Recycling and regenerating process method and metal copper recovery system of acid chloride etching solution

A technology of recycling and process method, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of not being able to be put into industrial use, safe production of toxic gas leakage, and complicated equipment, etc., to achieve strong practicability and safety Circular work, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

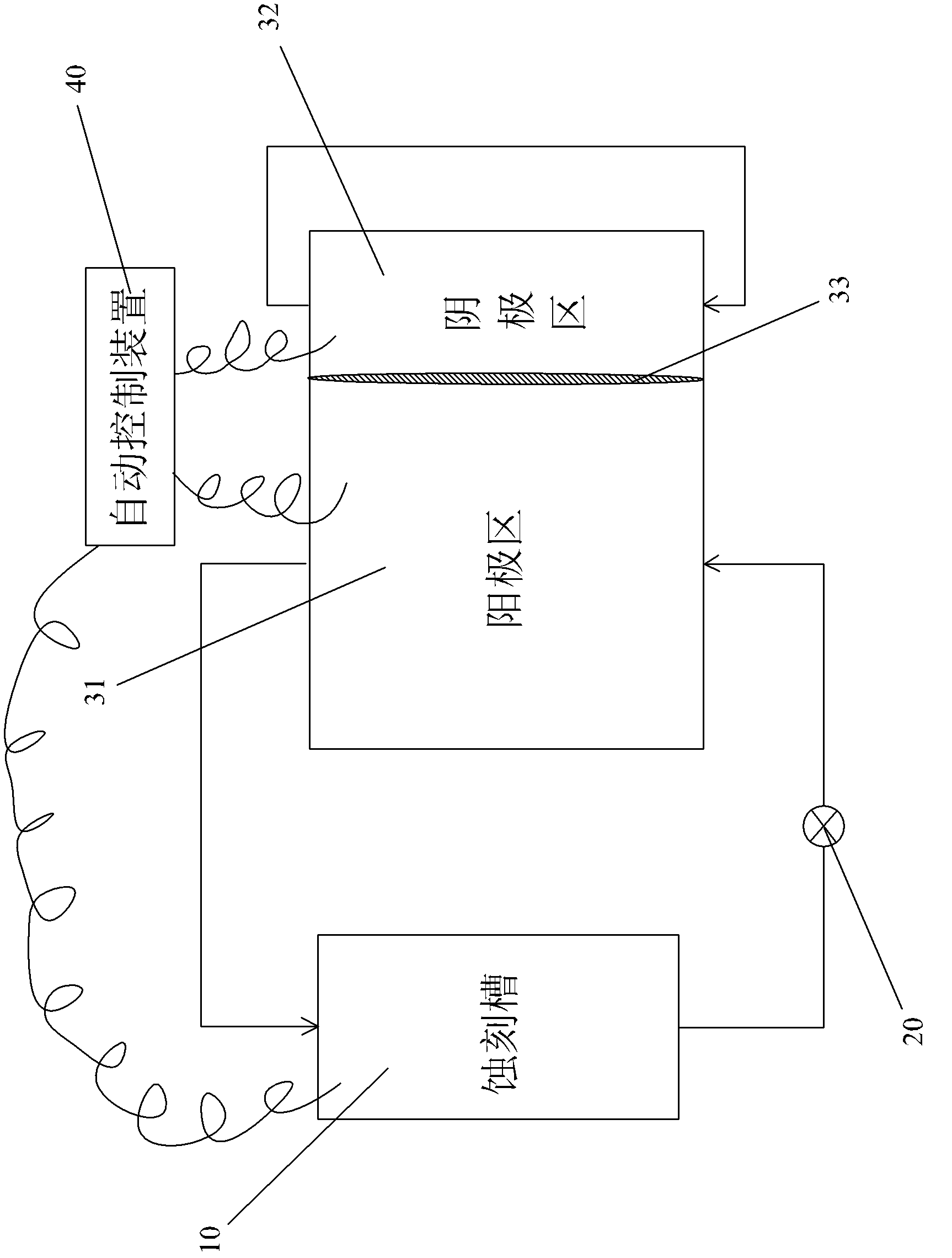

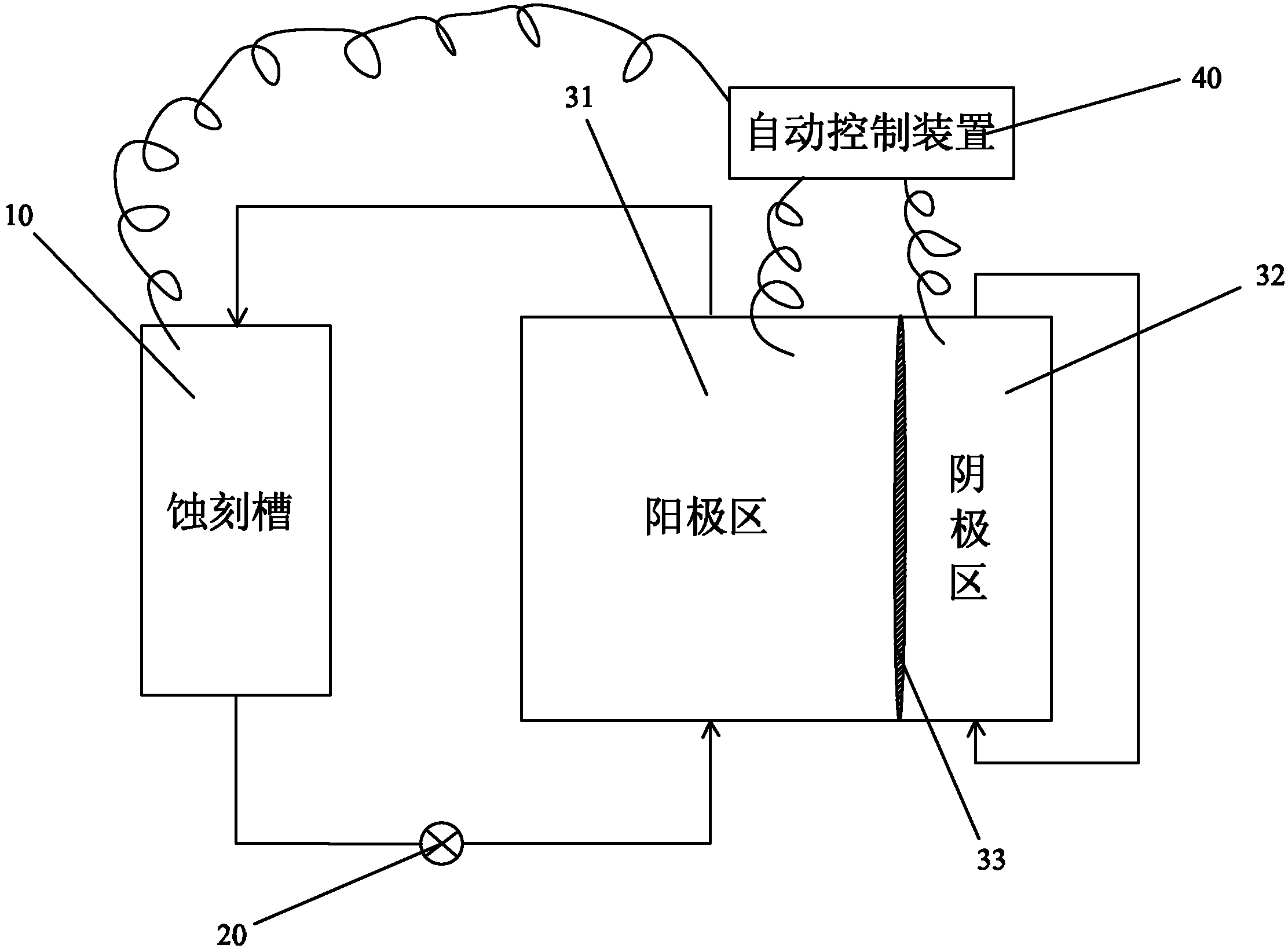

Method used

Image

Examples

Embodiment 1

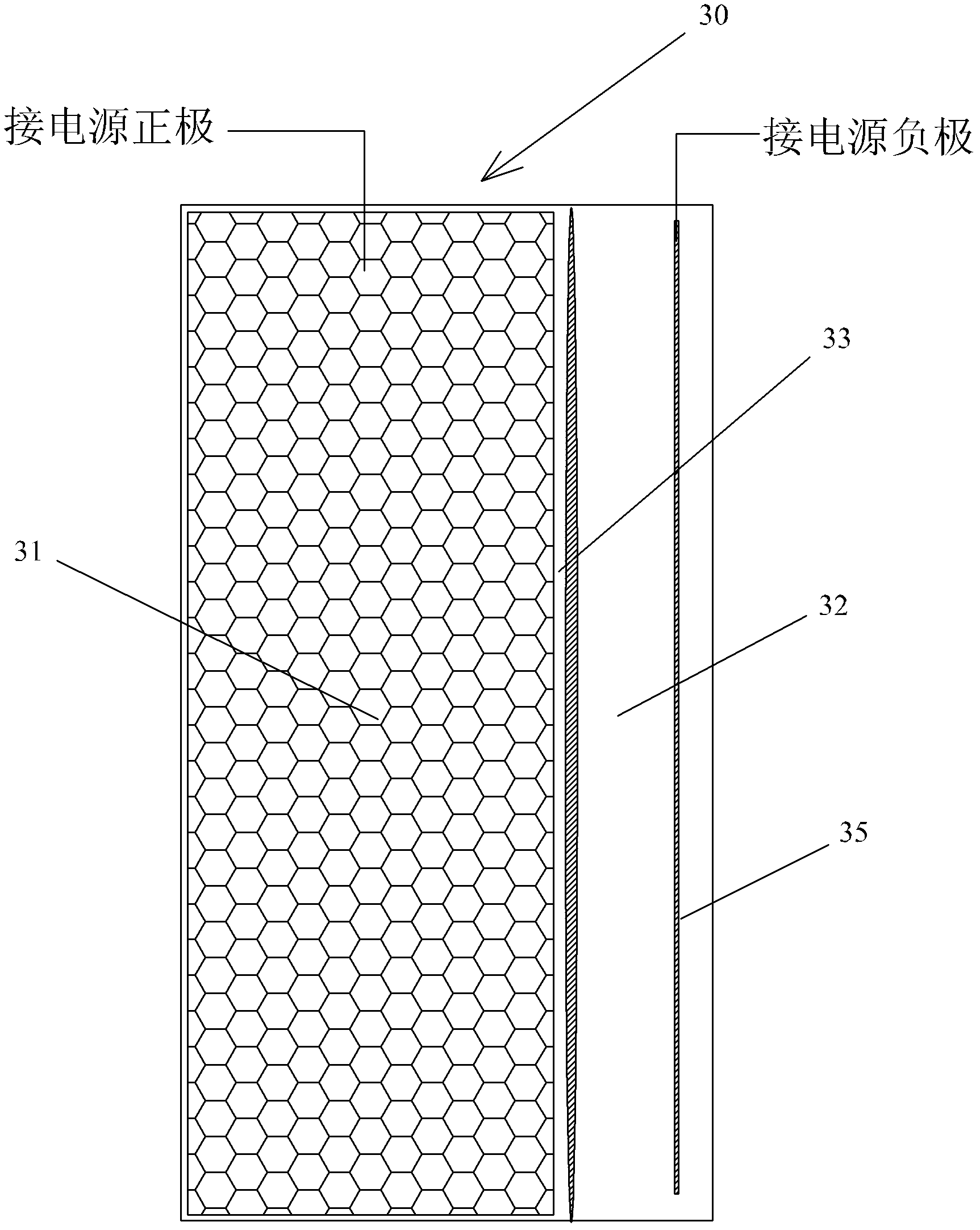

[0059] 200 liters of etching solution, including copper ions 166.5g / l, acidity 1.3N, chloride ions 278g / l, ORP 511mv;

[0060] Regenerative membrane electrolyzer equipment: the anode plate adopts graphite anode, immersion design, the isolation membrane