Pattern atmosphere lamp and method for manufacturing pattern atmosphere lamp

A technology of ambient lights and patterns, applied in the field of automotive interiors, can solve the problems of high processing requirements for light-transmitting panels, low surface hardness of light-transmitting panels, and high production difficulty, to meet mass industrial production, improve scratch resistance and The effect of wear resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

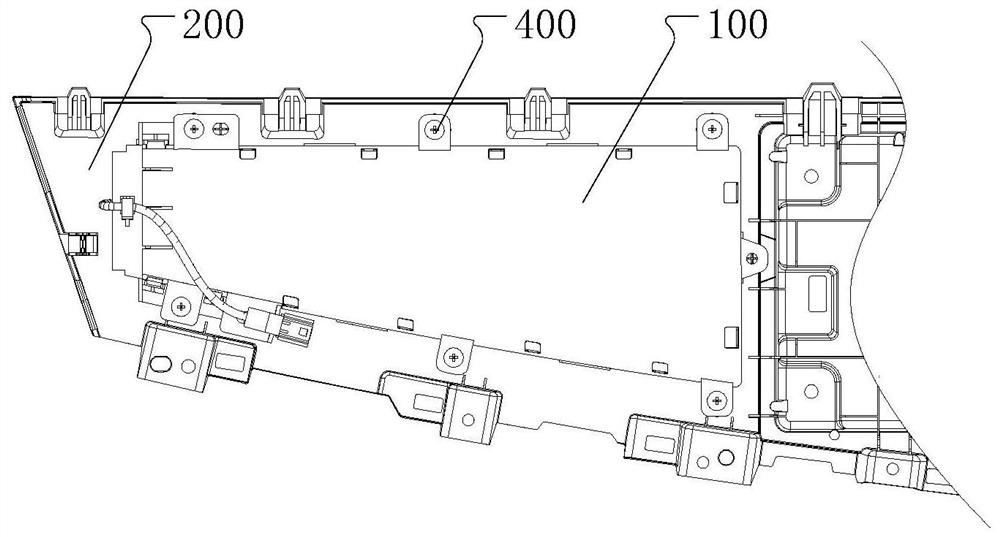

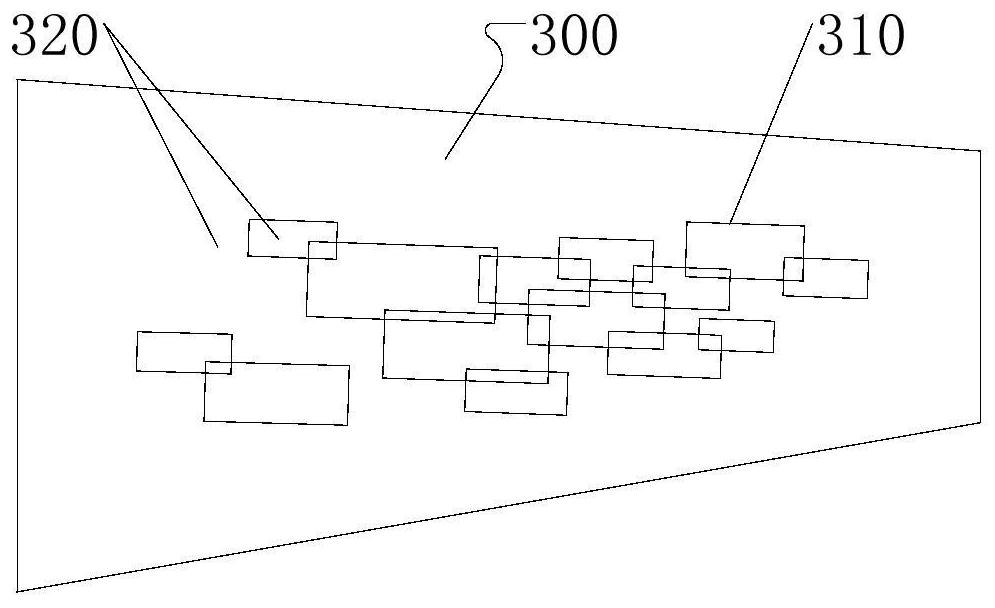

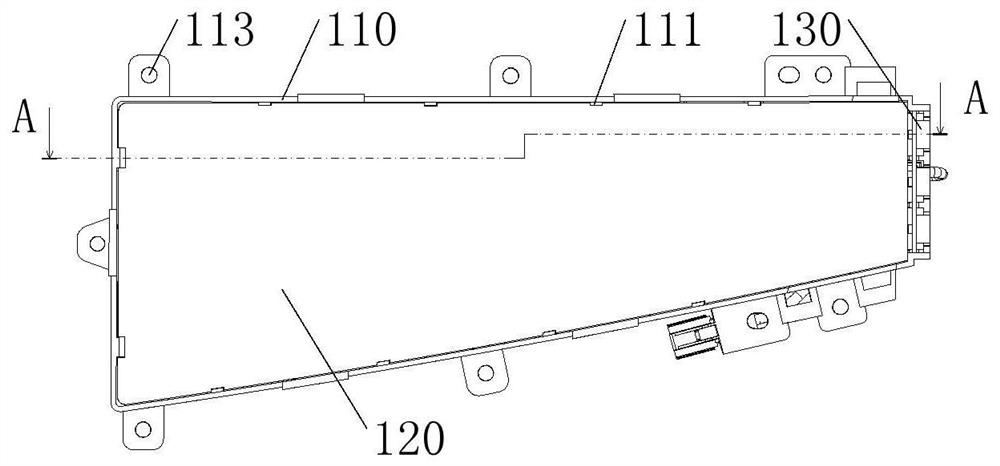

[0049] Such as figure 1 As shown in -4, a patterned ambient light includes an ambient light body 100 and a mounting panel 200. The ambient light body 100 is fixed and installed on the inner side of the mounting panel 200 by screws 400. When the ambient light body 100 is turned on, the light generated can pass through the The installation panel 200 is irradiated outward; and, a diaphragm 300 with a patterned light-transmitting function is arranged on the surface of the installation panel 200, and the atmosphere lamp body 100 is set opposite to the diaphragm 300, so that the atmosphere lamp body can be used as the atmosphere lamp body at night. After the 100 is turned on, the light passes through the installation panel 200 and the diaphragm 300 in turn, and under the action of the diaphragm 300, the effect of pattern light transmission is produced, thereby improving the quality of the car interior and improving the visual effect; during the day, the atmosphere The lamp body is i...

Embodiment 2

[0063] Based on the patterned atmosphere lamp involved in the first embodiment above, this embodiment provides a manufacturing method for the patterned ambient lamp, as follows: Figure 5 As shown, it includes the following steps:

[0064] The diaphragm needs to be designed and developed according to the specific modeling pattern;

[0065] The first step is film printing. The transparent ink and non-transparent ink are printed on the surface of the film substrate in a way of offset printing. The light can pass through the printed transparent ink, but not the non-transparent ink. , in this way, the light will only be transmitted from the position where the transparent ink is printed, and since the transparent ink is in the form of a pattern, the light will produce the effect of pattern transmission when it is transmitted from the transparent ink;

[0066] The second step is the vacuum forming of the diaphragm. This process mainly uses vacuum suction to heat and soften some the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com