Wall-adhered jet seal pressure stabilizing device in galvanized strip steel alloying process and application method thereof

A wall-attached jet and voltage stabilizing device technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of jet gas kinetic energy decrease, jet gas velocity decrease, jet gas quality increase, etc. Achieve continuous and effective operation, achieve thermal insulation requirements, and achieve simple and reliable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

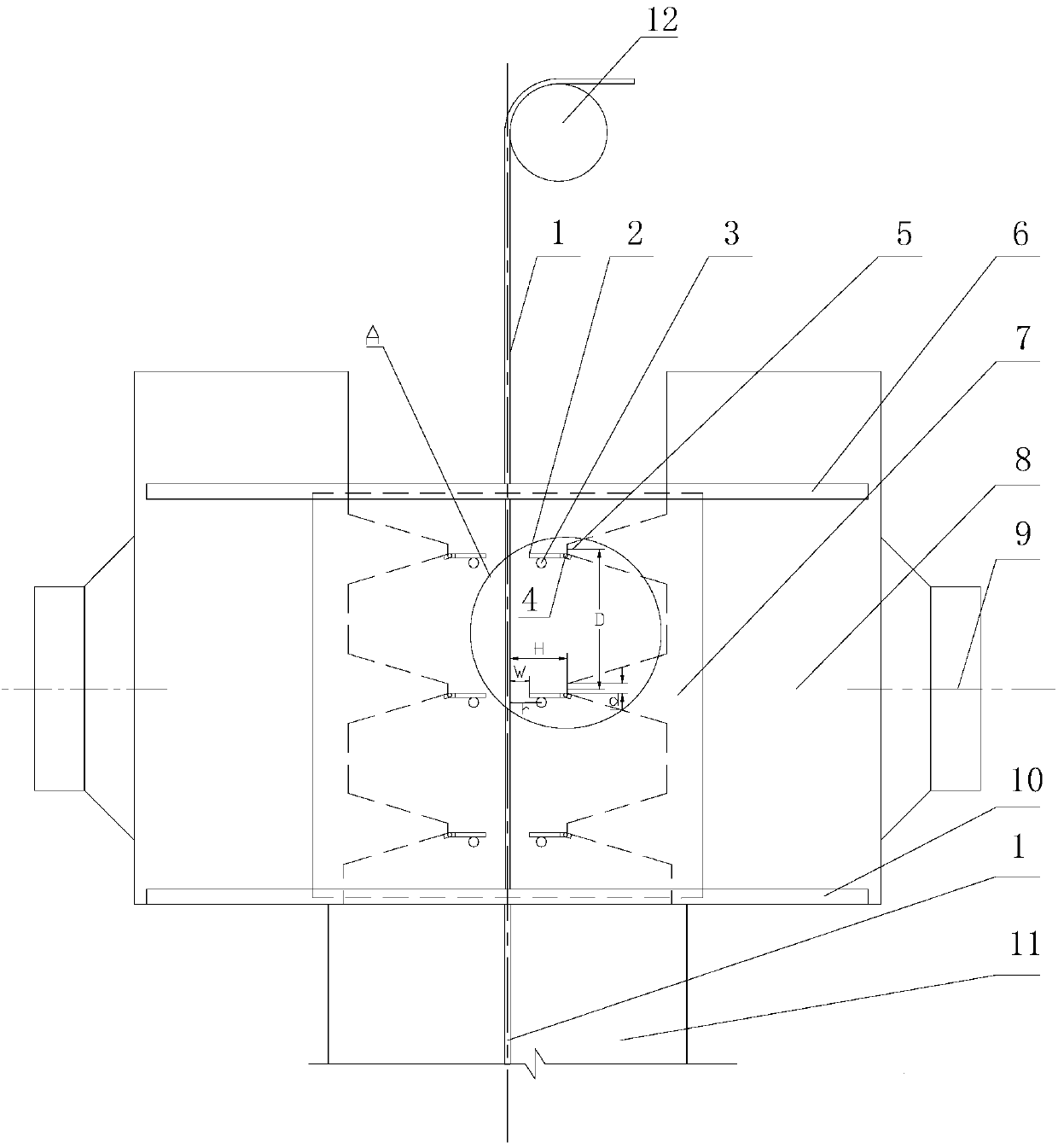

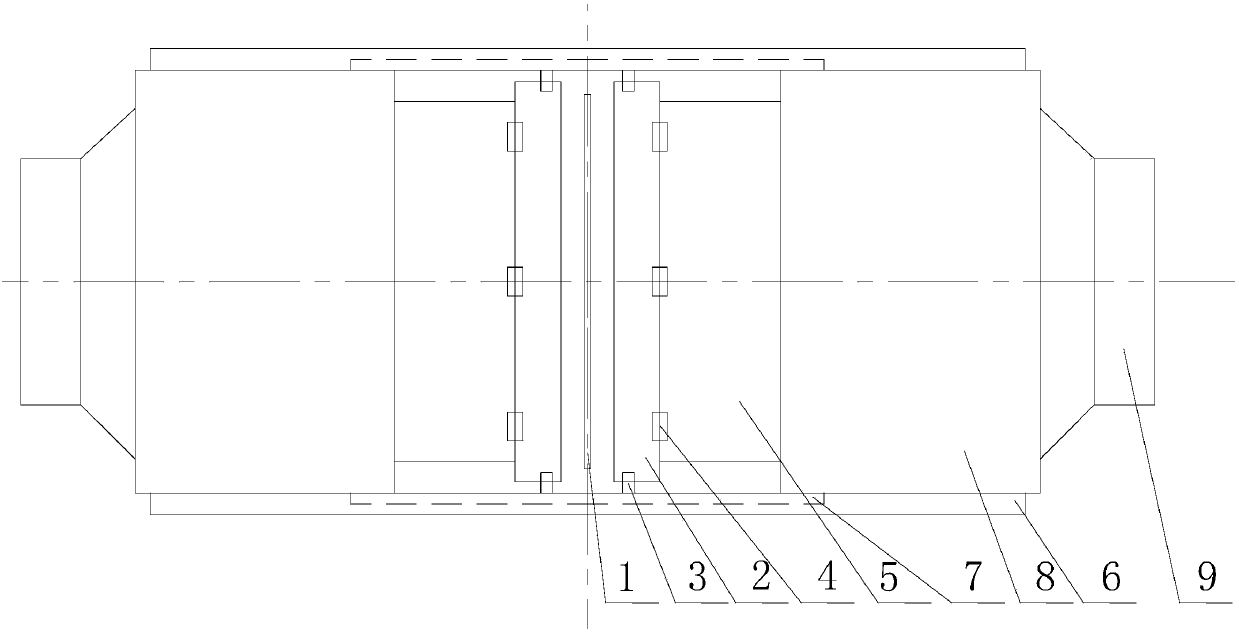

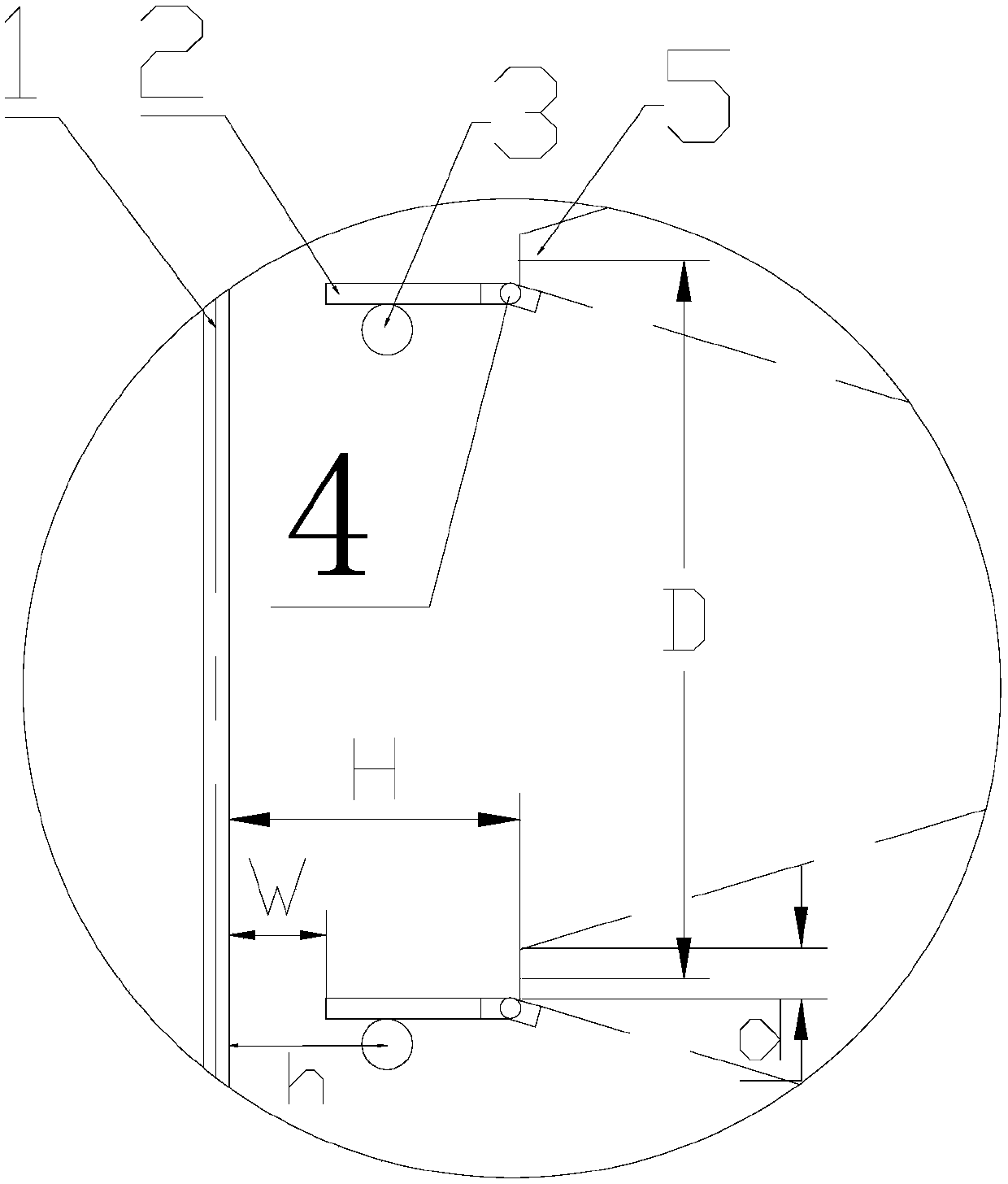

[0034] A wall-attached jet sealing pressure stabilizing device in the alloying process of galvanized strip steel, the device mainly consists of a bellows 8, a nozzle 5, a movable side plate 7, a spoiler 2, a supporting column 3, an upper slide 6, and a slide 10 Etc composition, galvanized steel strip width 1000mm.

[0035] like Figure 1~3, the galvanized steel strip passes through the heat preservation section 11 through the steering roller 12 and the bellows 8 on the left and right sides of the exit of the heat preservation section 11 are symmetrically installed. Side plate 7, upper slideway 6 