Micro-angle-adjustable anti-rotation tool

A technology of anti-rotation and tools, which is applied in the direction of manufacturing tools, hand-held tools, threaded fasteners, etc. It can solve the problems that the position of the edge of the nut or bolt cannot be calibrated, it cannot be flexibly used in multiple places, and it is laborious to remove or install the bolt. , to avoid the inconvenience of support, to choose flexibly, and to ensure the effect of tightening torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

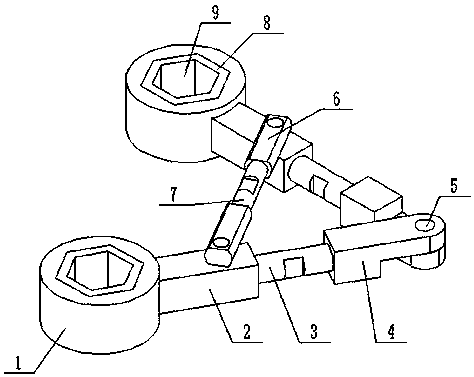

[0024] Such as figure 1 As shown, a fine-tuning angle anti-rotation tool includes two positioning blocks 1, and two positioning blocks 1 are provided with limit holes 9, and the limit holes 9 are used to limit the rotation of nuts or bolts to be disassembled. Connecting handles 2 are arranged on the top, and the other ends of the two connecting handles 2 are all provided with lockable telescopic rods 3, and the other ends of the two telescopic rods 3 are all provided with connectors 4. Both ends of the rod are threadedly connected to the connecting handle 2 and the connecting head 4 respectively, and the other ends of the two connecting heads 4 are hinged through the rotating shaft 5, and a mounting hole is also provided on the two connecting handles 2;

[0025] Also includes a positioning handle, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com