating. The surface copper thickness and the hole copper thickness of the first flat plate electroplating are both between 5 μm and 8 μm; the first flat plate The current density of electroplating is 1.2ASD, and the electroplating time is 21MIN;

[0028] The surface copper thickness and hole copper thickness of 5μm-8μm above can withstand various treatments in the subsequent manufacturing process;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com