A quick way to remove 3D printing supports

A 3D printing and fast technology, applied in the field of additive manufacturing, can solve problems such as residual stress of parts, difficulty in removing supports, and deformation of parts, and achieve the effect of less media material consumption, easy and fast removal of supports, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

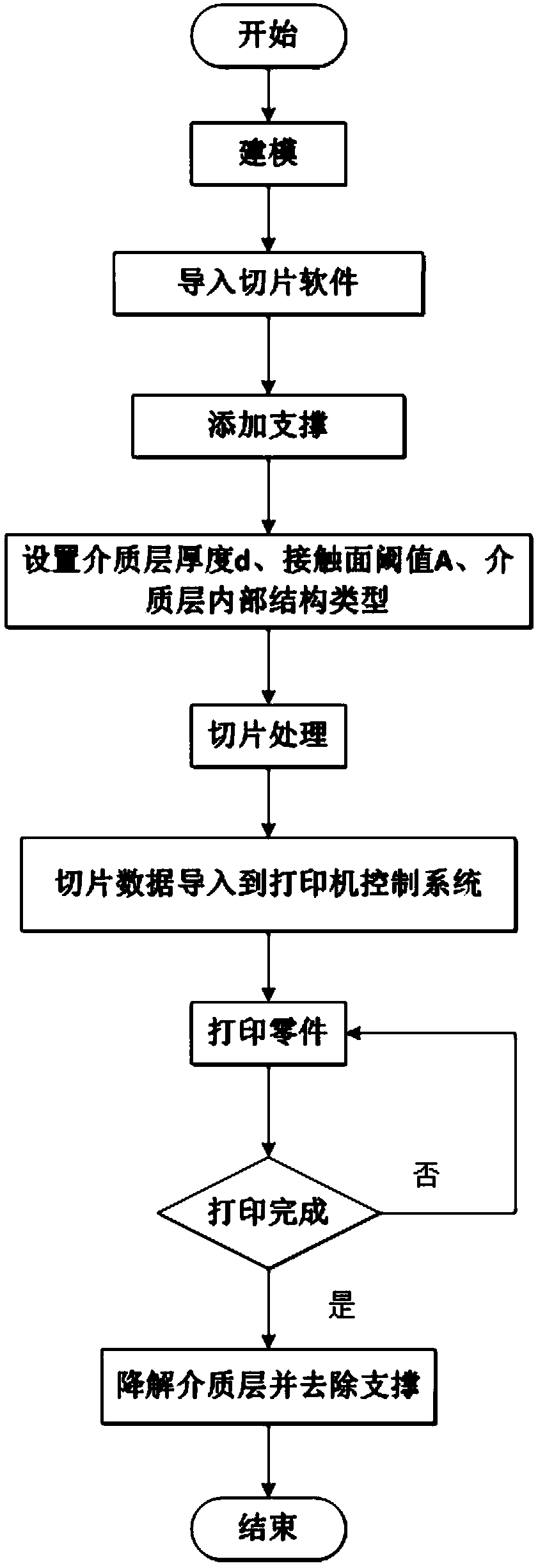

[0044] A method for quickly removing a 3D printing support of the present invention comprises the following steps:

[0045] (1) Use 3D software to build part models and save them in .STL format;

[0046] (2) Import the part model saved in the .STL format into the slicing software to add support and slice;

[0047] (3) Identify and separate the slice information of parts and supports in step (2), extract the slice information of the start and end of supports and save them to the control system;

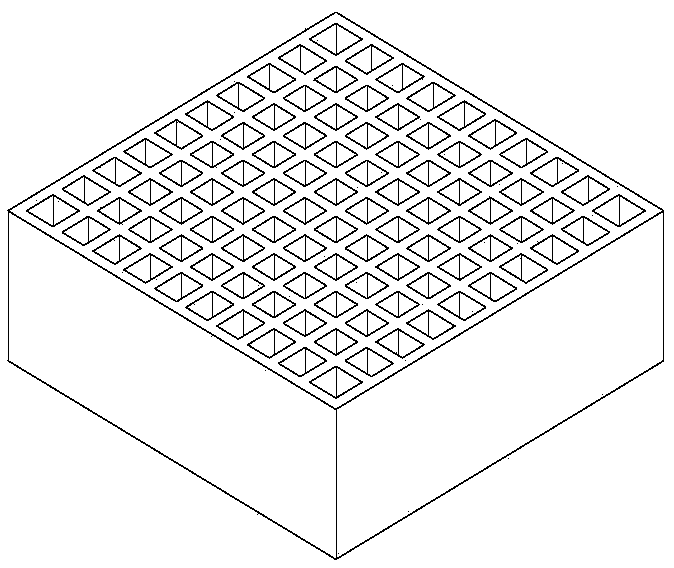

[0048] (4) Before the printing of the support structure starts, the control system controls the media material nozzle to print a layer of media material on the substrate or the pre-formed part entit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com