Film-stripping method and film-stripping mechanism therewith

A technology of manipulators and protective films, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as easily damaged product surfaces, and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

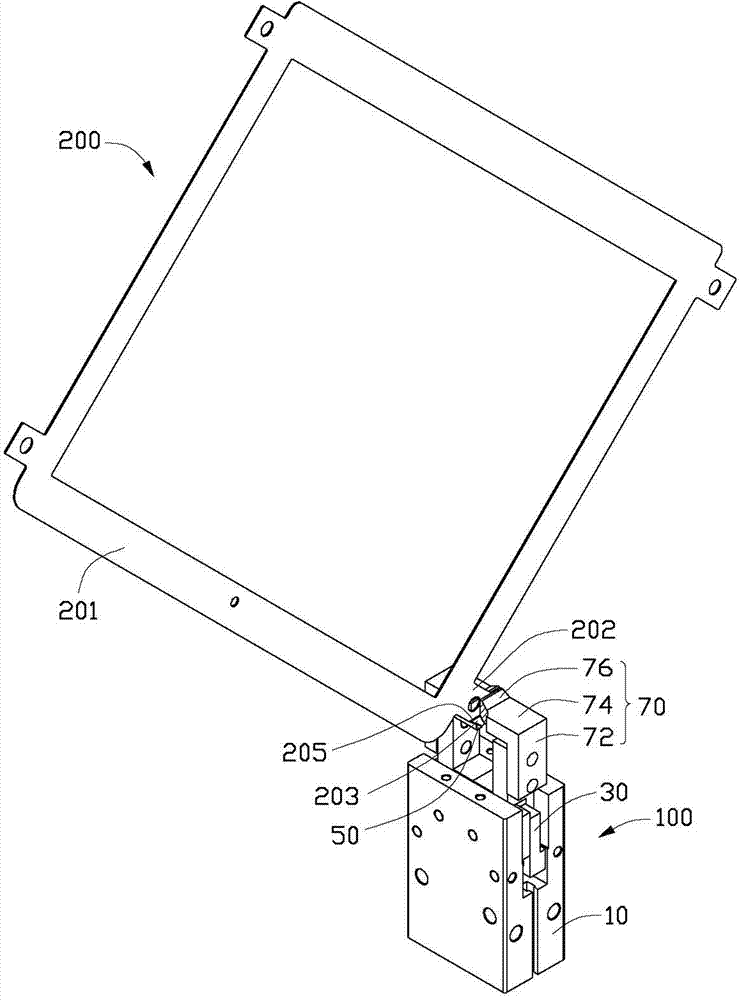

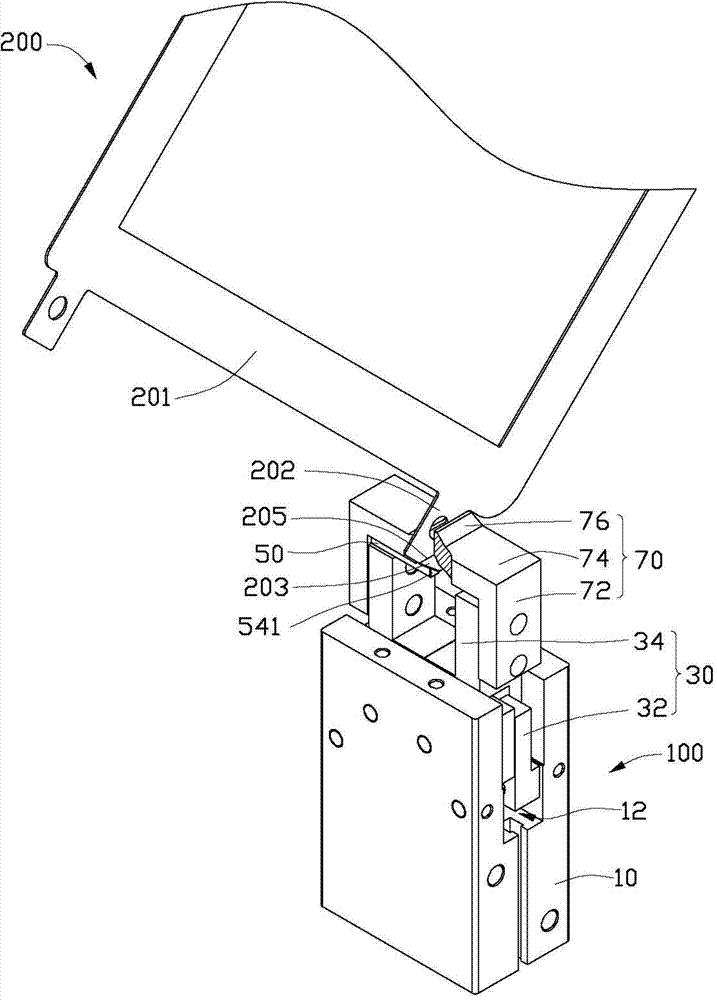

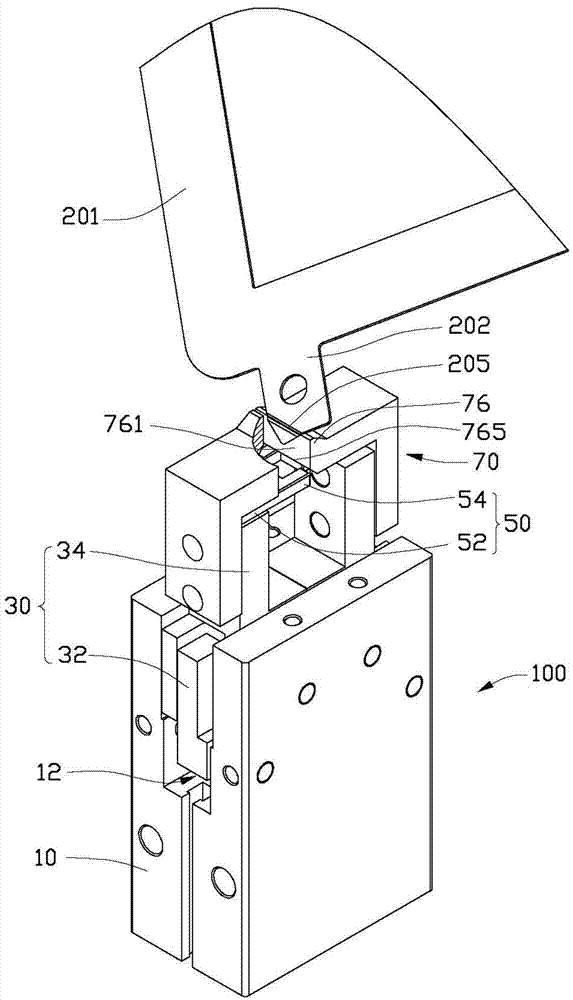

[0031] see Figure 1 to Figure 3 , in the film tearing method according to the first embodiment of the present invention, the film tearing mechanism 100 is used in cooperation with a manipulator (not shown) to tear off the protective film (not shown) on the surface of the sheet-shaped workpiece 200 . The film tearing mechanism 100 includes a fixing base 10 , a driving element 30 disposed on the fixing base 10 , and two shearing elements 50 and two clamping elements 70 disposed on the driving element 30 .

[0032] The fixing seat 10 is substantially in the shape of a rectangular block, and an accommodating space 12 is formed at one end thereof for accommodating the driving member 30 .

[0033] Please also refer to Figure 4 The driver 30 is mounted on the fixing seat 10 and accommodated in the receiving space 12 , and includes a driving body 32 and a mounting portion 34 connected to the driving body 32 . The driving body 32 is fixed on the fixing seat 10 and accommodated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com