Anti-adhesion punch for powder molding

A powder forming and anti-adhesion technology, applied in manufacturing tools, presses, etc., can solve the problems of affecting product quality, decreasing use effect, increasing the cost of manufactured products, etc., to achieve easy installation and maintenance, reduce costs, and prevent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

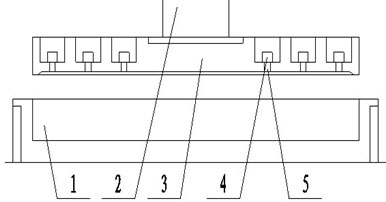

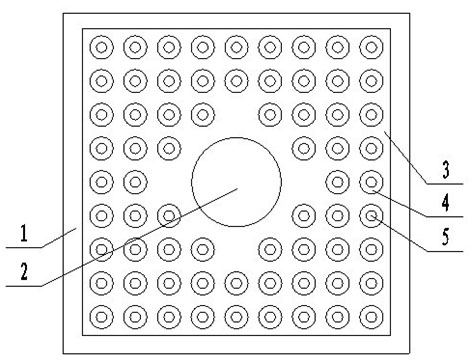

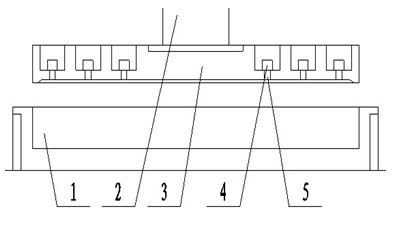

[0009] The powder forming anti-adhesion punch designed in the present invention (referred to as the punch, see figure 1 , 2 ), which is characterized in that small air holes (or air blowing holes) 5 are vertically evenly distributed on the punch 3, and each small air hole 5 is matched with a vent pipe 4, and the vent pipe 4 is connected to the The peripheral air compressor (not shown in the figure) is directly connected. The diameter and quantity of the small air holes 5 are determined according to the technological requirements of the shape, size and air film pressure of the punch.

[0010] The diameter of the small air hole 5 of the punch of the present invention is 2-4mm. If the diameter of the small air hole 5 is too large, it is not conducive to the formation of an air film, and it will also increase the power and operating cost of the air compressor; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com