Method and device for controlling welding hot cracking during welding by performing electromagnetic induction heating

An electromagnetic induction heating and thermal cracking technology, which is applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as weld defects, arcing, and metal softening in the heating zone, so as to reduce the tendency of welding thermal cracks and control welding heat. Cracks, Effect of Temperature Gradient Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

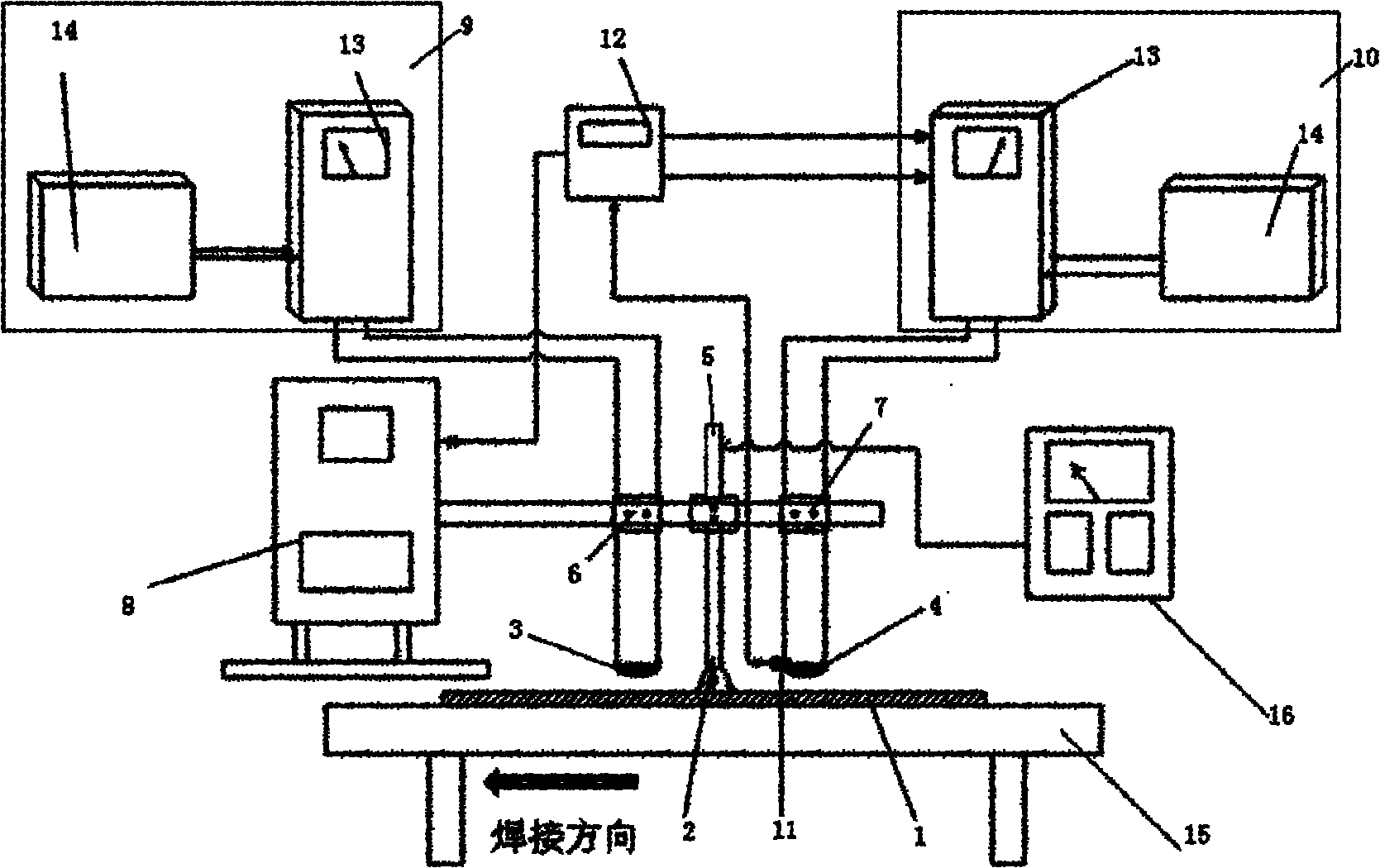

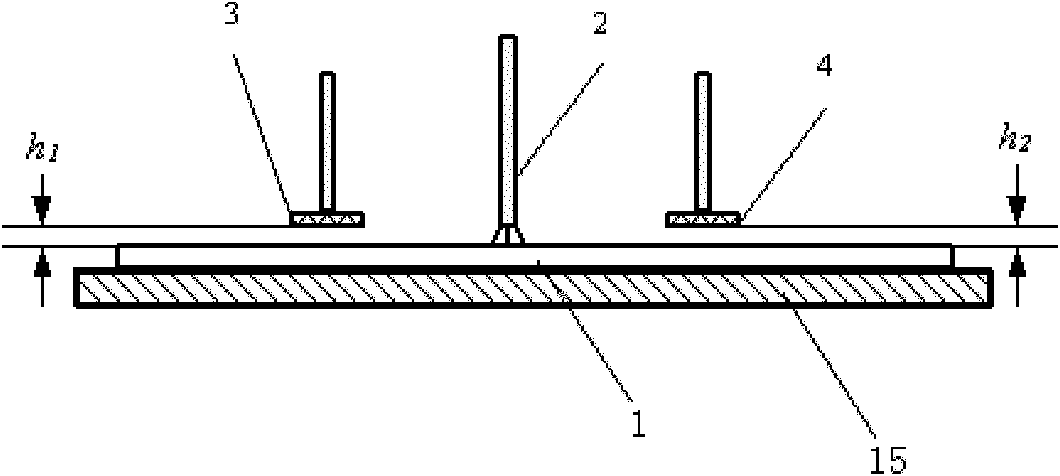

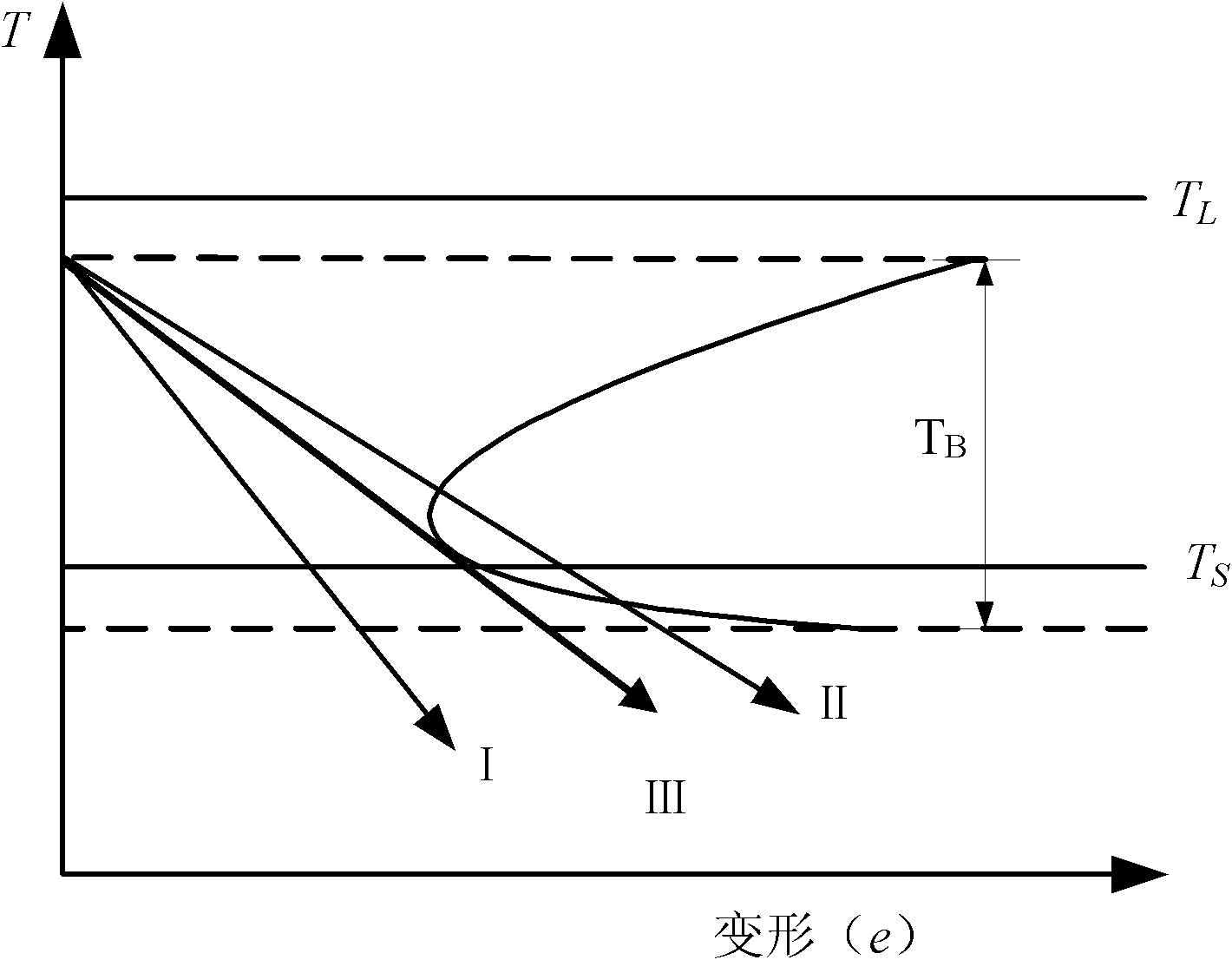

[0026] Such as figure 1 As shown, a device for controlling welding thermal cracks with welding electromagnetic induction heating includes a welding torch 2, a preheating coil 3 is arranged in front of the welding torch 2, a rear heating coil 4 is arranged at the rear of the welding torch 2, the welding torch 2, preheating Both the coil 3 and the post-heating coil 4 are arranged directly above the weld seam, arranged longitudinally along the center line of the weld seam, and the welding torch 2 is connected to a welding power source 16 . During the welding process, the preheating coil 3 first preheats the weld seam of the workpiece 1 to be welded, and then the heating coil 4 heats the weld seam being cooled to achieve the purpose of slow cooling until all welding is completed. This welding method can Reducing the overall or local temperature gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com