Tool and method for clamping guide pipes by using hydraulic rubber bags

A technology of rubber bladders and hydraulic pipelines, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of affecting the quality of catheter end processing, difficult to clamp steel catheters, and pinch damage on the surface of catheters, so as to avoid tube The problem of eccentricity of the end, the flexible use method, and the effect of compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In this embodiment, an 0Cr18Ni9Ti steel conduit with an outer diameter of 27 mm and a wall thickness of 1 mm is clamped.

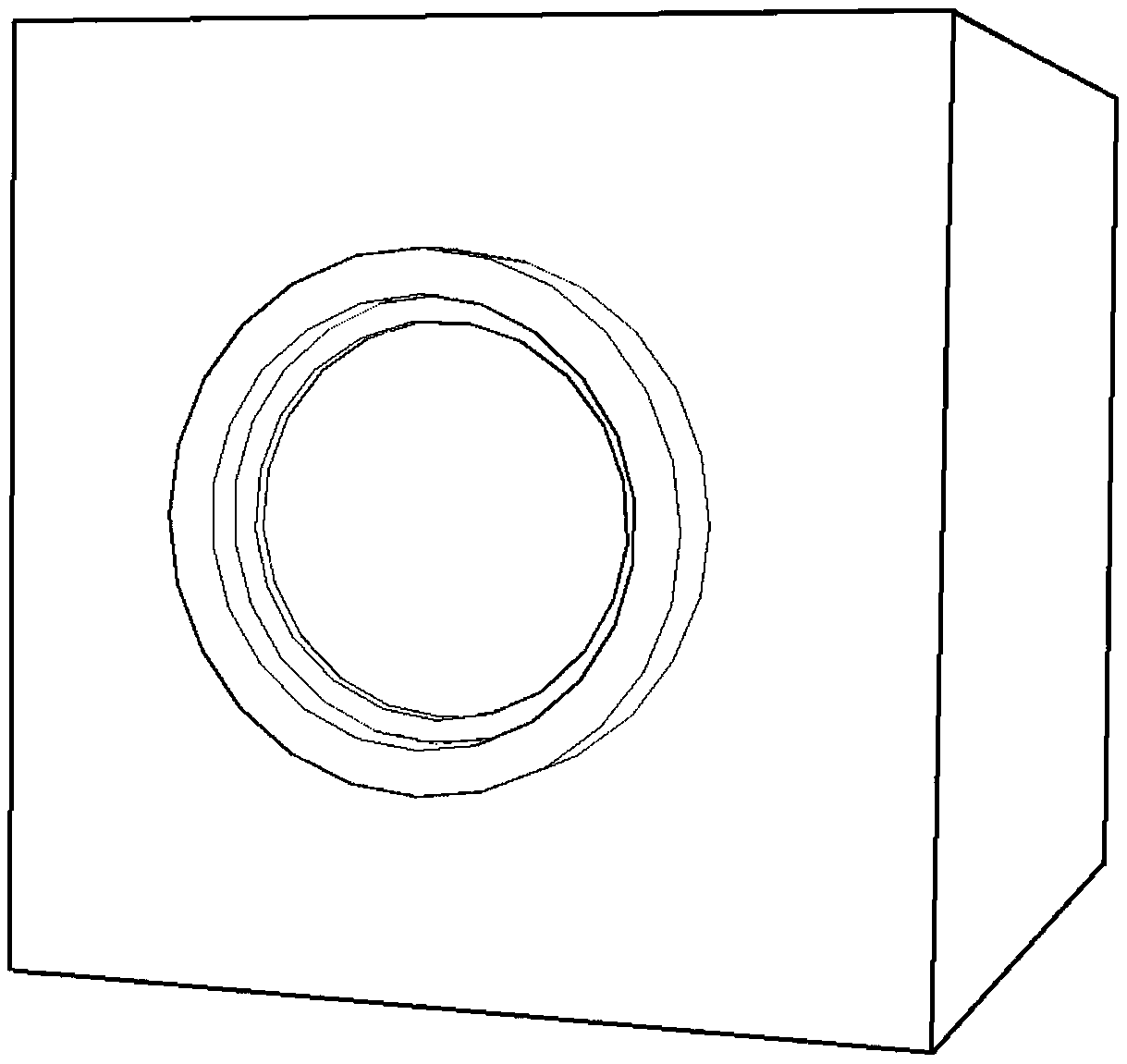

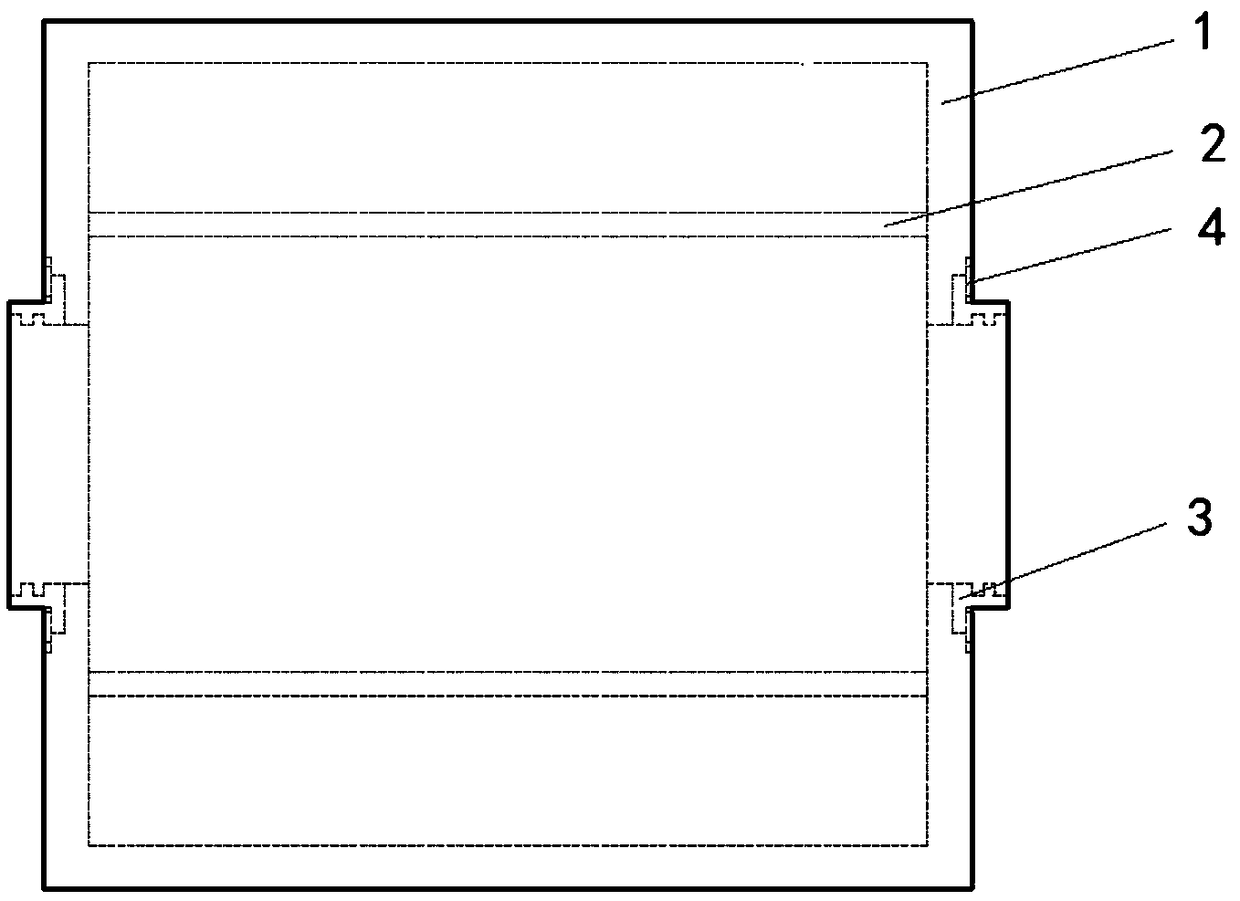

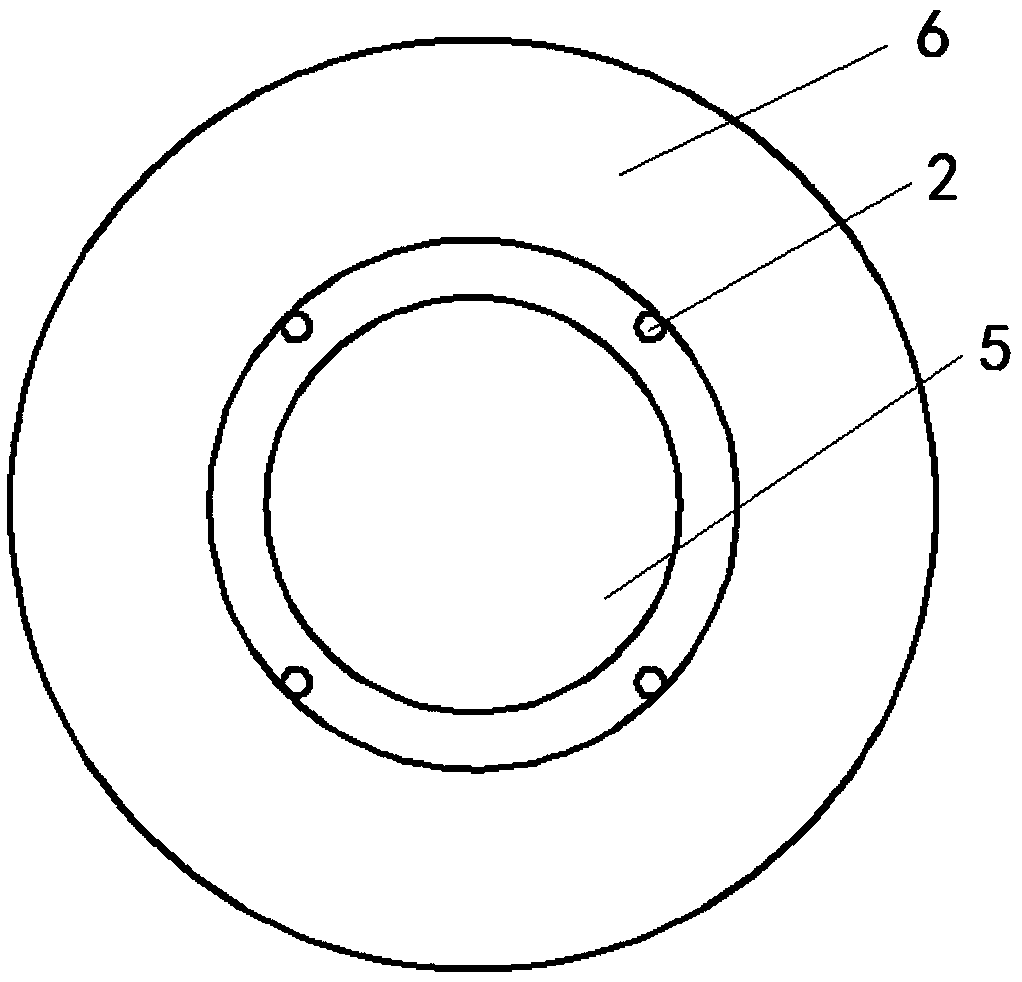

[0027] Such as figure 1 As shown in -5, a tool that uses a hydraulic rubber bag to clamp a catheter, including a box 1 with a built-in rubber bag 6 and a positioning ring 3, the box 1 is fixed on the workbench, and the entrances and exits of the catheter on the front and rear sides of the box 1 , is provided with a detachable and replaceable positioning ring 3, inside the box body 1, a hollow rubber bag 6 is fixed close to the inner wall, and a cross bar 2 for limiting the rubber bag 6 is provided, and the hydraulic pipeline 7 passes through the box The body shell connects the rubber bag 6 with the external hydraulic pump.

[0028] The method for using the tooling to clamp the conduit includes the following steps:

[0029] (1) According to the diameter of the conduit 5, select a positioning ring 3 with a suitable inner diameter, insert it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com