Test device and method for simulating acid etching crack flow guide capability

A technology of conductivity and testing equipment, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc. It can solve problems such as unsatisfactory coring, too long rock sample size, acid fluid loss, etc., and achieve measurement The method is practical, the principle is reliable, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

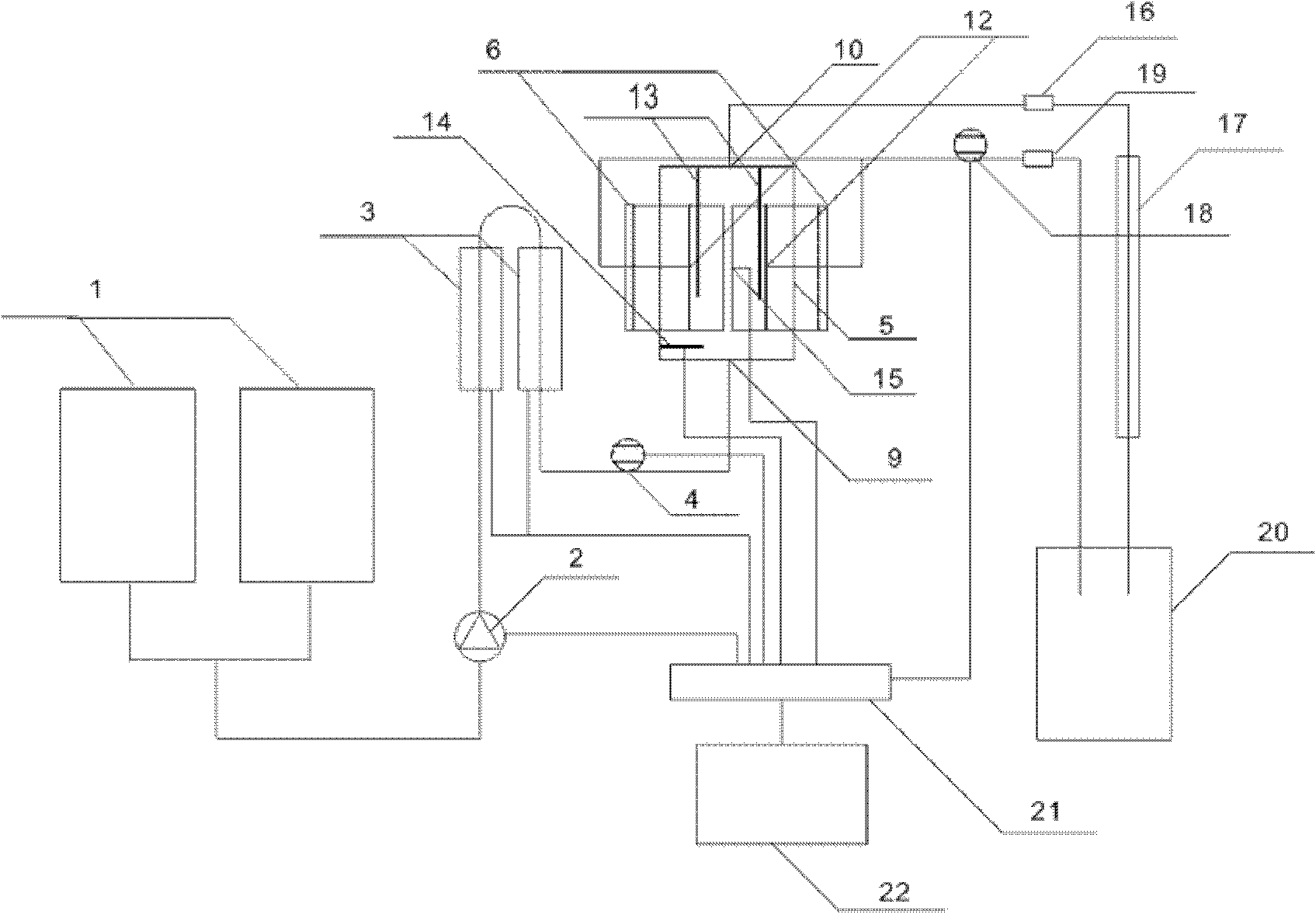

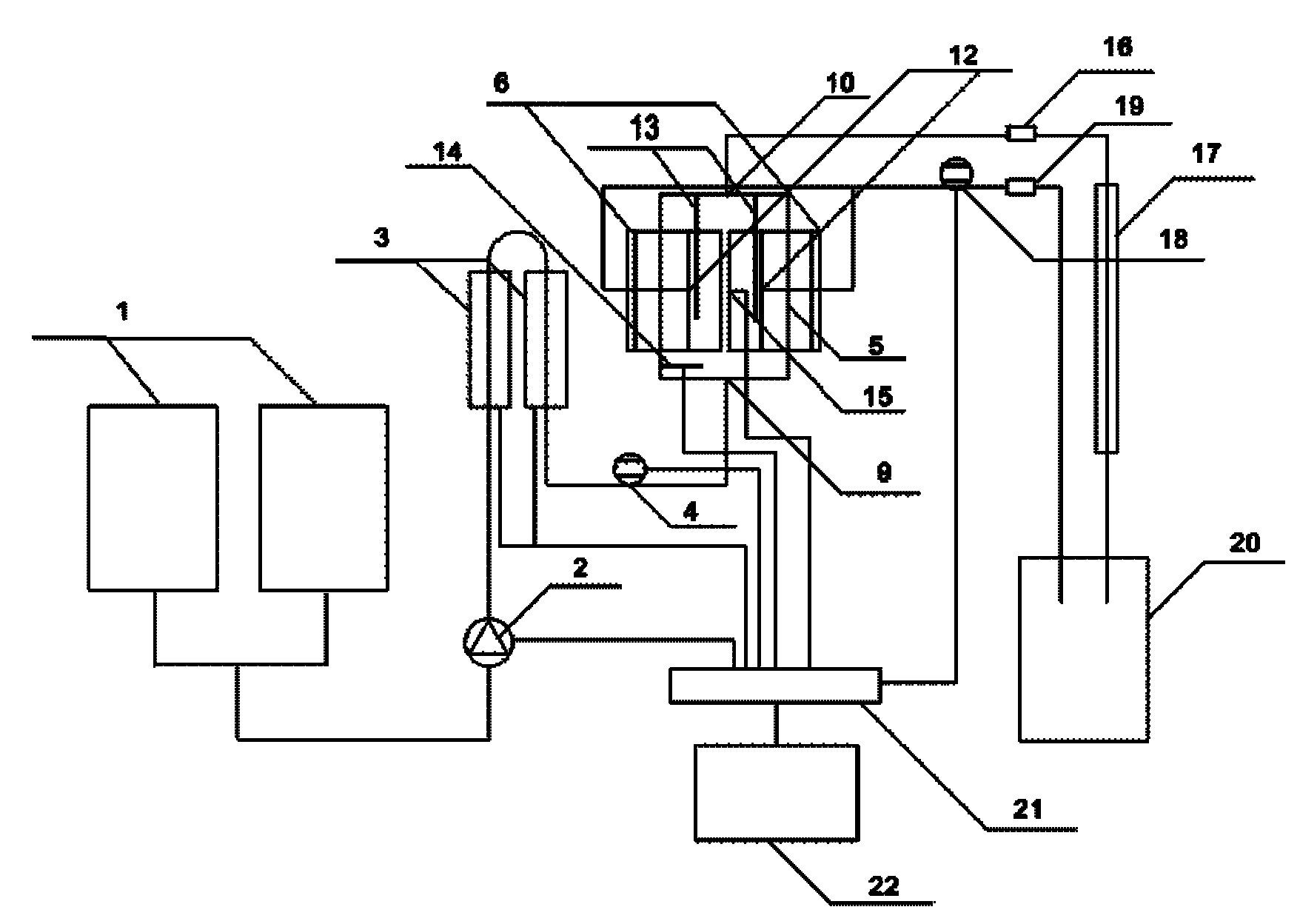

[0031] Further illustrate the present invention according to accompanying drawing below.

[0032] see figure 1 , figure 2 .