and glideway 10 are respectively fixedly installed on the casings of the front and rear sides of two bellows 8, and the movable side plates 7 on the left and right sides are installed between upper slideway 6 and glideway 10, which can Move left and right horizontally, the inner walls of the bellows 8 on the left and right sides and the four movable side plates 7 on the front and rear...

Embodiment 2

[0041] A wall-attached jet sealing pressure stabilizing device in the alloying process of galvanized strip steel, the device mainly consists of a bellows 8, a nozzle 5, a movable side plate 7, a spoiler 2, a supporting column 3, an upper slide 6, and a slide 10 Etc composition, galvanized steel strip width 1000mm.

[0042] like Figure 1~3 , the galvanized steel strip passes through the heat preservation section 11 through the steering roller 12 and the bellows 8 on the left and right sides of the exit of the heat preservation section 11 are symmetrically installed. Side plate 7, upper slideway 6 and glideway 10 are respectively fixedly installed on the casings of the front and rear sides of two bellows 8, and the movable side plates 7 on the left and right sides are installed between upper slideway 6 and glideway 10, which can Move left and right horizontally, the inner walls of the bellows 8 on the left and right sides and the four movable side plates 7 on the front and rea...

Embodiment 3

[0048] A wall-attached jet sealing and voltage stabilizing device in the alloying process of galvanized strip steel and its use method, the device mainly consists of a bellows 8, a nozzle 5, a movable side plate 7, a spoiler 2, a supporting column 3, and an upper slide 6 , glide path 10, etc., galvanized steel strip width 1000mm.

[0049] like Figure 1~3 , the galvanized steel strip passes through the heat preservation section 11 and the bellows 8 symmetrically installed on the left and right sides of the exit of the heat preservation section 11 through the turning roller 12, and four movable pieces are symmetrically installed on the front and rear sides of the exit of the galvanized strip steel heat preservation section 11. Side plate 7, upper slideway 6 and glideway 10 are respectively fixedly installed on the casings of the front and rear sides of two bellows 8, and the movable side plates 7 on the left and right sides are installed between upper slideway 6 and glideway 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com