adopts DuPont Nafion perfluorosulfonic acid cation exchange membrane; the cathode plate adopts pure titanium plate, the concentration of sulfuric acid in the cathode solution is 8%, and the copper ion is 40g / l;

[0061] The operating temperature is 48°C. When the power is turned on for electrolysis operation, there is no gas precipitation in the anode area and no peculiar smell. The copper ion of the etching solution regenerated by electrolysis is 158.8g / l, the acidity is 1.3N, the chloride ion concentration is 277.5g / l, the ORP is 565mv, the accumulated electrolysis electricity is 1380Ah, and the copper deposited on the cathode plate weighs 1535.6g.

Embodiment 2

[0063] Etching production line site: The volume of the etching tank is 500 liters, the control range of copper ions is 150-165g / l, the acidity is 1.0-1.5N, the ORP is controlled at 510-540mv; the working temperature of the etching solution is 50+ / -2°C.

[0064] Regenerative membrane electrolyzer equipment, the anode plate adopts graphite anode, immersed flow design, the isolation membrane adopts DuPont Nafion perfluorosulfonic acid cation exchange membrane; the cathode plate adopts pure titanium plate, the sulfuric acid concentration of the cathode solution is 10%, and the copper ion is 45g / l;

[0065] The automatic control system works stably. During the electrolysis process, there is no gas precipitation in the anode area, and there is no peculiar smell on site; during the quantitative test, the accumulated electrolysis power is 10860Ah, and the theoretical copper deposition weight per Ah on the cathode plate is 12289.9g. 1185g, thus calculating its Faraday DC electrolysis ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com