Self-etch amphiphilic dental adhesive and preparation method thereof

An adhesive and amphiphilic technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of difficult infiltration of adhesives, poor bonding effect, poor bonding strength effect, etc., and achieve high bonding. Strength, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment relates to a self-etching amphiphilic adhesive.

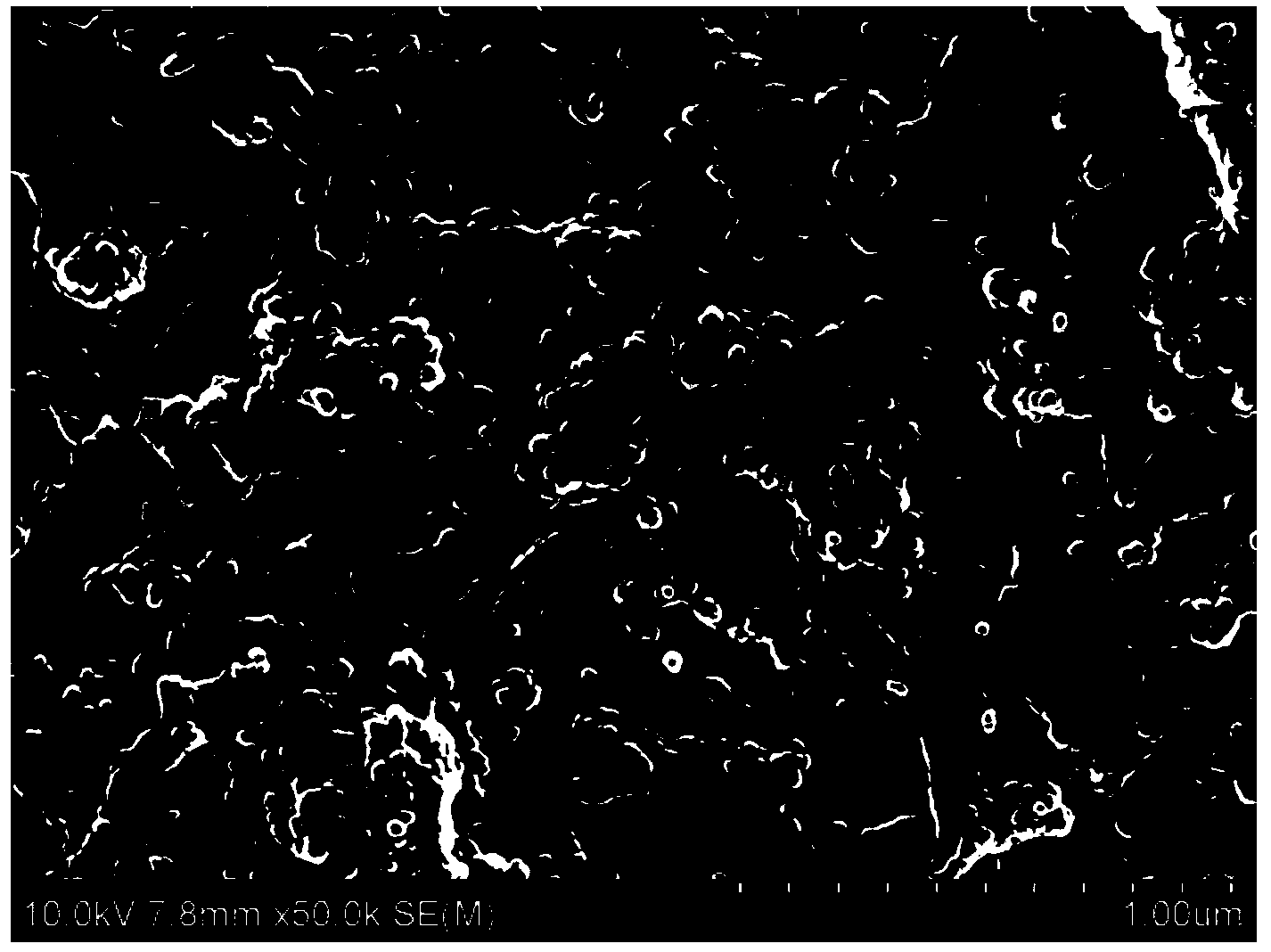

[0045] 1.1. HEMA (hydroxyethyl methacrylate) surface modification of silica

[0046] Weigh a certain amount of nano-silica powder and slowly add it into the ethanol solution (ethanol: water = 19: 1, mass ratio), stir evenly, move it into a three-necked flask, and stir it quickly with a magnetic stirrer. After the dispersion is complete, drop Add 12% silane coupling agent APTES (3-aminopropyltriethoxysilane), after the dropwise addition, gradually raise the temperature to 110°C, reflux with a condenser tube, continue stirring for 3h, and after cooling down to room temperature, use Ethanol and water were subjected to several centrifugal washings and dried to obtain amino-modified silica a.

[0047] Add HEMA to 50mL dimethyl sulfoxide (DMSO), the molar ratio of HEMA to APTES is 1:1, after complete dissolution, add NHS (N-hydroxysuccinimide) and EDC (1- Ethyl-3-(3-dimethylaminopropyl)-carbodiimide) and TEA ...

