Wind tunnel test stand with unilateral aerodynamic force

A wind tunnel experiment and aerodynamic technology, which is applied in the aerospace field, can solve the problems of flutter and small stiffness of thin plates, and achieve the effect of simple and reliable structural design, high universality of parts and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

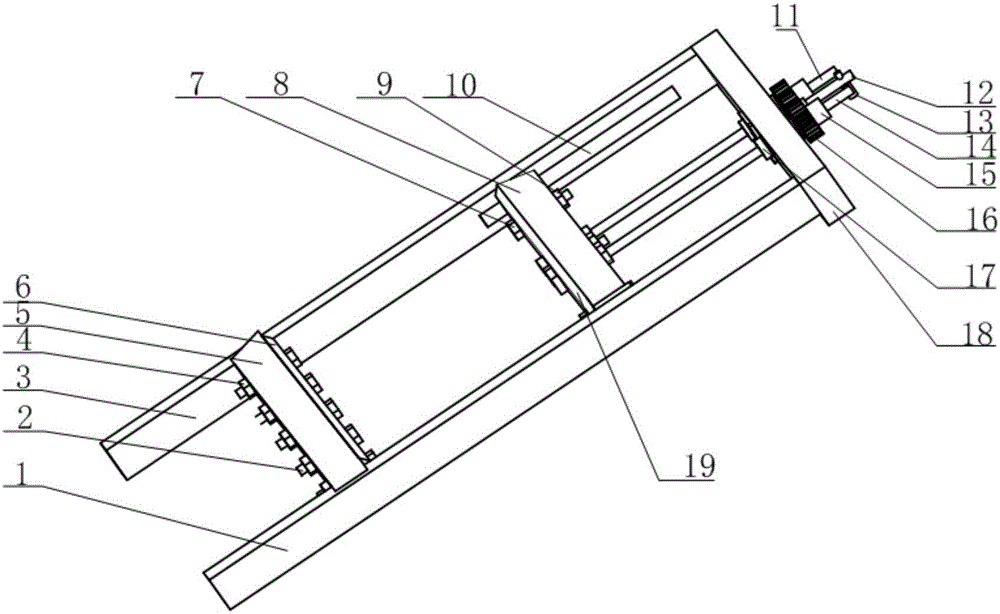

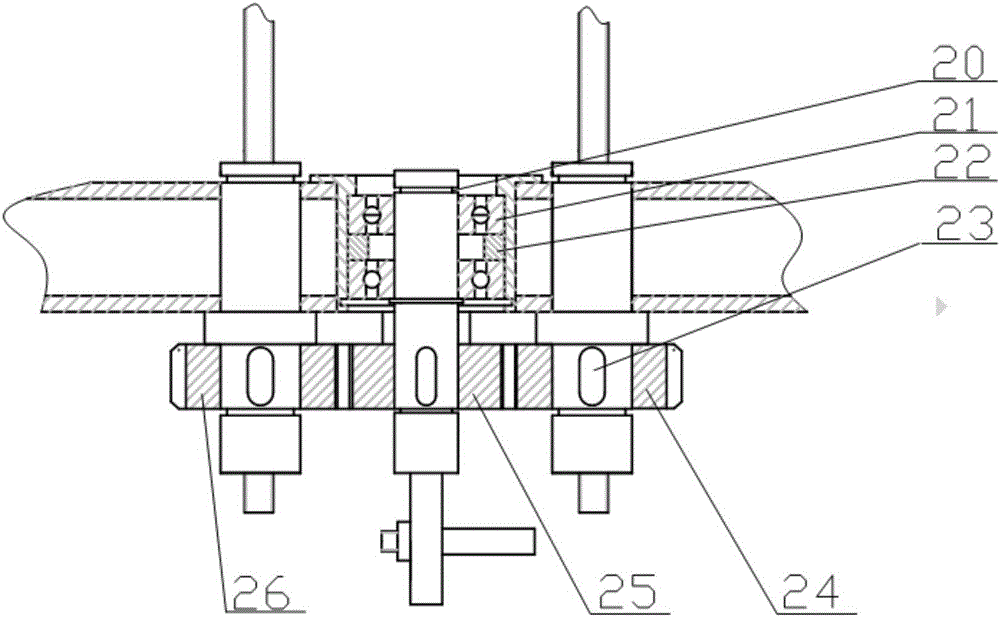

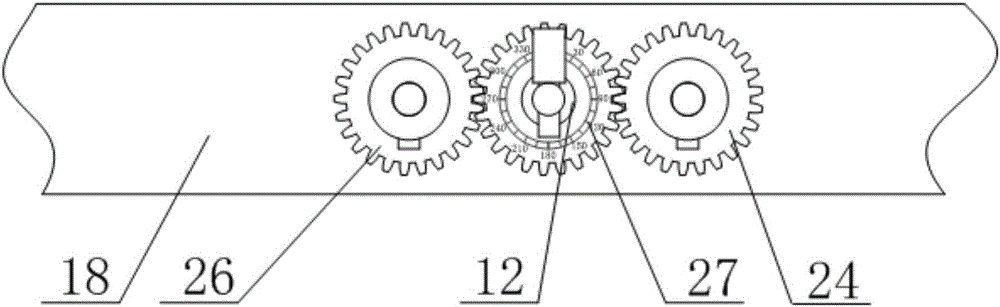

[0023] The unilateral aerodynamic wind tunnel test frame of the present invention has an overall structure such as figure 1 and 5 As shown, including right support plate 1, first bolt 2, left support plate 3, first nut 4, front deflector 5, front deflector splint 6, second bolt 7, rear deflector 8, second nut 9. Linear guide rail 10, first lead screw 11, handle guide rod 12, handle 13, second lead screw 14, cylindrical nut 15, gear 16, sleeve 17, rear support plate 18, rear deflector splint 19, spring coil 20, bearing 21, bobbin 22, key 23, right gear 24, intermediate gear 25, left gear 26, dial 27 and thin plate 28. The right support plate 1 and the left support plate 3 are placed in parallel, and the right support plate 1 and the left support plate 3 are welded together by the rear support plate 18 .

[0024] The front deflector 5 and the front def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com