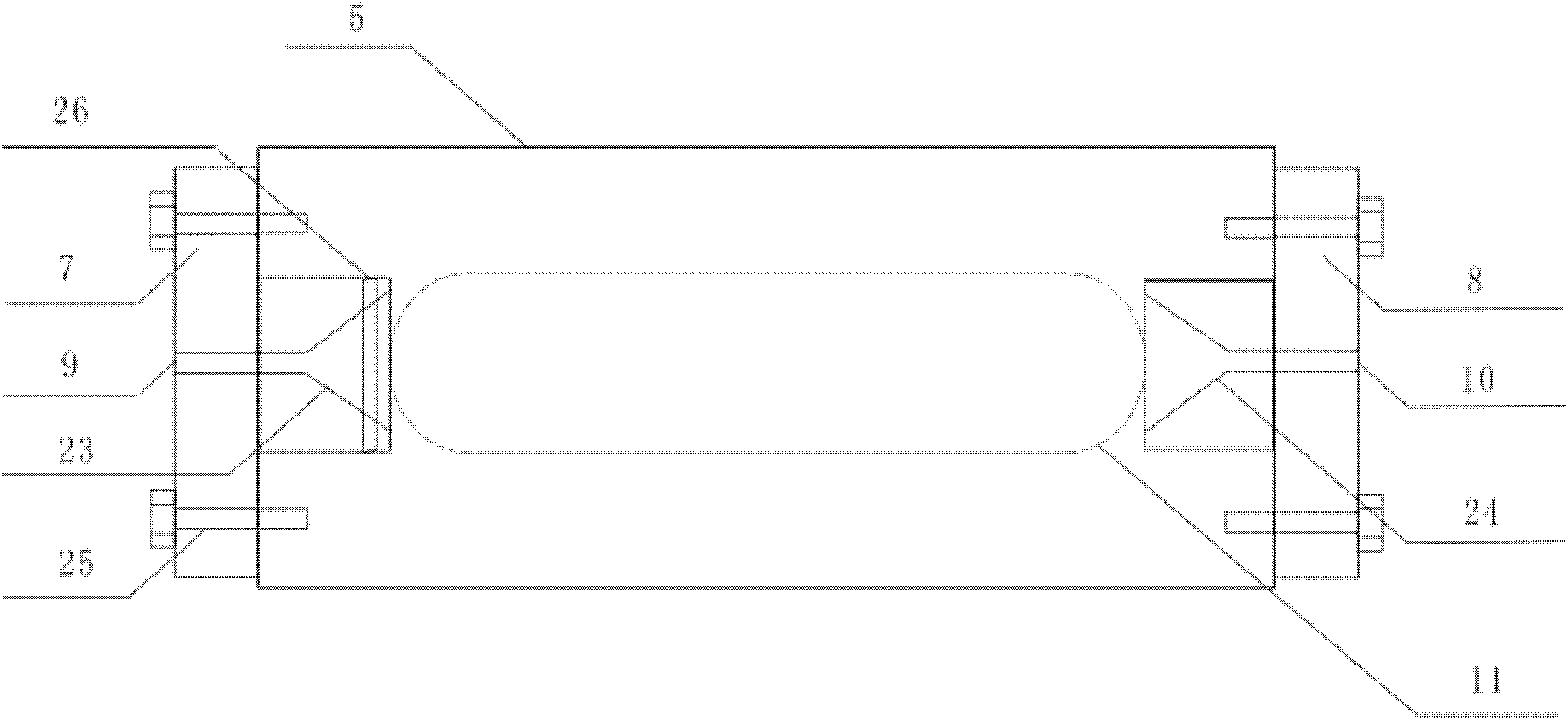

[0033] A test device for simulating the conductivity of acid-etched cracks, mainly composed of a liquid storage tank 1, a diaphragm pump 2, a pipeline electric heating jacket 3, flow meters 4 and 18, a plate holder 5, back pressure valves 16 and 19, Condenser pipe 17, waste liquid tank 20, data acquisition and control board 21, computer 22, press machine 6 are formed. There are deep holes inside the plate holder for inserting electric heating rods 13, temperature sensors 14 and pressure sensors 15; both ends of the plate holder have liquid inlet holes 9 and liquid outlet holes 10 respectively, and the liquid inlet The small holes are connected with flowmeter 4, electric heating jacket 3, diaphragm pump 2 and liquid storage tank 1 in sequence, and the small holes for liquid outlet are connected with back pressure valve 16, condensation pipe 17 and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com