Film tearing mechanism

A technology of protective film and manipulator, applied in lamination auxiliary operation, lamination, layered products, etc., can solve the problem of easily damaged product surface, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

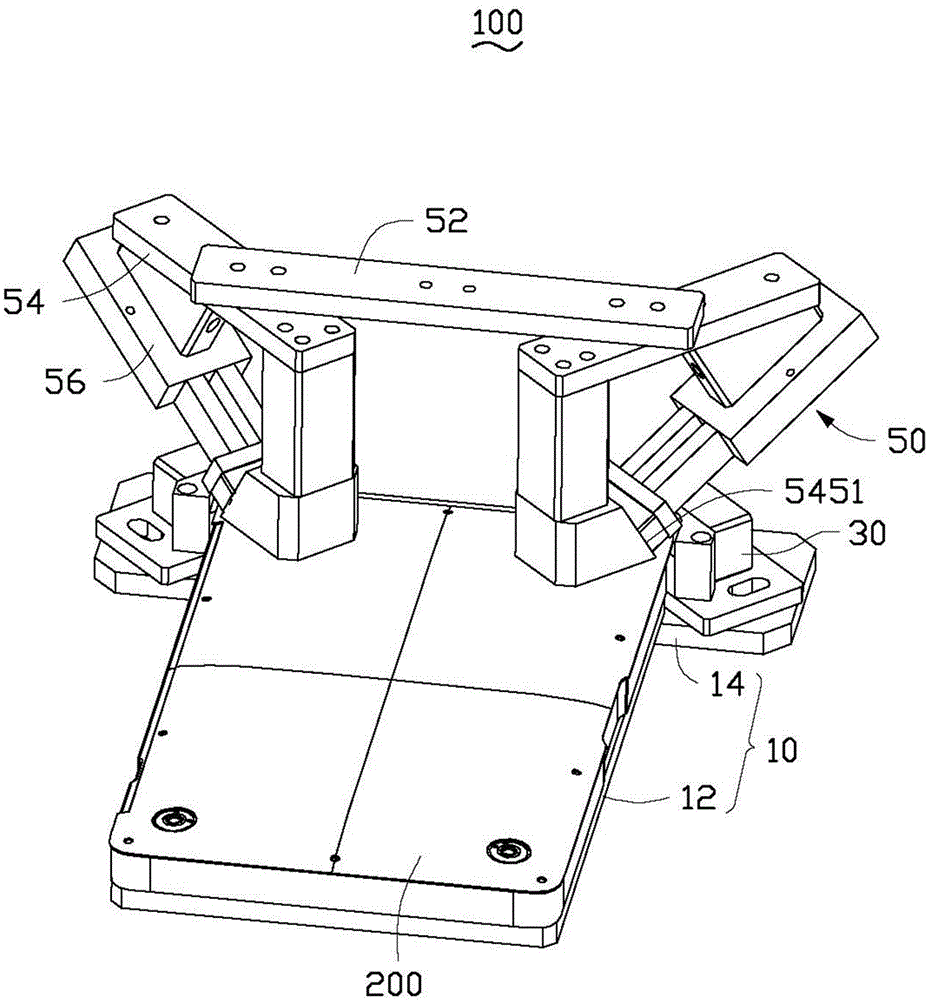

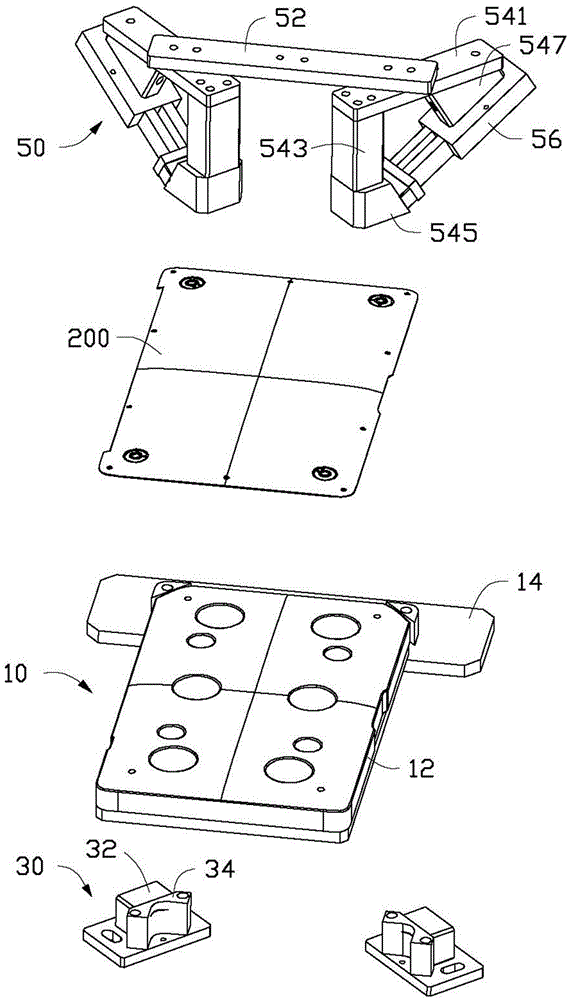

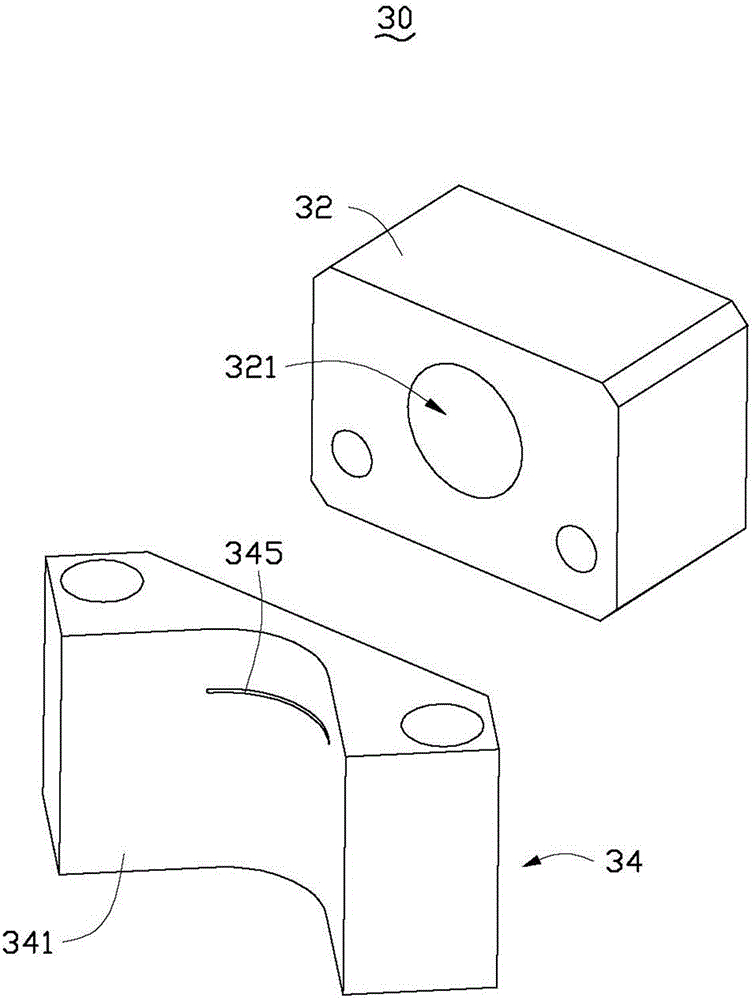

[0015] See figure 1 and figure 2 , The film tearing mechanism 100 of the embodiment of the present invention is used to assist a robot (not shown) to tear off the protective film (not shown) on the surface of the sheet-like workpiece 200. The film tearing mechanism 100 includes a fixing base 10, an air blowing assembly 30 arranged on the fixing base 10, and a clamping assembly 50 arranged adjacent to the air blowing assembly 30.

[0016] The fixing base 10 is roughly in the shape of a “T” plate, and includes a supporting portion 12 and two mounting portions 14 adjacent to the supporting portion 12. The carrying portion 12 is used to carry the workpiece 200. In this embodiment, the shape of the carrying portion 12 is adapted to the outer shape of the workpiece 200, and is roughly in the shape of a rectangular plate. The two installation parts 14 are respectively arranged adjacent to two adjacent corners of the supporting part 12, and are used for installing the air blowing assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com