3D (Three-dimensional) printing method based on micro-droplet inkjet gelation vascular stent

A vascular stent and 3D printing technology, applied in the field of 3D printing, can solve the problems of inability to accurately guarantee the material supply of the extrusion head, rough production process, and too fine printing structure, so as to save the support removal process, no support, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

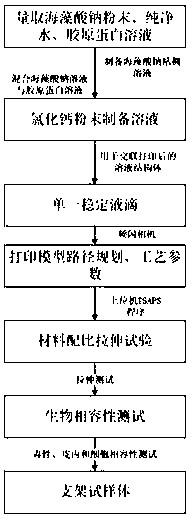

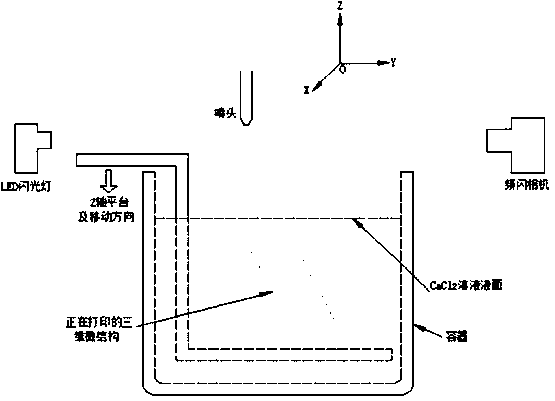

[0020] Such as figure 1 As shown, the present invention provides a method for 3D printing of a micro-droplet inkjet gelled vascular stent, comprising the following steps:

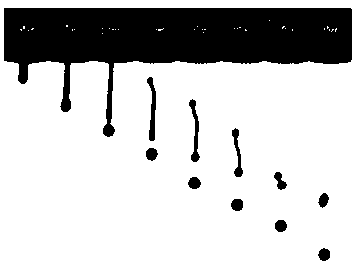

[0021] Step 1. Printing material preparation: The biological material used in the present invention is a mixture of sodium alginate viscous solution with a mass fraction of 1.0% and a collagen solution with a mass fraction of 0.5%, and the required mass fraction for gelation is 3.0% % calcium chloride solution. The configuration method is as follows: Sodium alginate solution configuration: use pure water, sodium alginate powder with a biochemical grade and a viscosity range of 200±20mpa·s; take the mixed phase of sodium alginate powder and purified water into a beaker and add collagen Solution, first shake it manually and then use an electromagnetic stirrer to stir at a constant speed until the sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com