Ultra-high strength strip steel and its production process

A production method and ultra-high-strength technology, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of no slow cooling section, low cooling speed, slow cooling speed, etc., to reduce production costs, excellent mechanical properties, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

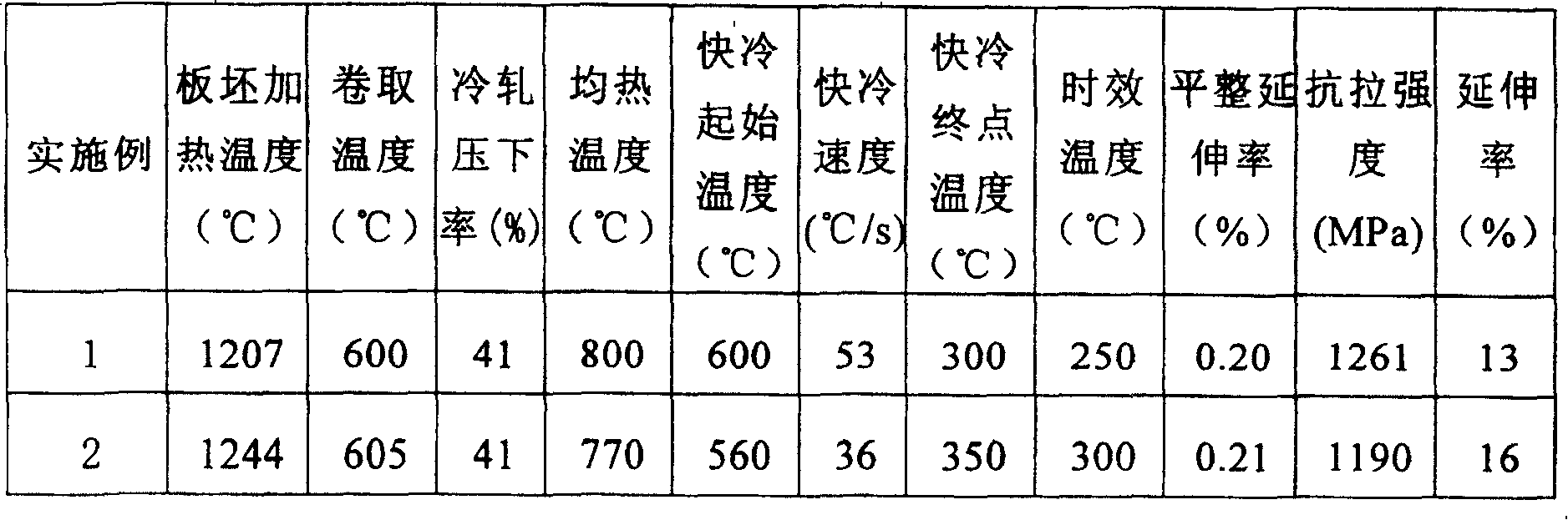

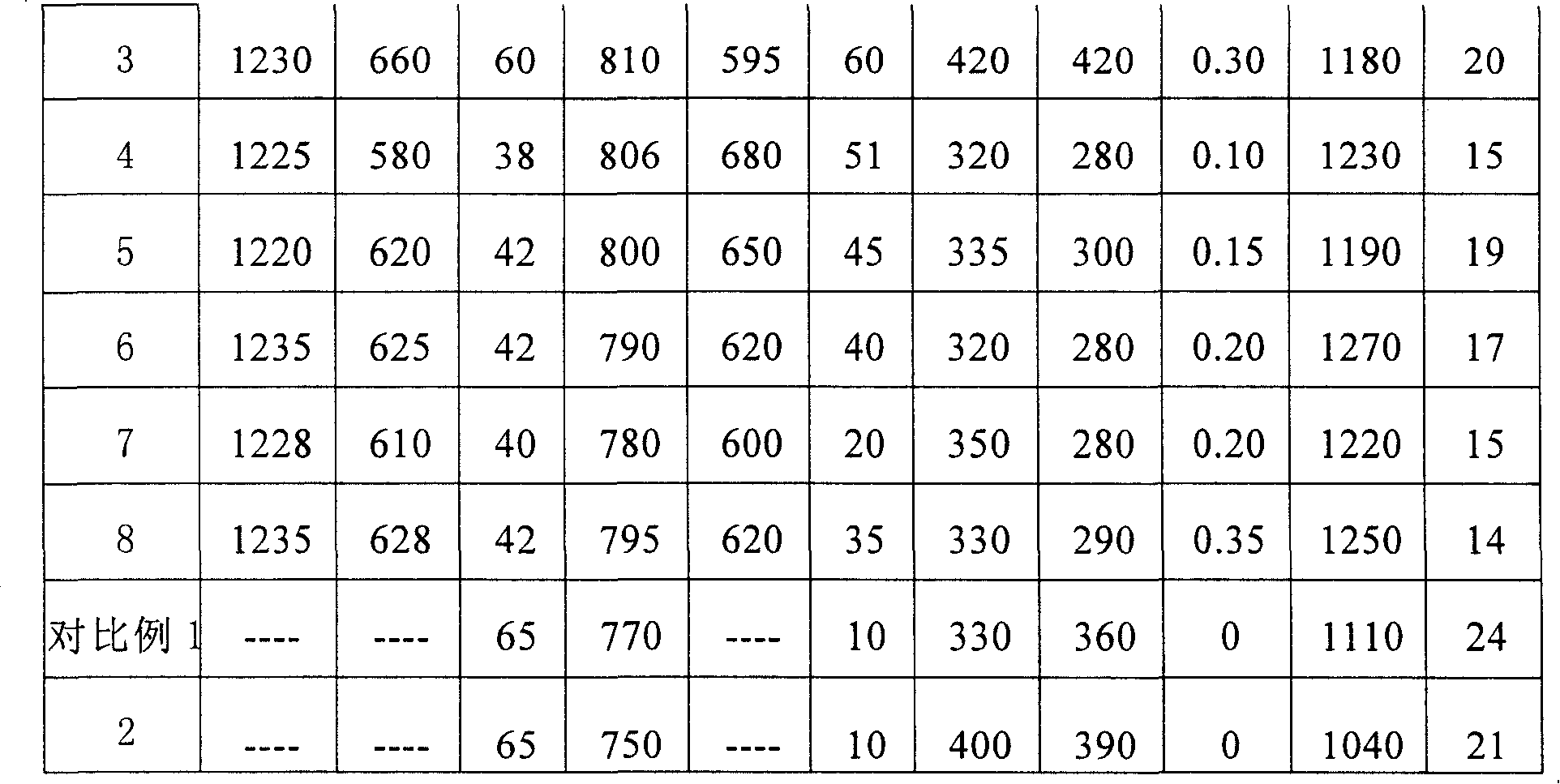

[0041] The present invention will be further described through Examples 1-8 according to the differences in the chemical composition, hot rolling, cold rolling, continuous annealing and tempering process parameters of the invented ultra-high strength steel strip.

[0042] The chemical composition of molten steel is shown in Table 1, and the balance is Fe and unavoidable impurity elements.

[0043] Table 1 embodiment and the chemical composition of comparative patent

[0044] Example

C

Si

mn

Al

Cr

Nb

Ti

B

N

P

S

1

0.15

0.5

2.5

0.04

0.50

0.025

0.015

0.0008

0.004

0.015

0.003

2

0.15

0.5

2.5

0.04

0.50

0.025

0.015

0.0008

0.004

0.015

0.003

3

0.18

0.4

2.2

0.02

0.35

0.030

0.030

0.0018

0.003

0.018

0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com