Scale removing brush

A technology for descaling boxes and brushes, which is applied to workpiece surface treatment equipment, grinding machines, metal rolling, etc. It can solve the problems of reduced service life of descaling system components, lack of good solutions, and affecting product surface quality. Achieve the effects of increasing service life, reducing maintenance workload, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

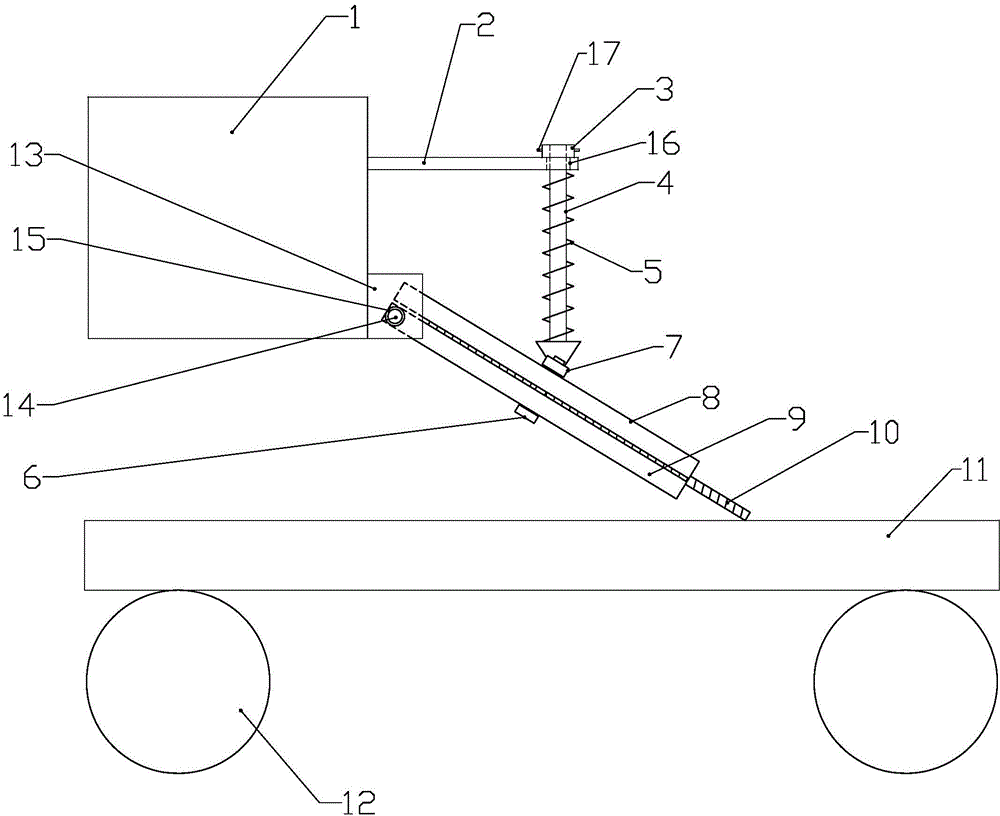

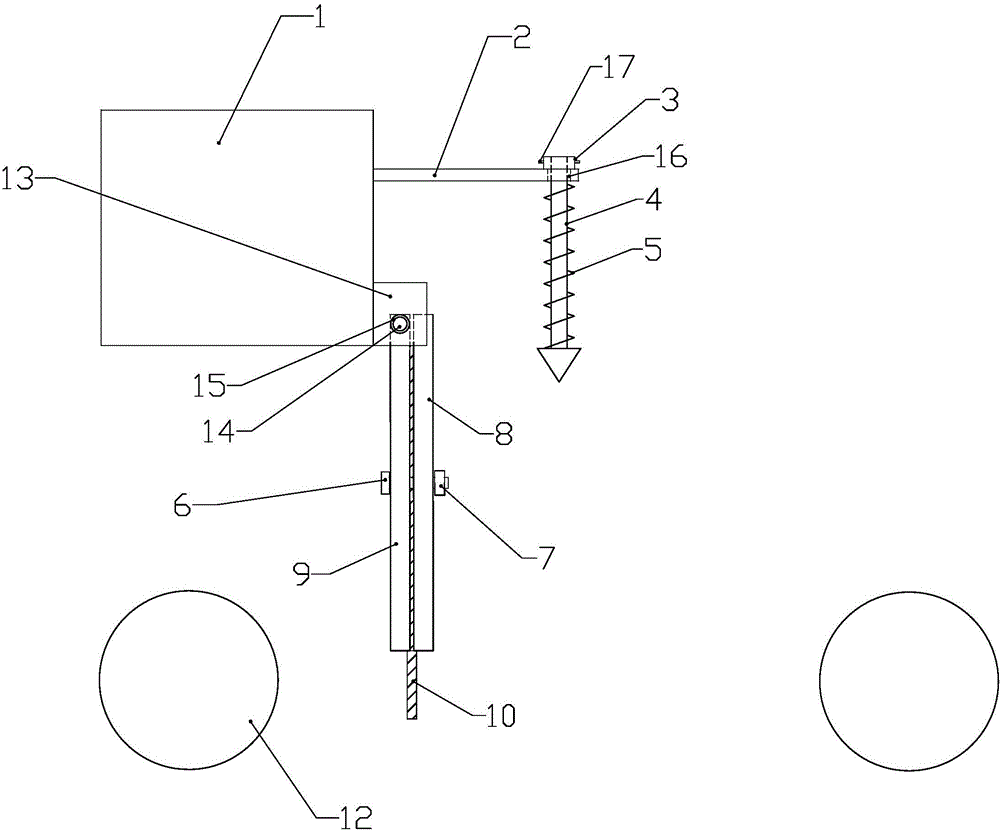

[0012] Refer to the attached figure 1 And attached figure 2 The descaling brush of the present invention will be described in detail below.

[0013] The structure of the descaling brush of the present invention comprises a brush body and a spring pressing rod 4, the described brush body is arranged on the outer wall of the descaling box 1, the described spring pressing rod 4 is arranged on the upper part of the brush body, and the described brush body The body includes a first steel plate 8, a second steel plate 9 and a steel wire rope 10, the first steel plate 8 is arranged on the upper part of the second steel plate 9, the first steel plate 8 and the second steel plate 9 are clamped by the steel plate clamping bolt 6 and the steel plate The nuts 7 are connected, and the steel plate clamping bolts 6 are respectively arranged on both sides of the first steel plate 8 and the second steel plate 9, and are fastened by the steel plate clamping nuts 7. The first steel plate 8 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com