High-hardness roller processing method

A processing method and high hardness technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high processing cost, large consumption of grinding wheel, long time consumption, etc., achieve short processing time, improve work efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] The hardness of the roll used in this embodiment is 95HSD, the length of the roll body is 1450mm, and the diameter of the roll body is φ380mm. The lathe used is a C61125 lathe.

[0008] The processing method is as follows: ① The roll is placed on the lathe, and the CBN polycrystalline blade is used as a turning tool to rough process the roll at a cutting speed of 60 m / min, the feed rate is 1 mm / r, and the cutting depth is 1 mm; ② Then Using CBN polycrystalline inserts as turning tools, the rolls were semi-finished at a cutting speed of 120 m / min, the feed rate was 0.5 mm / r, and the cutting depth was 0.5 mm; ③ CBN polycrystalline inserts were used as turning tools to The roll was finished at a cutting speed of 210 m / min, with a feed of 0.3 mm / r and a depth of cut of 0.10 mm. The entire processing process can be completed in only 84 minutes, and the UT inspection of the roll surface and the eddy current inspection are all normal.

Embodiment 2~ Embodiment 5

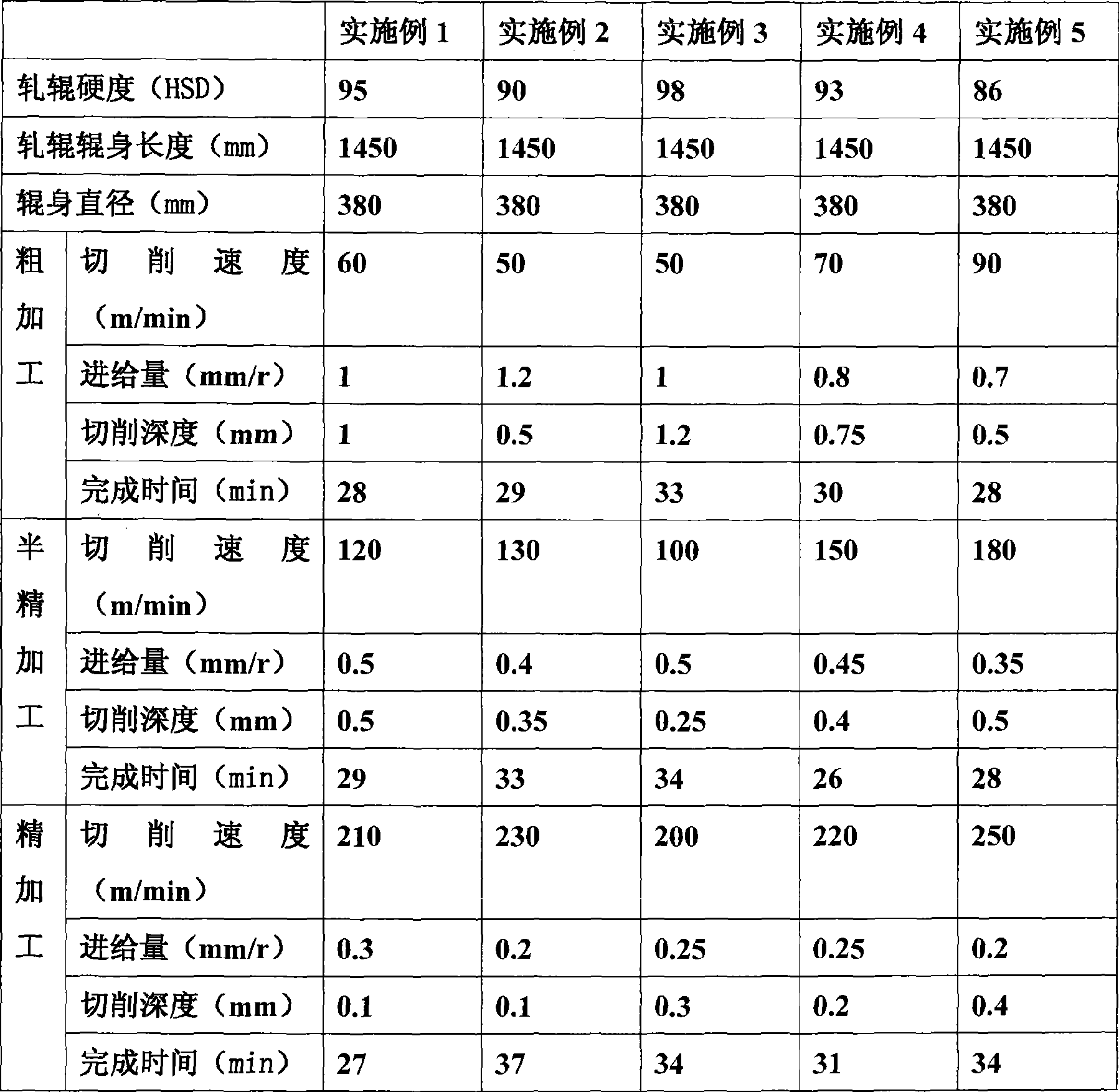

[0010] The processing method of each embodiment is basically the same as that of embodiment 1, and the difference is shown in Table 1.

[0011] Table 1

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com