Embodiment 2

[0052] This embodiment relates to a self-etching amphiphilic adhesive. It is prepared as follows:

[0053] According to the ratio of 1.5, Bis-GMA (bisphenol A diglycidyl methacrylate) was dissolved in TEGDMA (triethylene glycol dimethacrylate) at 60°C, and stirred for more than 30 minutes to make it uniform Solution, cool the solution, and then mix HEMA (dihydroxyethyl methacrylate) and MEP (di[2-(methacryloyloxy) ethyl] phosphate) according to the ratio of 2:95 and 3:95 respectively Join in the above solution, stir, then add photoinitiator CQ (camphorquinone) by 0.4% of the total mass of each monomer mixed solution above, add DMAMA (2 -(dimethylamino)ethyl methacrylate), add BHT (2,6-di-tert-butyl-4-methylphenol) according to 0.1% of the total mass of the above monomer mixed solution, stir evenly, and then Add the HEMA-modified silica obtained in Example 1 according to 10% of the total mass of the above monomer mixed solution, stir for 6 hours, make it mix evenly, keep away...

Embodiment 3

[0055] This embodiment relates to a self-etching amphiphilic adhesive.

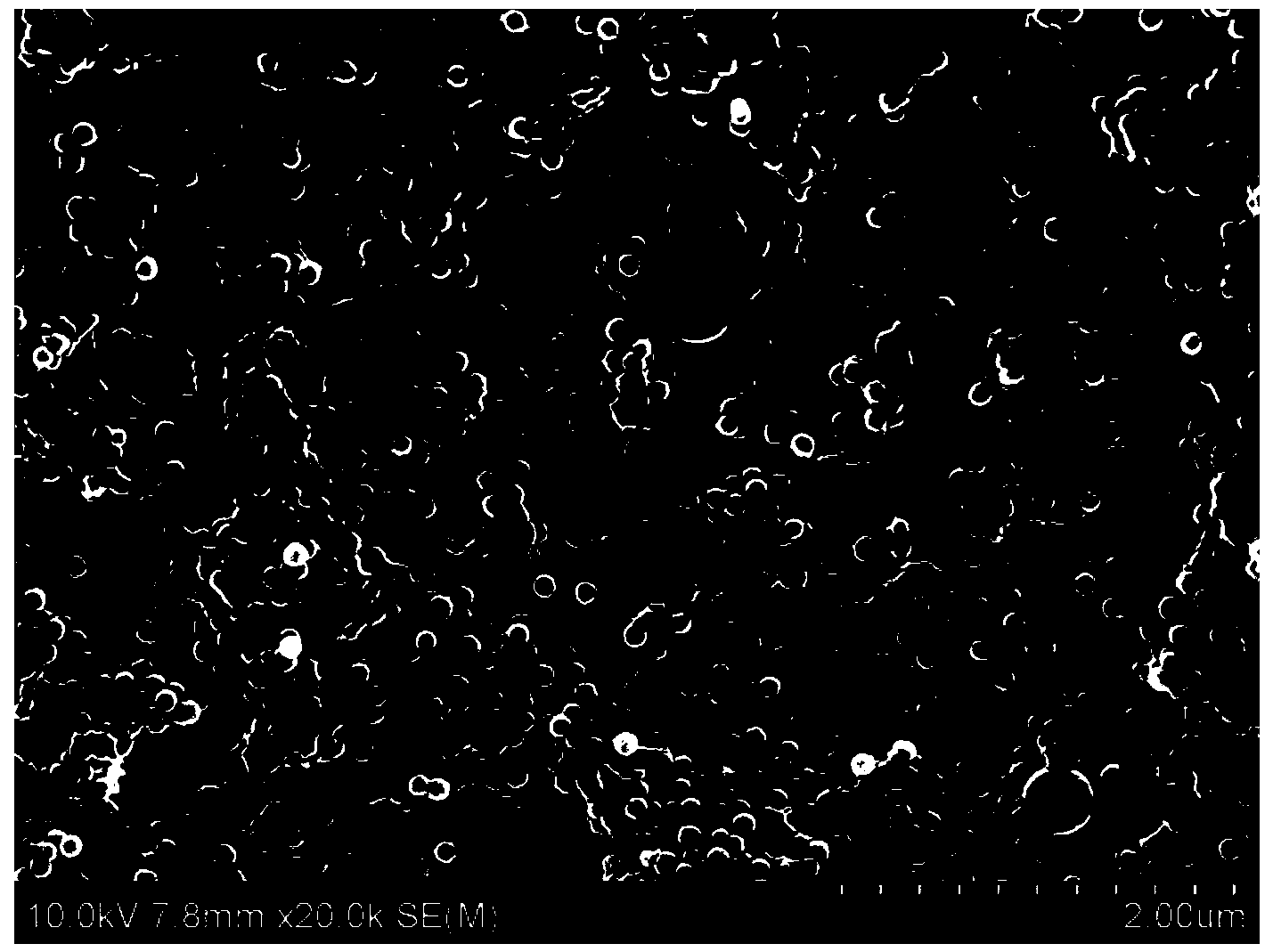

[0056] 3.1. Acrylic anhydride modification of POSS (octapolycage silsesquioxane)

[0057] Get a certain amount of amino-modified POSS, put into a four-necked flask equipped with a reflux condenser, add 8 times its molar amount of acrylic anhydride to it, then add the solvent of triethylamine and dimethylformamide to it, then in N 2 Under protection, the product was obtained after heating and stirring at 80°C for 24 hours, and then the product was dispersed in ether, centrifuged for 6 times, placed in a vacuum oven, and dried at room temperature for 24 hours to obtain acrylamide-modified POSS.

[0058] 3.2. Preparation of self-etching amphiphilic binder

[0059] According to the ratio of 1.5, Bis-GMA (bisphenol A diglycidyl methacrylate) was dissolved in TEGDMA (triethylene glycol dimethacrylate) at 60°C, and stirred for more than 30 minutes to make it uniform Solution, cool the solution, and then mix H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com