Gas sealing device and method for soaking zone of continuous annealing furnace

A technology of continuous annealing furnace and soaking section, which is used in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems that the furnace pressure cannot be kept stable in the soaking section, and the rise of hot air flow cannot be effectively restricted, so as to prevent the hot air flow. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

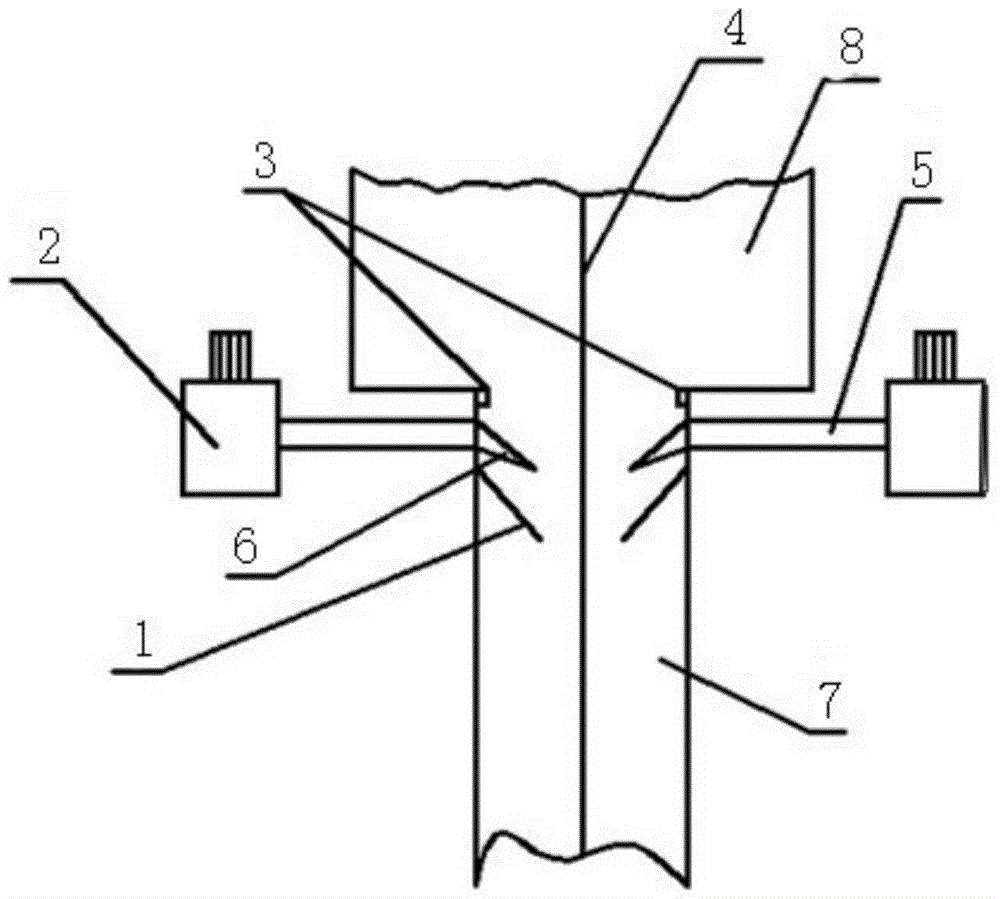

[0012] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] It includes two baffles 1 symmetrically arranged on the inner wall of the exit of the soaking section 7 of the continuous annealing furnace. The top of the top is connected to the inner wall at the outlet of the soaking section, and the inner wall above the top is respectively provided with an air supply port. The inner side of the air supply port is connected with a nozzle 6, and its outer side is connected with one end of the air supply pipe 5. The other end of the air supply pipe 5 A fan 2 is connected, and an infrared thermometer 3 is arranged on the inner wall above the nozzle 6 .

[0014] The distance between the bottoms of the two baffles 1 is 150mm-250mm, the nozzle 6 is a straight nozzle, the vertical distance between the outer edge of the nozzle and the baffle is 200mm-300mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com