Novel hole sealing tank liquid for aluminum alloy oxidation section and sealing method by using the same

A sealing groove, oxidation technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as affecting the surface quality, achieve good sealing effect and improve sealing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 2

[0031] Add 50 grams of nickel carbonate, 5 grams of chromium fluoride, 50 grams of sodium dodecyl sulfonate and 180 grams of sodium methylene bisbenzyl naphthalene sulfonate into 50 ml of dilute acetic acid solution, stirring while adding until the salt Completely dissolve to obtain a high-concentration sealing bath; then continue to add water to the sealing bath until nickel ions are diluted to 0.5g / L-5g / L and chromium fluoride is diluted to 0.2g / L.

[0032] In this embodiment, by increasing the content of the surfactant, the adsorption capacity of the sealing bath can be effectively improved, and the sealing bath can be directly adsorbed on the surface of the workpiece by spraying.

preparation Embodiment 3

[0034] Add 50 grams of nickel acetate, 5 grams of chromium fluoride, 50 grams of sodium dodecylsulfonate, a mixture of 200 grams of methylnaphthalenesulfonate formaldehyde polycondensate and sodium naphthalene methylenesulfonate to 50ml of dilute acetic acid solution Stir while adding until the salts are completely dissolved to obtain a high-concentration sealing bath; then continue to add water to the sealing bath until the nickel ions are diluted to 0.5g / L-5g / L, and the chromium fluoride is diluted to 0.08g / L.

Embodiment 1

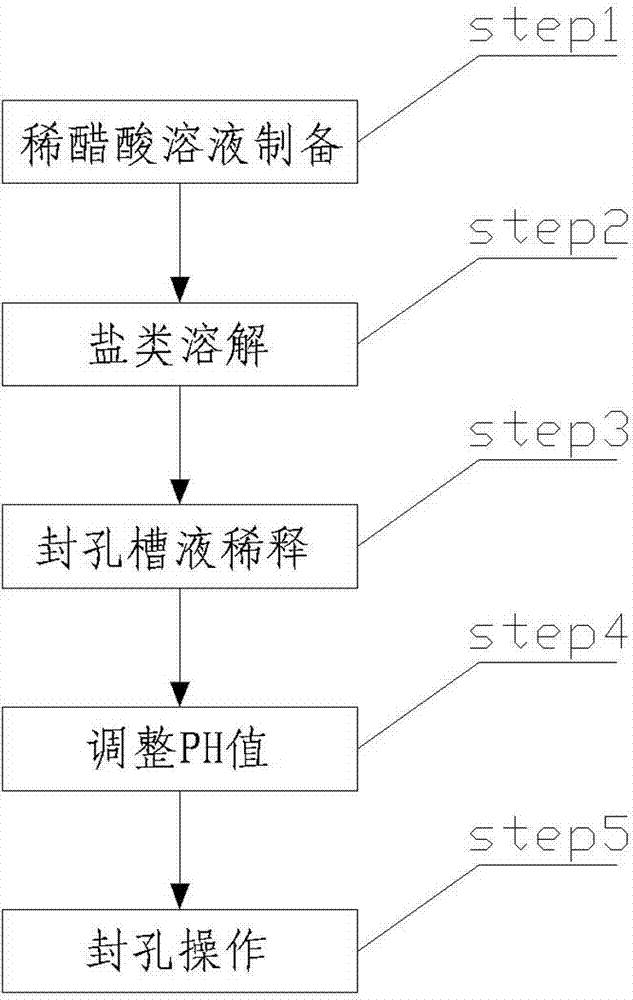

[0036] Such as figure 1 As shown, a method for sealing holes of aluminum alloy oxidized profiles, the specific steps include: the first step (step 1) preparation of dilute acetic acid solution, adding acetic acid dropwise to an acid-resistant tank filled with water to obtain dilute acetic acid solution.

[0037] The second step step2 is to dissolve the salt, slowly add nickel fluoride and chromium fluoride into the dilute acetic acid solution according to the weight to volume ratio, and stir while adding until the nickel fluoride and chromium fluoride are completely dissolved.

[0038] The third step step3 is to dilute the sealing bath solution, and continue to add water to the nickel fluoride solution until the nickel ions are diluted to 0.5g / L-1.5g / L, and the chromium fluoride is diluted to 0.1g / L.

[0039] The fourth step step4 is to adjust the pH value, and gradually add ammonia water to the bath to adjust the pH value to between 5-7;

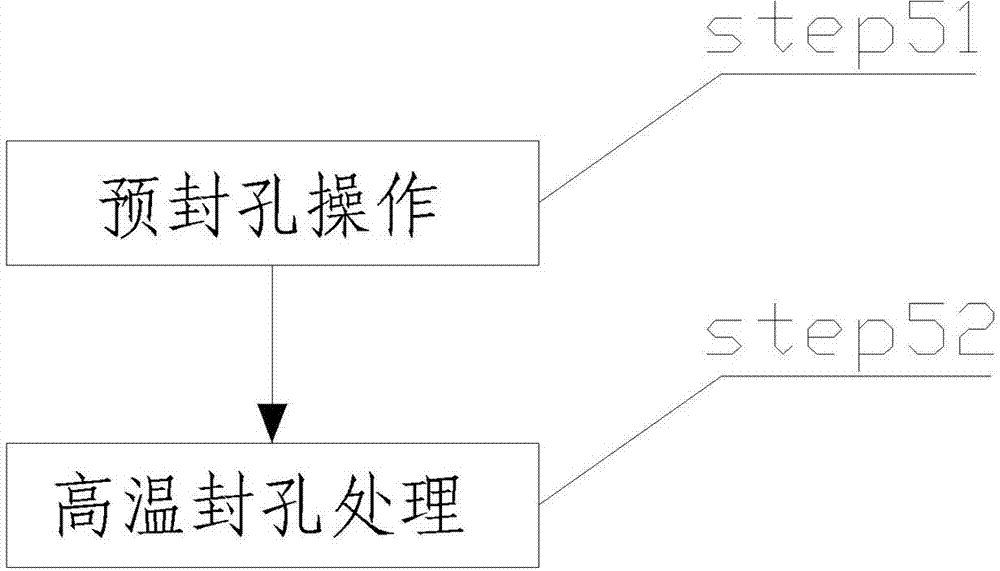

[0040] The fifth step step5 is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com