Draining vehicle for transferring water meter workpieces

A technology for draining carts and workpieces, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., and can solve problems such as the inability to meet the requirements of automatic assembly of water meters, the lack of design of the transfer interface of the AGV dispatching system, and the inability to adjust the positions of workpieces. , to achieve the effect of improving work reliability and environmental adaptability, solving the inconvenience of external power supply, and having little influence from environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

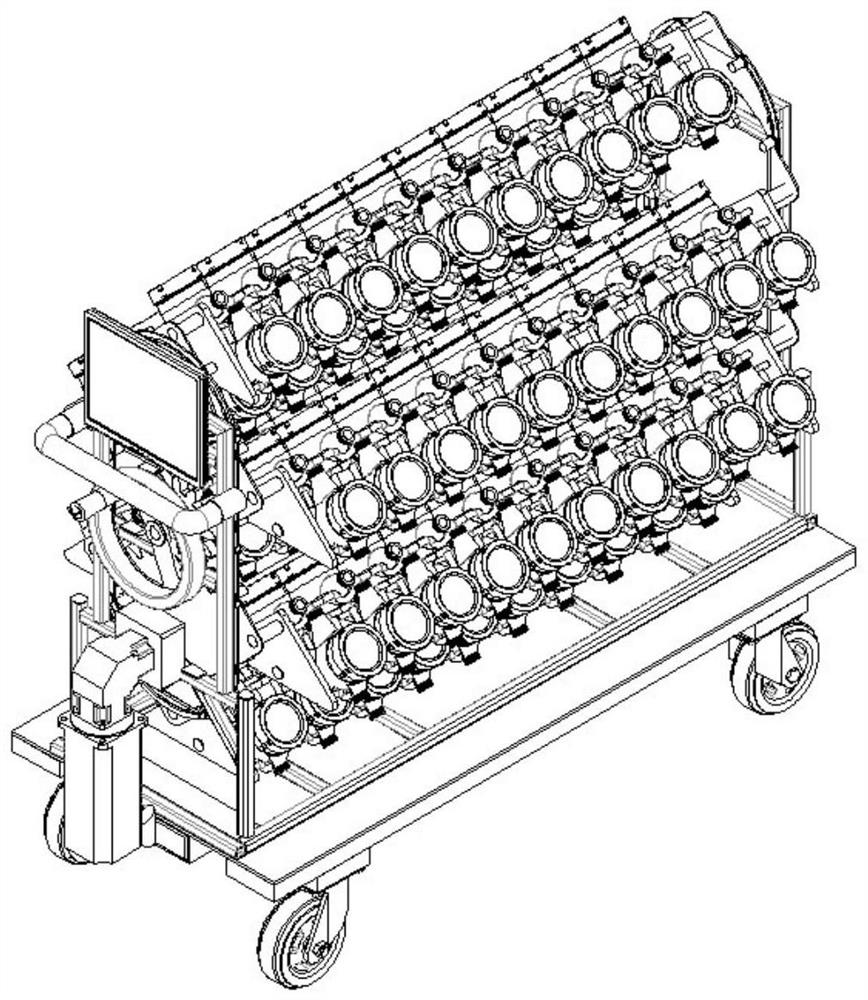

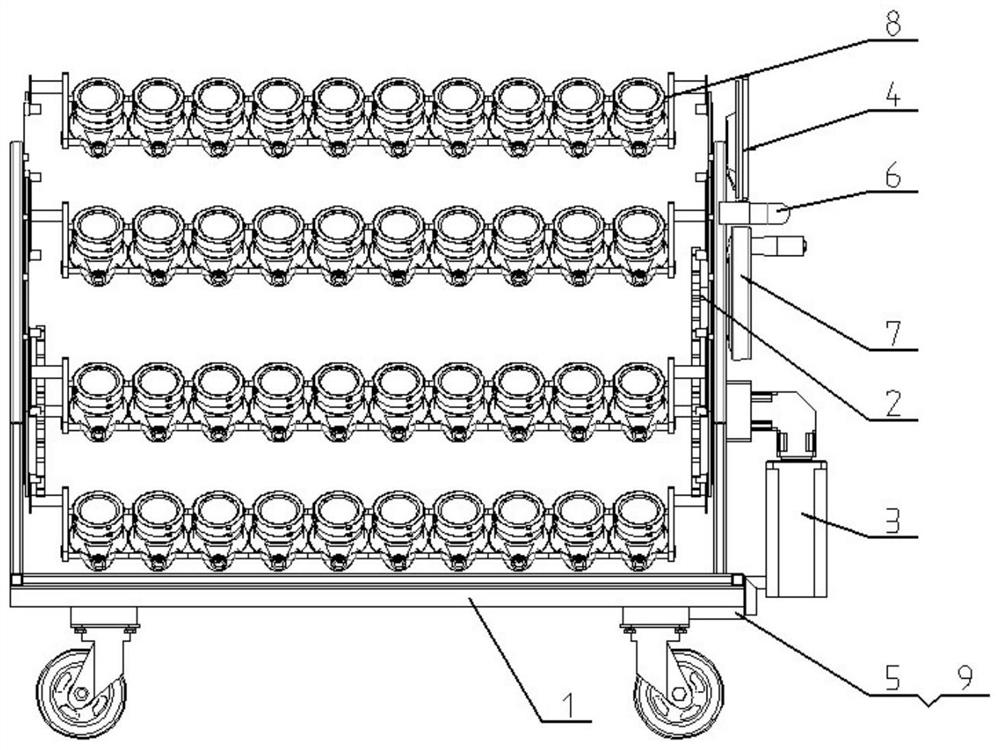

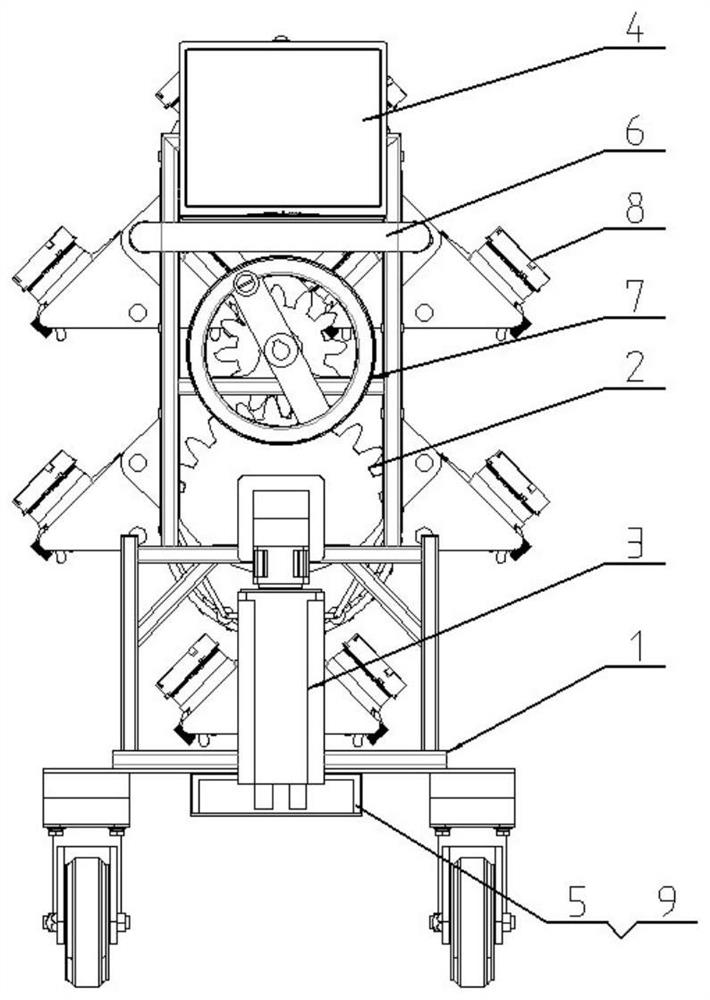

[0035] combine Figure 1 ~ Figure 4 , a water draining car used for water meter workpiece transfer, characterized in that it includes a car body frame 1, a transmission mechanism 2, a power system 3, a battery module 5, a hand wheel 7, a workpiece placement frame 8 and a control system 9;

[0036] Such as Figure 5 As shown, the car body frame 1 is composed of a support frame 11, a drain car chassis 12, a power supply cabinet 13, 2 directional wheels 14, 2 universal wheels 15 and an AGV dispatching system transfer interface, wherein the support frame 11 is installed on On both sides of the drainer chassis 12, the directional wheels 14 and the universal wheels 15 are respectively located at both ends of the bottom of the drainer chassis 12, the power cabinet 13 is located at the bottom of the drainer chassis 12 near the universal wheel 15, and the AGV dispatching system transfer interface Located at the bottom of the drainer chassis 12;

[0037] combine Figure 6 ~ Figure 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com